STEMCO Aeris User Manual

Page 10

Aeris Installation and Service Manual

Page 10 of 42

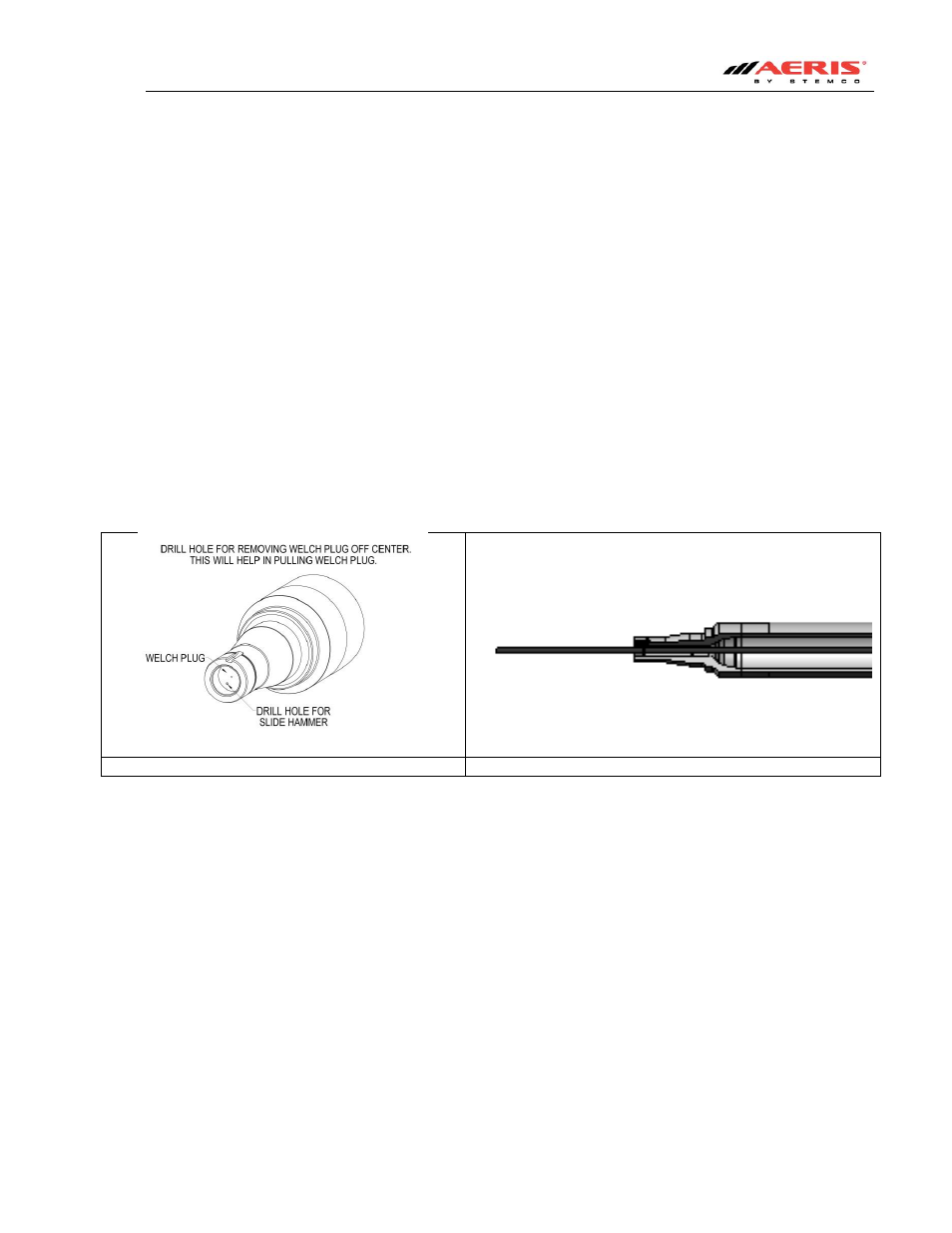

Welch Plug Removal

Remove welch plugs. Drill a small hole off center in welch plug. Hole should be smaller than plug removal

spear on the end of slide hammer. Using a slide hammer fitted with a welch plug removal spear to remove

the welch plug. Be careful not to score the inside diameter of the spindle bore.

If you do not have a slide hammer you may be able to remove the welch plug by using a chisel and hitting the

welch plug off center. This should cause the plug to start turning inside the spindle unless there is a shoulder

behind the welch plug. Once the plug has turned enough to grab it with a pair of pliers and pull until plug

comes out.

If plug cannot be removed, drill a 1/2” hole in the welch plug. Make sure as you are drilling the hole you

don’t score the inside diameter of the spindle bore.

Insert a long steel rod into the 1/2" hole until it hits the back side of the welch plug in the opposite spindle.

Steel rod must be longer than the length of the axle. Use a hammer to hit the rod and knock the welch plug

out. Pull rod out and repeat procedure on the plug with hole with the 1/2" hole in it. Repeat procedure for

second axle. See Figure 2

Drill hole off center for slide hammer or rod.

Rod running through axle to other welch plug

Figure 2

Inspect the spindle bore for burrs. Remove any burrs using straight die grinder with light grade flapper

sanding wheel. Clean the bore of any grinding debris.

Check inside spindle to verify that the axle is hollow, which is required for airline passage.

Cover bearings and axle nut with clean towel to prevent contamination.