SDC 1580 SERIES EMLOCK User Manual

Security door controls

Security Door Controls

801 Avenida Acaso, Camarillo, CA 93012 • (805) 494-0622 • Fax: (805) 494-8861

www.sdcsecurity.com • E-mail: [email protected]

The 1500 Series Emlock is mounted to the underside of the header, on

the stop side of the door. A TJ mounting kit (optional) can be used

when mounting on the hinge side of the door. (Fig. 1D)

The armature is mounted to the door. A hardware kit is provided to

compensate for misalignment and wear of the door, by allowing the

armature to pivot on it’s center point.

INSTALLATION INSTRUCTIONS

SERIES 1510, 1570, 1580 EMLOCK

R

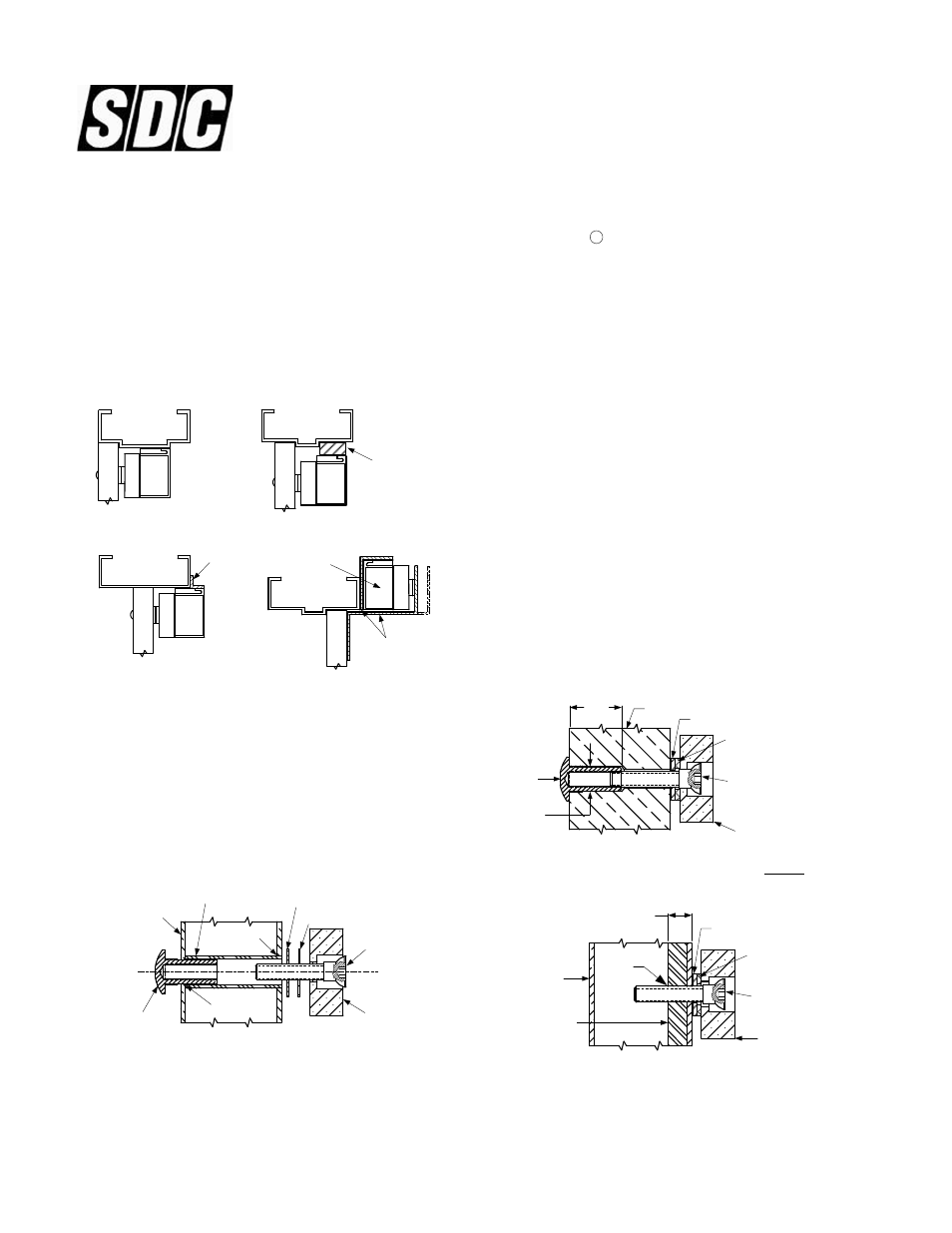

1. Inspect the frame header to determine if an angle bracket or filler plate

is required. See Figure 1A, 1B, 1C.

FIG. 1A

Regular

FIG. 1B

With Filler Plate

FIG. 1C

With Angle Bracket

FIG. 1D

Top Jamb Installation

Adjustable

TJ Bracket

Filler Plate

Angle

Bracket

Standard

Lock

2. Fold template as indicated by dotted line. For single doors, locate

template against the door and header on the lock jamb side of the

frame.

3. Mark and drill holes as indicated bt template. For armature plate hole

preparation, see Figure 2A, 2B, 2C.

4. Mount armature to door. To determine proper hardware (provided), see

Figure 2A, 2B, 2C.

5. Install mounting plate to header with the interlock detail away from the

door side of the stop, with #10 Flt Hd. Screws provided.

FIG. 2A HOLLOW METAL DOOR

From Sexnut side of door, drill exactly 1/2” hole thru one metal thickness

only. From Armature side of door, drill 5/8” hole to insert reinforcement

tube. Press in sexnut and reinforcement tube all the way and mount

armature to door using hardware provided per Figure 2B.

6. Holding the magnet housing at each end, engage the entire

length of the interlock detail, by pushing towards the door.

(If necessary, tap with a soft hammer to ensure proper alignment

