Textures – USG Manufactured Housing Handbook User Manual

Page 14

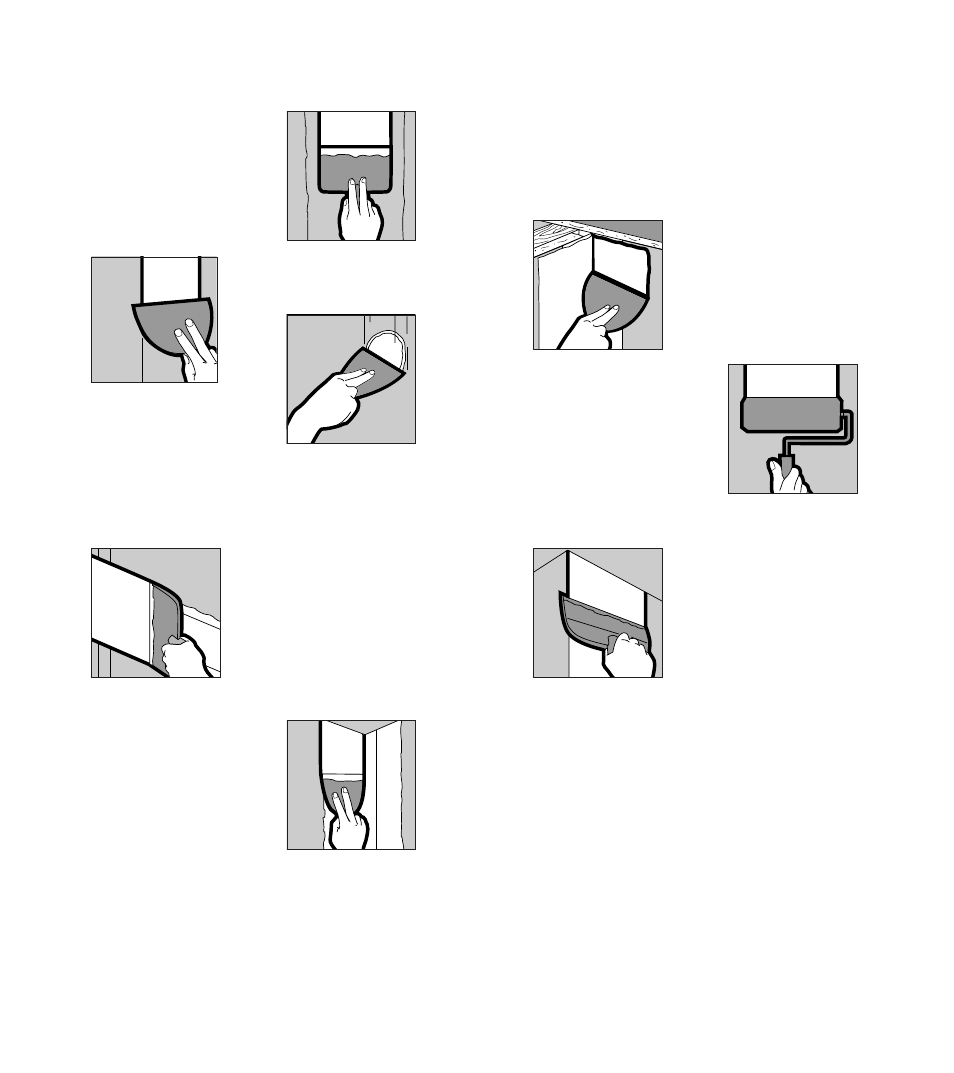

Flat Joints

Allow the first coat to set com-

pletely and to dry as much as

possible before proceeding.

Scrape off bumps, ridges, and

other imperfections with knife. Be

careful not to damage surface of

the gypsum board.

Apply S

HEETROCK

MH Brand

Lightweight Setting-Type Joint

Compound (T

UF

-S

ET

Lite) or

S

HEETROCK

Brand Lightweight

Setting-Type Joint Compound

(E

ASY

S

AND

) to tapered joints using

an 8

Љ-10Љ knife the length of the

joint.

Apply pressure to knife edge far-

thest from the joint and lift the

other edge just slightly above sur-

face. Draw knife down joint.

Repeat for opposite edge. This

technique is called feathering.

Joint compound should extend

beyond first coat for a total width

of 7

Љ or 8Љ. Apply a 7Љ-8Љ coat of

joint compound to each side of

butt joints and feather. Compound

should extend beyond first coat for

a total width of 14

Љ-16Љ.

Fasteners

Apply a second coat to fasteners

in same manner as first coat.

17 Second Coat, Inside Corners

Allow the first coat to set com-

pletely and to dry as much as

possible before proceeding. Apply

S

HEETROCK

MH Brand Lightweight

Setting-Type Joint Compound

(T

UF

-S

ET

Lite) on one side using a

6

Љ knife for the length of the cor-

ner. Scrape off any compound

that laps onto the second side.

Feather out beyond first coat and

allow to dry. After first side is dry,

apply compound on other side

and feather.

Tip

If you followed the tip for the first

coat on inside corners, you have

already finished the closed side of

the corner with a nonsandable

setting-type compound. At this

point, you can finish the open side

with a sandable compound (such

Textures

...............................................................................................................................

...............................................................................................................................

...............................................................................................................................

...........

...............................................................................................................................

...............................................................................................................................

...............................................................................................................................

...........

as T

UF

-S

ET

Lite or E

ASY

S

AND

Joint

Compound) as well as touching

up the closed side as needed. Be

sure to feather out the edges of

the compound (away from the

corner).

18 Second Coat, Outside Corners

and Metal Trim

Allow the first coat to set com-

pletely and to dry as much as pos-

sible before proceeding. Apply

second coat of S

HEETROCK

MH

Brand Lightweight Setting-Type

Joint Compound (T

UF

-S

ET

Lite) with

8

Љ-10Љ knife,feathering slightly

beyond first coat.

If you do not intend to texture the

panels you are finishing, skip

steps 19-24. Go to the “Smooth

Drywall Finishing” section and

begin with step 25 for instruc-

tions on applying a third coat.

The instructions that follow describe

various methods of creating textured

finishes on walls and ceilings. If you

are using a smooth finish for your

drywall surfaces, please skip ahead

to the section entitled “Smooth

Drywall Finishing.”

19 Preparation

For best results, apply a prime

coat of S

HEETROCK

Brand First Coat

after joint compound has set.

Allow prime coat to dry before

applying texture.

20 Choosing a Texture Product

Texture products are available in

machine-applied and hand-

applied types.

Machine-Applied Types

Aggregated powder textures are

spray-applied to an even thick-

ness for fast, complete coverage.

Textures are obtained with vari-

ous aggregates in suitable

binders. They are used to produce

fine to bold, heavy, acoustical-

look finishes. Unaggregated

types, also spray-applied, pro-

duce finer textures, ranging from

light spatter and fog-and-spatter

to medium-light finishes such as

orange peel or flat. Heavier

designs such as spatter and spat-

ter/knockdown may also be pro-

duced.

Hand-Applied Types

These include topping and all-pur-

pose compounds, plus multipur-

pose and ready-mixed textures.

Offer a good range of texture

...............................................................................................................................

...............................................................................................................................

...............................................................................................................................

...........

...............................................................................................................................

...............................................................................................................................

...............................................................................................................................

...........

...............................................................................................................................

...............................................................................................................................

...............................................................................................................................

...........

27

26

...............................................................................................................................

...............................................................................................................................

...............................................................................................................................

...........