Finishing panels – USG Manufactured Housing Handbook User Manual

Page 11

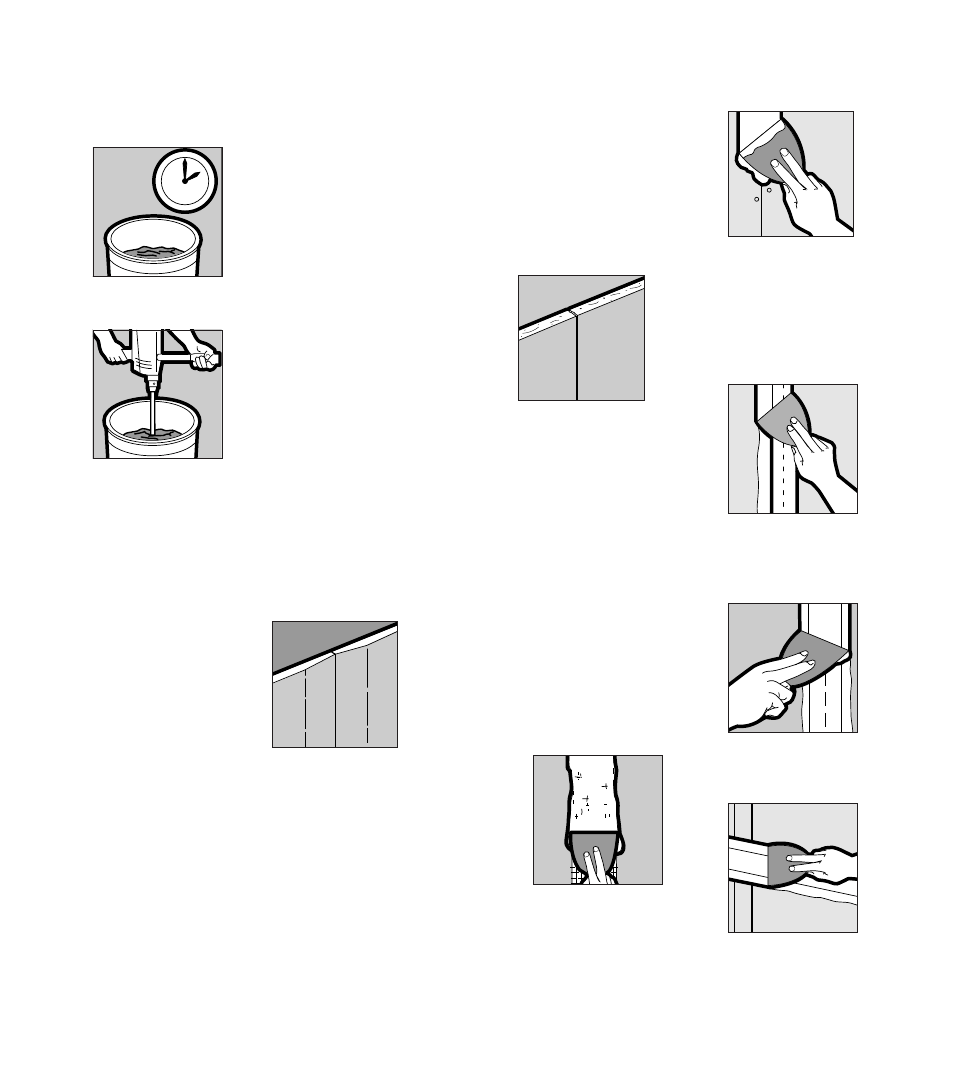

Permit to soak for the time indi-

cated on the product package.

Remix thoroughly to an even con-

sistency.

The amount of finishing work

required depends on the skill of the

applicator and the desired appear-

ance of the final unit. Textured sur-

faces typically require fewer joint

treatment coats. Smooth drywall fin-

ish requires more steps, higher

applicator skills, and special primers.

It is also important that you under-

stand the differences among the

three main types of joints you will be

treating. Corners, also called angles,

are easy to identify. These are the

joints that occur where two panels

meet at an angle, as in the corner of

a room. Joints that occur where two

panels meet in the same plane are

known as flats. There are two kinds

of flats: tapered joints and butt joints.

Tapered joints occur where the fin-

ished edges of two boards meet. The

tapers pressed into the boards pro-

vide a depression so that the tape

and joint compound won’t create a

bump—known as a crown—above

the surface of the board.

Finishing Panels

...............................................................................................................................

...............................................................................................................................

...............................................................................................................................

...........

...............................................................................................................................

...............................................................................................................................

...............................................................................................................................

...........

Butt joints occur where the cut

edges of two panels butt together.

Because there are no tapers at butt

joints, the tape and compound will

automatically lie on top of the sur-

face of the board. This means that

butt joints are always naturally

crowned, and will require a slightly

different finishing procedure.

We recommend using a fiberglass

mesh tape, such as T

UF

-T

APE

, for fin-

ishing flat, tapered joints, and a paper

tape, such as S

HEETROCK

Brand Joint

Tape, for butt joints and corners.

12 First Coat, Flat Joints

Fiberglass Mesh Tape (such as

S

HEETROCK

MH Brand Joint Tape—

T

UF

-T

APE

)

Apply tape centered over the

joints and press in place using a

6

Љ joint knife.Apply S

HEETROCK

MH

Brand Setting-Type Joint

Compound over the tape using

sufficient pressure to force the

compound through the tape into

firm contact with the gypsum

board.

Paper Tape (such as S

HEETROCK

Brand Joint Tape)

Start with butt joints. Apply an

even, thin coat of

S

etting-type

joint compound for the length of

the joint with a 6

Љ finishing knife.

Center and lightly press tape into

wet joint compound with fingers.

Draw 6

Љ knife firmly along joint to

tightly embed tape. Be sure there

is sufficient joint compound under

tape to prevent blistering of the

tape.

While embedding the tape,

remove excess joint compound

from edge and apply as a thin

coat over the tape.

To finish tapered joints, follow

same procedure. Tape should

overlap tape applied to butt joints.

...............................................................................................................................

...............................................................................................................................

...............................................................................................................................

...........

...............................................................................................................................

...............................................................................................................................

...............................................................................................................................

...........

...............................................................................................................................

...............................................................................................................................

...............................................................................................................................

...........

21

20

...............................................................................................................................

...............................................................................................................................

...............................................................................................................................

...........