Smooth drywall finishing – USG Manufactured Housing Handbook User Manual

Page 17

were not a problem. However, do

not leave any during the applica-

tion of this final coat or they will

mar the finished surface.

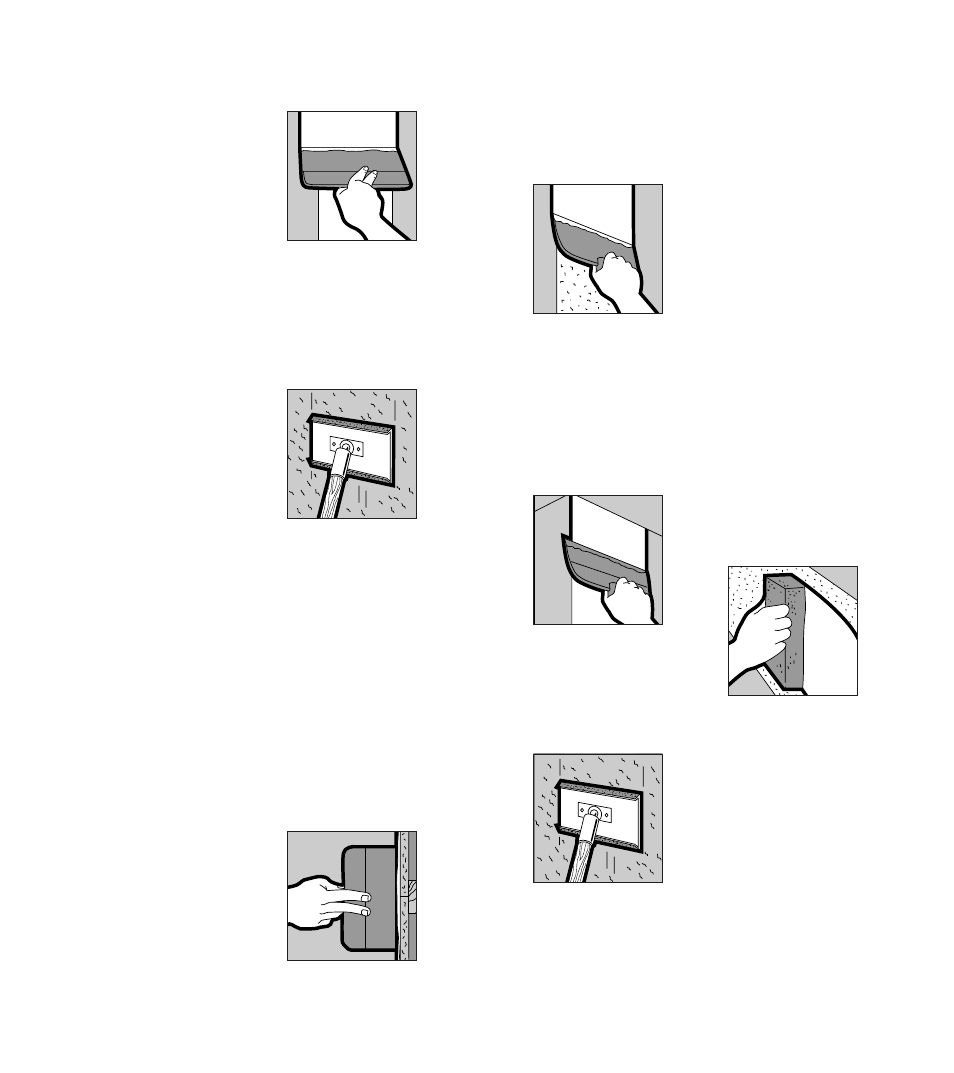

26 Third Coat, Outside Corners

and Metal Trim

Allow second coat to dry as com-

pletely as possible. Sand lightly if

necessary.Apply third coat of

S

HEETROCK

MH Brand Lightweight

Setting-Type Joint Compound (T

UF

-

S

ET

Lite) with 10

Љ knife,feathering

slightly beyond second coat.

27 Sanding

Allow third coat to dry. Lightly

sand imperfections in finished

joints, corners and over fastener

heads. Carefully remove sanding

dust with damp sponge.

