STEMCO Single Tire AirBat RF User Manual

Installation instructions for the airbat, Rf single tire airbat

1

2

3

4

English – Single Tire AirBAT Sensor Installation

WARNING!

Always use appropriate personal protective equipment (PPE)

during the installation and maintenance of the sensors and or related systems

on a vehicle. If you have questions regarding which PPE are appropriate, please

consult

osha 3151-12r 2003 to determine appropriate equipment.

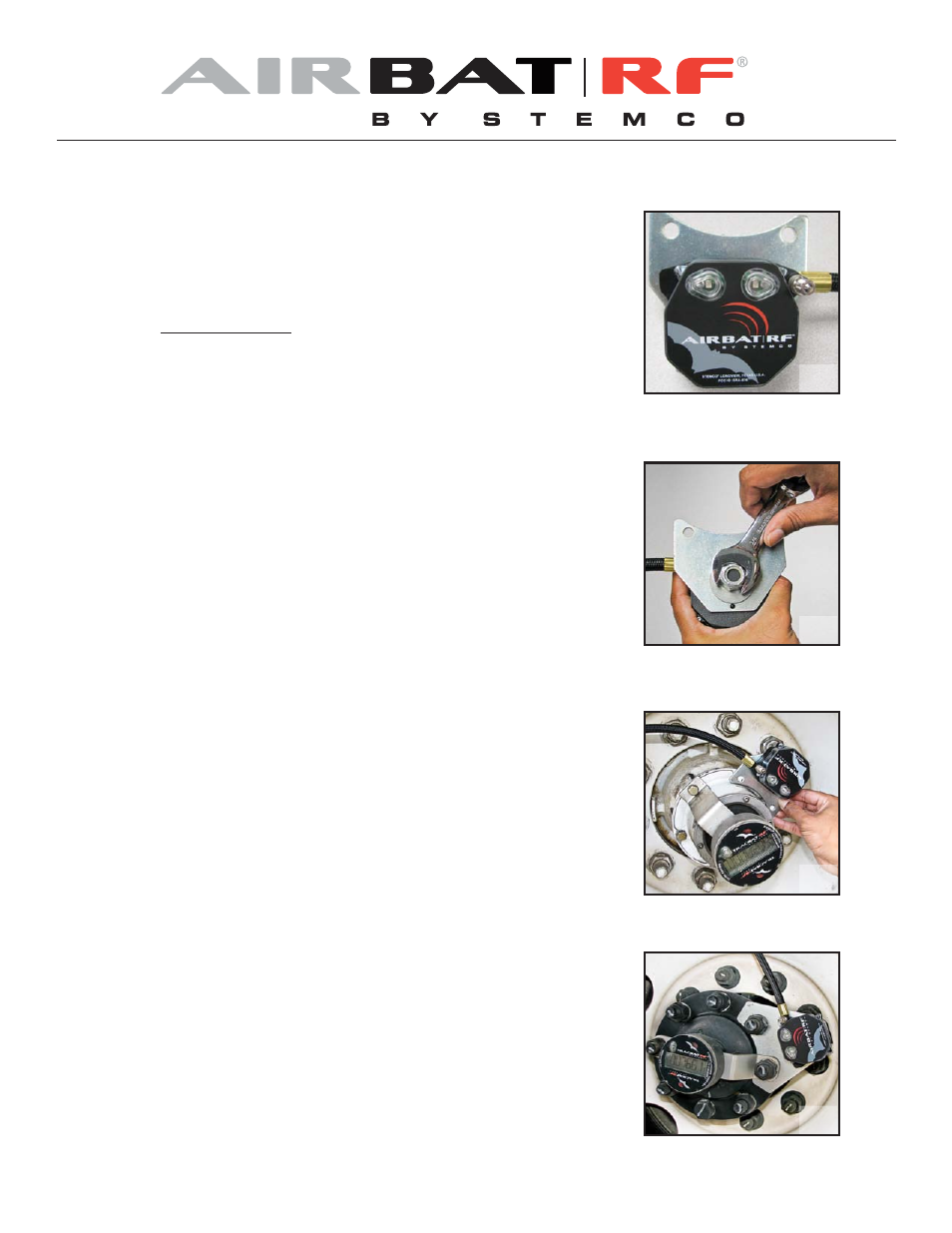

1. Choose the correct bracket for the application. Brackets are available for

drive axles and various trailer hub configurations.

Figure 1

shows a hub cap

flange mounted bracket.

2. Attach the AirBAT to the bracket. The AirBAT has an anti-rotation pin on the

back of the manifold that must fit into the small hole in the bracket. Use

the washer and locking nut supplied with the AirBAT.

CAUTION: USING

HAND TOOLS ONLY, TORQUE THE NUT TO 12 ft-lb. Over-

tightening may break off the mounting stud.

See Figure 2.

3. Make a note of the unique serial number printed on the AirBAT cover. Also

note the position on the truck where the AirBAT is being installed (Left-Rear,

Right-Rear, etc.) along with the vehicle ID. This information may be entered

into WebBAT or used for reference at a later time.

4. Hold the bracket (with AirBAT attached) near the hub and visually select a

pair of mounting studs or bolts on the hub so that the AirBAT hose will not

be stretched or be too loose, as shown in

Figure 3.

Remove the two bolts

and attach the bracket, using the same bolts. Typical hub cap bolts are

5/16 –18 and are tightened 12–16 ft-lb. of torque.

5.

Figure 4

shows the AirBAT attached to a drive axle cover plate. The same

procedure as detailed in step 4 is to be used. Typical drive axle cover plate

nuts are torqued to 250 ft-lb. of torque.

6. Remove any valve stem caps from the wheels. Be sure the threads on the

valve stem are clean and usable with no dings or dents on the sealing edge

of the valve stem. Restore/replace if needed. Connect the AirBAT hose to

the appropriate valve stem and tighten the knurled valve stem fitting to

approximately ½ turn past finger tight. Hand tighten manifold hose fitting

until it is secure and will tighten no further. Use a leak detection method

such as soap and water or a commercial bubble solution to ensure no air

leaks are present.

7. Check the tire pressure with the HandBAT reader or a conventional

tire gauge. The tire may be filled using the fill port on the AirBAT hose

fitting. The HandBAT reading should confirm the unit’s serial number

recorded in step 3.

Installation Instructions for the AirBAT

®

RF Single Tire AirBAT