STEMCO Qwik Kit King Pin Repairs User Manual

No ream installation, For king pin steering knuckle repairs, Getting help

REMOVAL

• Use established procedures for teardown. It is not

necessary to remove the steering knuckle from the truck

to install a STEMCO Kaiser QWIK KIT™.

STEERING KNUCKLE AND AXLE

PREPARATION

• Clean spindle bores and axle eyes then wipe dry.

• Remove any burrs from spindle bores and axle eyes

using a brake hone or similar device.

INSTALLING BUSHING LIP SEALS

• Handle with care, lip seals are easily damaged.

• Using a bushing driver or similar device, drive the seal

into the bore, leaving the seal flush with the axle side

of each spindle.

• Be sure to position the seal so the lip is pointing

towards the axle eye. (see figure #3)

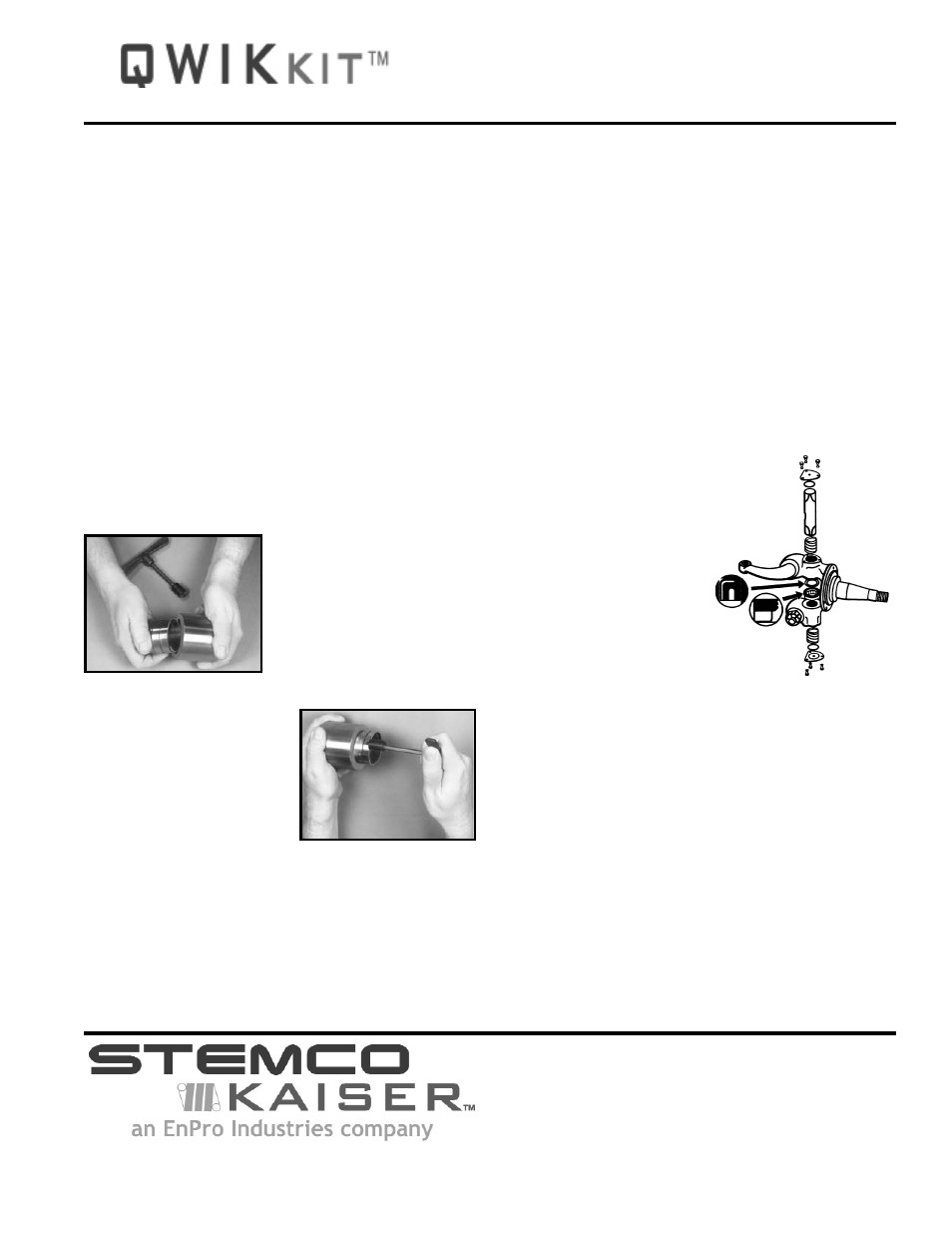

INSTALLING SPIRAL STEEL BUSHINGS

• Place the tip of the bushing

at a slight angle to the bore.

With a push-in, clockwise

twisting action, the bushing

will enter the bore. Continue

with the twisting action as

far as the hand grip will

permit. (see figure #1)

• Grip bushing wall with a "T"

wrench or pliers about 1"

from the tip. Continue the

clockwise rotation as far as

possible. (see figure #2)

• Tap bushing into the bore

until slightly below flush

using a brass mallet.

CHECK BEFORE ASSEMBLY

• Wipe the bushing clean. Insert the king pin into just the

upper bushing, then into just the bottom bushing. In

both cases the pin should be a slip fit. Then insert the

pin into both bushings simultaneously and again the

pin should be a slip fit. If at any time during this test the

pin becomes tight, remove the bushing or bushings

and use a brake hone to thoroughly clean the bores

again. If upon reinstallation the pin is still tight, call

technical service.

BEARING INSTALLATION

• Pre-pack bearing with grease.

• Opening on bearings outside diameter should point

down. (see figure #3)

• Place needed shims under upper spindle bore.

• Position king pin through upper bushing and through

needed shims. Be sure TOP on pin is parallel to axle for

proper lock flat alignment.

• Place spindle, shims and pin onto axle, allow pin into

axle bore about 2".

• Tap bearing into place. A properly fit

bearing will require a slight tap fit with

out damaging the bearing case.

• If bearing is too tight or too loose, adjust

number of shims being used.

•Once bearing fit

is correct allow

pin to slip into

lower bushing.

• Position lock flats on pin so

they line up with lock holes.

• Pound lock pins into place, for lock

pins with threads apply 25-30 ft. lbs of torque

END PLATE OR END PLUG INSTALLATION

• Install end plates or end plugs, use proper seal under

plates

• Install grease fitting into end plate or end plug

GREASING

• Apply grease until it can be seen between axle and

spindle. Then turn spindle and grease again repeating

the process 5 times

CHECK INSTALLATION

• Once greased the spindle should turn easily from side

to side.

• There should be very little up and down movement.

NO REAM INSTALLATION

for KING PIN STEERING KNUCKLE REPAIRS

01 577 0039

FEB 2010

GETTING HELP

USE THE STEMCO Kaiser TECHNICAL SERVICE LINE

888-854-6474

WARNING: STRIKING STEEL PARTS WITH HAMMERS CAN RESULT IN CHIP PROJECTILES, ALWAYS WEAR SAFETY GLASSES TO PROTECT YOURSELF AGAINST

INJURY. STEMCO Kaiser IS NOT RESPONSIBLE FOR ANY INJURY THAT MAY OCCUR DURING THIS PROCESS.

4641 Industrial Drive, Millington, MI 48746 • 888-854-6474 • Fax: 989-871-4640 www.stemcokaiser.com

figure #1

figure #2

Cross section

of bushing lip

seal.

Seal is placed

on top of

thrust bearing.

figure #3