Tip

Use a fine-grit sandpaper in a

tool designed for drywall sanding

so you don’t dig into the joint

compound. For best results, use

#120-grade or finer sandpaper

(#200 grade or finer mesh cloth)

when sanding conventional-

weight all-purpose joint com-

pounds. For topping and light-

weight joint compounds, use

#150-grade or finer sandpaper

(#220-grade or finer mesh cloth).

Avoid roughening the surface

paper when sanding. If you do

roughen it by accident, repair the

damage by applying a little joint

compound with a 6

Љ knife.

Wet Sanding

When only minimal sanding is

needed, try wet sanding with a

sponge. It eliminates dust and

does not scuff the surface paper.

Use a small-celled polyurethane

sponge similar in appearance to

carpet padding. Saturate sponge

and wring to prevent dripping. Rub

joints to remove high spots, using

as few strokes as possible. Clean

the sponge frequently during use.

28 Storage and Cleanup

Before storing unused drying-

type joint compound, clean sides

and lid of container so no dried

compound falls into the mixture.

Level drying-type joint compound

surface with knife and cover con-

tainer tightly. If storing for a long

time, cover surface of joint com-

pound with approximately 1/2

Љ of

clean water and cover container.

Do not store in direct sunlight or

where freezing conditions may

occur. Pour off water before

using stored joint compound.

Clean tools with warm, soapy

water.

...............................................................................................................................

...............................................................................................................................

...............................................................................................................................

...........

...............................................................................................................................

...............................................................................................................................

...............................................................................................................................

...........

...............................................................................................................................

...............................................................................................................................

...............................................................................................................................

...........

33

Glitter Effects

Sparkle, particularly under artificial

light, can be added to ceilings for

unusual and interesting effects

with the use of glitter. Glitter comes

in 1/32 to 1/16 in. cuts in silver,

gold, blue, red, fuschia, or green,

and is applied with hand-cranked

or air-powered guns. Application

usually consists of embedding glit-

ter in the freshly applied ceiling

texture while surface is still wet.

Depending on effect desired, fig-

ure 1 lb. of glitter per 500 sq. ft. of

ceiling.

If you have applied texture to your

panels, skip the following instruc-

tions for completing a smooth fin-

ish. Go to step 28 for storage and

cleanup information.

Smooth Drywall Finishing

If you have skipped the Texturing

section because you wish to create a

smooth drywall finish, the steps that

follow will guide you through the

completion of the smooth-finishing

process.

25 Third Coat, Flat Joints and

Fasteners

Allow second coat to dry as com-

pletely as possible. If necessary,

remove imperfections with knife

or sandpaper. Apply a thin finish-

ing coat of S

HEETROCK

MH Brand

Lightweight Setting-Type Joint

Compound (T

UF

-S

ET

Lite) or

S

HEETROCK

Brand Lightweight

Setting-Type Joint Compound

(E

ASY

S

AND

) with a 12

Љ knife to the

flat joints and a 6

Љ knife to the

fastener heads. Press knife firmly

so joint compound fills depres-

sions but does not significantly

add to thickness. Feather edges

at least 2

Љ beyond second coat.

Tips

Do not sand unless it is necessary.

If you do sand, use fine-grit sand-

paper on fully dry compound, and

be careful not to scuff the gypsum

panel paper to minimize surface

touch-up requirements.

Before applying the final coat,

check to see if tapered joints are

level with surface. Hold the 10

Љ

blade across the joint, straight out

from the wall. If the blade can be

rocked across the joint, the joint is

crowned. It must be hidden by

feathering the final coat out as far

as possible.

Use the “splitting” technique

(described in the section on sec-

ond coats) to make the slope of

the compound from the crown to

the surface of the board as grad-

ual as possible.

When applying earlier coats,

minor depressions and grooves

Smooth Drywall

Finishing

...............................................................................................................................

...............................................................................................................................

...............................................................................................................................

...........

...............................................................................................................................

...............................................................................................................................

...............................................................................................................................

...........

32

...............................................................................................................................

...............................................................................................................................

...............................................................................................................................

...........