USG Industrial Plasters and Gypsum Cements for Foundry Applications User Manual

USG For Home

USG Metal Casting Plaster

A blend of plaster and refractory materials

formulated for producing low-permeability plaster

molds. Designed for casting aluminum matchplatyes,

cope-and-drag sets, core boxes, loose patterns,

prototypes, housings and plastic mold tooling.

HYDROPERM Gypsum Cement

A formulated product incorporating an air-

entraining agent to provide permeability. For

producing permeable plaster molds to cast many

non-ferrous metals and alloys.

Medium High-Expansion HYDROCAL Cement

A formulated product to give uniform expansion of a

pattern in all directions, equal to the shrinkage of

aluminum or zinc alloy metals (Kirksite, Zamac,

etc.). Normal growth range is

1

⁄

16

to

3

⁄

16

inch per foot.

The Plaster Mold Casting Process

Is Superior To Other Methods When . . .

• You need fine, intricate surface detail.

• You want to use parts in an as-cast condition.

• You want to reduce or eliminate post-machining of

castings.

• You need better dimensional accuracy for cast-to-

size parts.

• You need to cast thin metal sections, not possible

with other methods.

• You need to produce complicated shapes with

intricate core structures.

• You cannot justify the higher pattern or die costs

required by some casting methods.

• You want to do short run or prototype castings

economically.

IG-279/10-92

Industrial Plasters and Gypsum Cements for Foundry Applications

Trademarks: The following trademarks used herein are owned by USG

Corporation or its subsidiaries: USG, HYDROPERM, HYDROCAL.

Note: Products described here may not be available in all geographic markets.

Consult your local representative for information.

Notice: We shall not be liable for incidental and consequential damages,

directly or indirectly sustained, nor for any loss caused by application of these

goods not in accordance with current printed instructions or for other than

the intended use. Our liability is expressly limited to replacement of defective

goods. Any claim shall be deemed waived unless made in writing to us within

thirty (30) days from date it was or reasonably should have been discovered.

Copyright 1992, United States Gypsum Company

Printed in U.S.A.

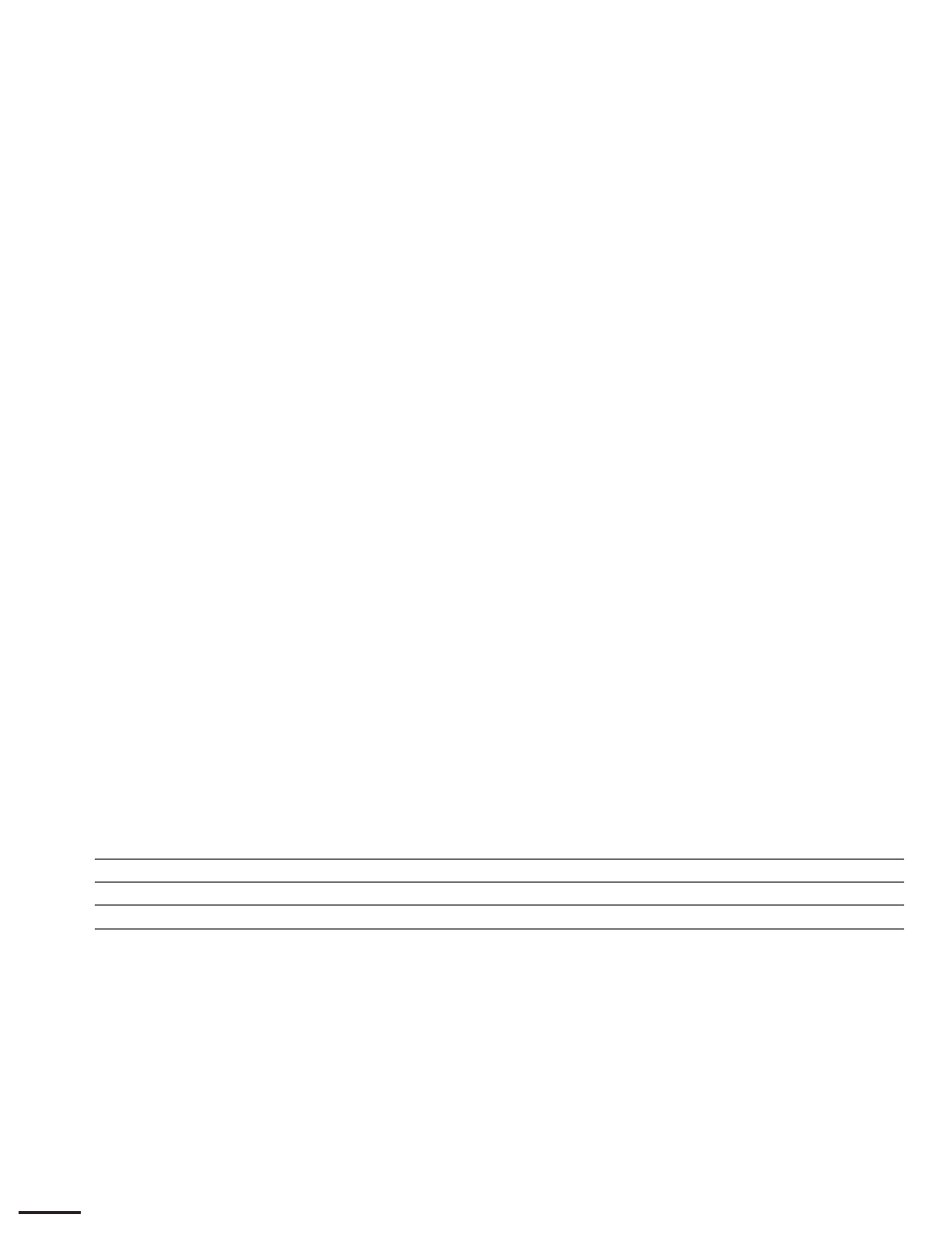

Typical Physical Properties

Use consistency

Maximum

(parts of water

Hand mix

setting

Approximate density

by weight per 100

setting time

expansion

(lb./ft.

3

)

Product

parts of plaster)

(minutes)

(%)

Wet

Dry

USG Metal casting plaster

130

25-30

0.100

84.6

41.0

Medium high-expansion H

YDROCAL

cement

48

25-35

1.050

108.7

—

H

YDROPERM

gypsum cement

100

12-19

0.140

40.0

—