Attaching the panels – USG Manufactured Housing Handbook User Manual

Page 6

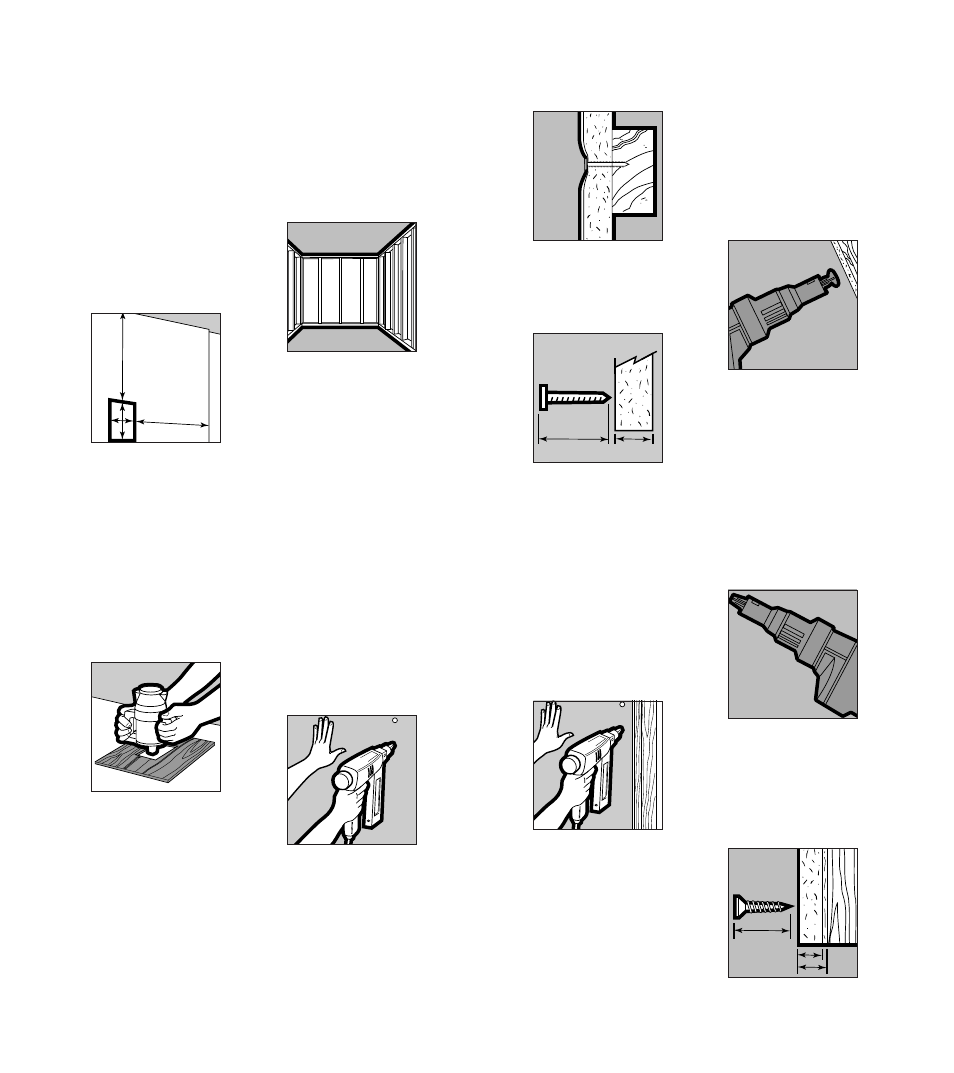

3 Cutouts

For openings such as doors, win-

dows, electrical outlets, and

switch boxes, measure across

from the point where the side

edge of the panel will rest to the

near and far sides of the required

opening. Then measure from the

point where the top or the bottom

edge of the panel will fall to the

top or bottom of the opening.

Mark the outline of the opening at

the appropriate position on the

gypsum panel. A template made

from thin plywood is useful for

repetitive cutouts.

Cut with a heavy-duty router

using either a bushing or bearing

to follow a template or a plunge

bit with an integral guide to follow

the framing in large openings.

4 Framing

Prior to panel attachment, inspect

framing to ensure that the face of

the framing is straight. Warped or

crooked framing should be

replaced.

5 Mechanical Attachment

Nail Attachment

Pneumatic nailing equipment may

be used for attaching gypsum

panels if the gun is equipped with

a depth-limiting stop. Do not rely

on air-pressure adjustments to

control nail depth.

Hold panel tight against framing.

Nail in a pattern that works the

gypsum panel flat against the

framing. Begin with restrained

edges and ends and work out-

ward toward open areas. Space

nails maximum of 7

Љ apart on

ceilings, 8

Љ on walls, and at least

3/8

Љ from ends and edges of pan-

els.

Seat nail so head is in a shallow

dimple (1/32

Љ) in the face of the

drywall.

Attaching the Panels

...............................................................................................................................

...............................................................................................................................

...............................................................................................................................

...........

...............................................................................................................................

...............................................................................................................................

...............................................................................................................................

...........

For 1/4

Љ, 3/8Љ, and 1/2Љ thick

panels, use 1-1/4

Љ annular ring

drywall nails. For 5/8

Љ panels, use

1-3/8

Љ annular ring drywall nails.

Drive nails in straight, not at an

angle. Do not overdrive or coun-

tersink nails. This results in

breaking the face paper or frac-

turing the gypsum core. If a nail

happens to go in crooked, hold

the panel tight against the fram-

ing and drive a second nail in

about 2

Љ from the nail that punc-

tured the paper. Then drive the

first nail in below the surface of

the board.

Screw Attachment

Space screws maximum of 12

Љ

apart on ceilings, 16

Љ on walls,

and at least 3/8

Љ from ends and

edges of panels. Sink screws to

just below the panel surface,

leaving the paper intact.

Use an electric or pneumatic

screwgun equipped with an

adjustable screw depth control

head and Phillips bit. Drive

screws in straight, leaving the

screwhead slightly (1/32

Љ) below

the face of the gypsum board. Be

careful not to overdrive screws.

Breaking the face paper greatly

lessens the holding power of the

screw.

On 3/8

Љ and 1/2Љ thick panels,

use 1-1/4

Љ screws; on 5/8Љ thick

panels, use 1-5/8

Љ Type W Bugle

Head Screws for superior holding

power and high resistance to

popping due to wood shrinkage.

...............................................................................................................................

...............................................................................................................................

...............................................................................................................................

...........

...............................................................................................................................

...............................................................................................................................

...............................................................................................................................

...........

...............................................................................................................................

...............................................................................................................................

...............................................................................................................................

...........

11

10

...............................................................................................................................

...............................................................................................................................

...............................................................................................................................

...........