and engagement).

Caution: The lock body must be held in place until

secured with mounting screws. Screws provided inside the

housing at each end. Tighten the screws and check alignment.

7. Test operation. When all is operating properly, tighten all

screws. Install anti-tamper plugs over socket head screw

using a soft hammer to avoid damage to the housing.

Electromagnet and armature should be handled carefully.

Any damage to the surface such as paint, burrs, dirt and rust

may hinder bonding of surface and reduce holding power.

SHOULD THE SURFACE PLATING BE DAMAGED:

Do not touch the lock face with your hands.

Using a soft, clean, dry cloth or abrasive cloth (i.e., Scotch-Brite),

clean lock face. Do not use sand paper.

A rust inhibitor such as M1, manufactured by Starret, or LPS3,

manufactured by LPS Laboratories (available at most hardware

stores) can then be applied.

Apply a coat of inhibitor to armature face also.

FIG. 2B SOLID DOOR

Drill 3/8” hole thru door. From sexnut side of door, drill exactly 1/2” hole,

1-3/8” deep. Mount armature to door with hardware provided per Figure 2A.

FIG. 2C REINFORCED DOOR

Drill and tap for 5/16-18 machine screw. Mount

armature to door with hardware provided per Figure 2C.

P:\INSTALLATION INST\Electromagnetic Locks\INST-1500-10-70-80.vsd REV E 04-06 Page 1

ARMATURE

RUBBER

WASHER

WASHER

DOOR

1-3/8“

SEXNUT

1/2“

5/16-18 SOC HD

SCREW

WITH 3/16 (5MM)

ALLEN HEX

REINFORCEMENT

TUBE

1-3/4“ HOLLOW

METAL DOOR

5/8“ DRILL

STEEL WASHER

RUBBER WASHER

5/16-18 SOC HD

SCREW

WITH 3/16 (5MM)

ALLEN HEX

ARMATURE

1/2” DRILL

SEXNUT

ARMATURE

RUBBER

WASHER

WASHER

Add as required

5/16-18

3/8“ MIN

METAL

Reinforcement

by others

DOOR

5/16-18 SOC HD

SCREW

WITH 3/16 (5MM)

ALLEN HEX

Any suggestions or comments to this instruction or

product are welcome. Please contact us through

our website or email [email protected]