Aeris installation and service manual – STEMCO Aeris User Manual

Page 18

Aeris Installation and Service Manual

Page 18 of 42

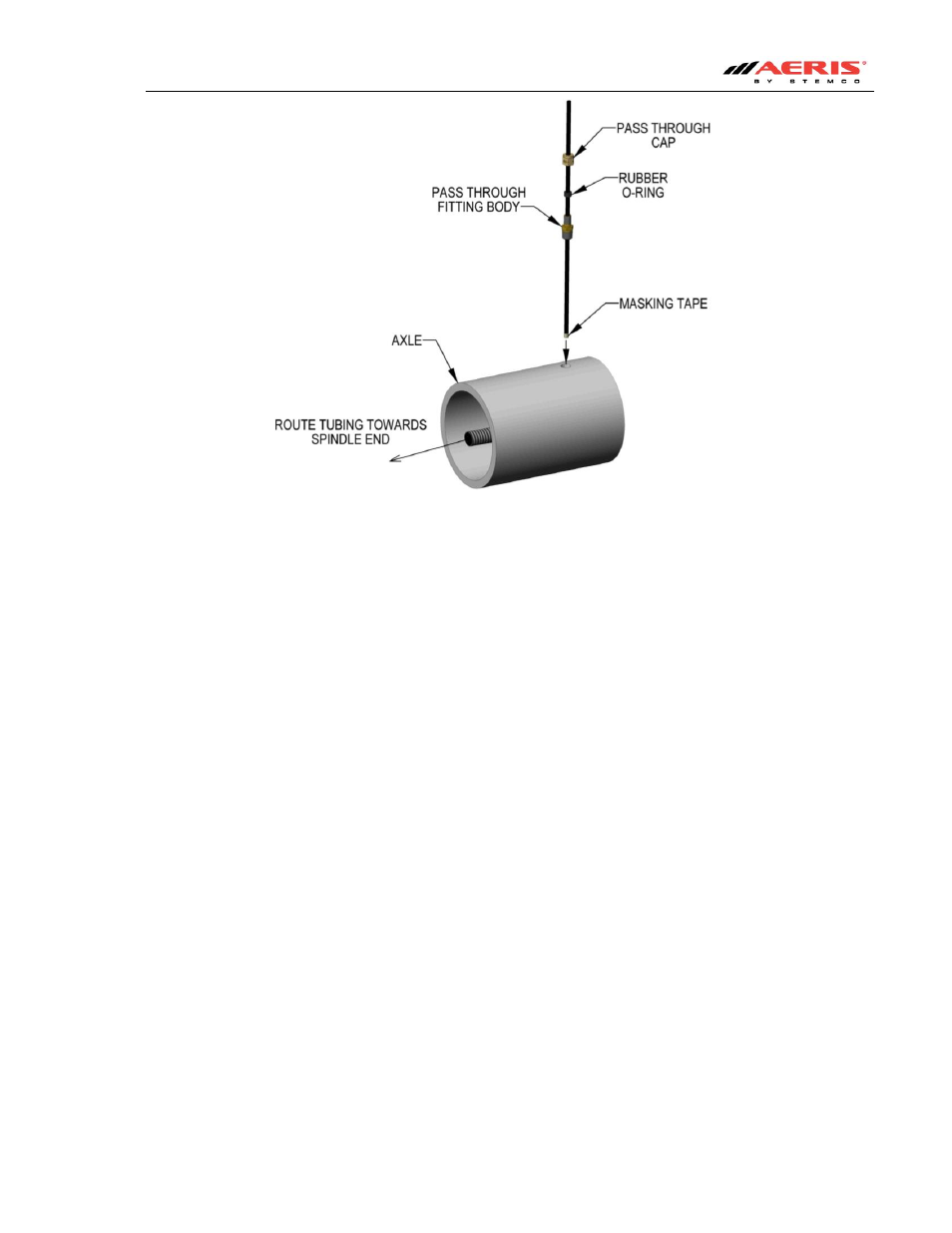

Figure 12

• Push the cap, O-ring and pass through fitting back approximately 5” in preparation for threading the airline

though the axle.

• Route the air line through the axle towards the spindle end on each of the outer tapped holes until airline

is protruding approximately 8” out of the spindle. If airline hangs up inside the axle, you may need to use

something to help fish it through the spindle end. Make sure the airline doesn’t have any kinks in it.

Split Loom Tubing Protection Installation

• Place one of the supplied split loom tubing protection sleeves over the airline tubing of each spindle end to

help protect against sharp edges inside the axle. Repeat steps 1-4 on remaining axle wheel ends.

• The air line from the spindle end going to the fitting on the axle fitting can now be cut. Make sure to cut

the tubing long enough to reach just past the center of the axle. The airline will be attached to a tee fitting

and then tie-wrapped to the center axle vent line. See Figure 13

Center Vent Line Installation

• Install the push lock fitting (1/4” NPT x 3/8” tubing) into the center tapped hole and tighten. Insert the

supplied 37” X 3/8” nylon tubing with the duck-bill into the fitting. The vent line should be oriented so the

duck bill is pointing up and tie-wrap it to frame or hoses of trailer where it’s not going to be part of any

moving component. If this option is not possible the vent line can be routed around the axle. Make sure

the tubing goes around the axle 1-2 times.

• Tie wrap and secure the end of the air line with the duck bill to the airline coming out of the axle. Make

sure the duck bill vent is facing up and there aren’t any big loops of airline hanging below the axle to snag

on anything as trailer is moving. Repeat this step on all axles where Aeris is being installed.