SDC 7500 SERIES HiTower Z, S, I, D, P & T User Manual

Security door controls

SECURITY DOOR CONTROLS

801 Avenida Acaso, Camarillo, Ca. 93012 • (805) 494-0622 • Fax: (805) 494-8861

www.sdcsecurity.com • E-mail: [email protected]

P:\INSTALLATION INST\Electrified Lockset\INST-Z7500.vsd REV E 01-13 Page 1

Any suggestions or comments to this instruction or

product are welcome. Please contact us through

our website or email [email protected]

For the door portion follow the enclosed mortise lock instruc-

tions.

For the frame portion (electric actuator) read these instructions

carefully.

To insure a neat and easy installation of the electric actuator into the

frame back box when making long wire runs, the heavier gauge wire

can be terminated in a junction box above the door. At this point a

smaller gauge wire cable may be run from the junction box to the

frame electrical black box. This provides for easier insertion of the

electric actuator.

For proper operation the voltage as indicated on the lock solenoid

must be at the lock location with the load on.

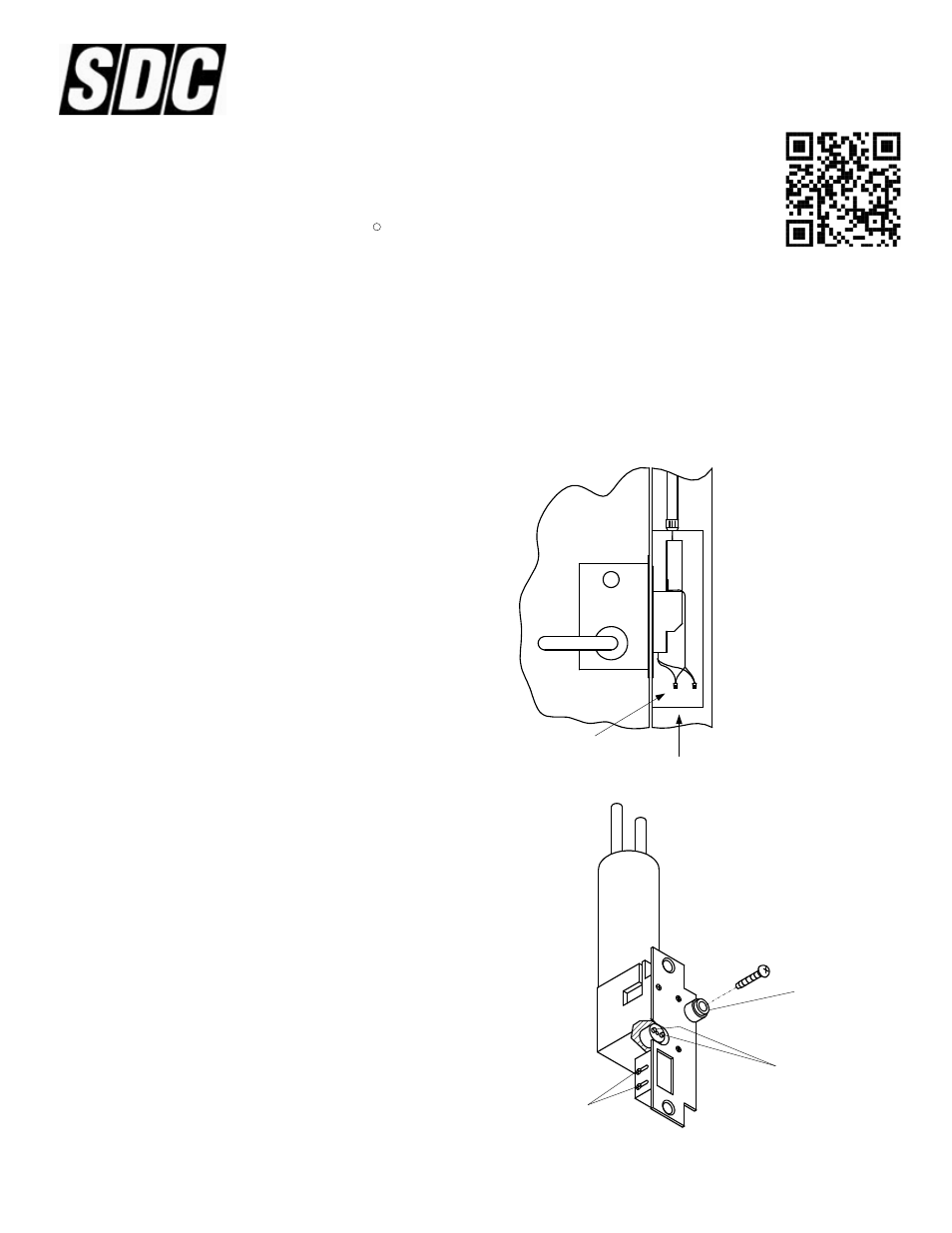

1. Latch position sensor adjustment is set for 1/8” door clear-

ance and is adjustable for wide and narrow door gaps. Make

this adjustment before installing.

To make adjustment please follow steps A, B & C. Refer to

Fig. E.

A. Loosen the two screws on the side of the dust box.

B. Move the switch assembly forward or back to desired position.

Example: For 3/16” door gap move the switch assembly for-

ward 1/16”.

C. Tighten screws.

2. The wiring assignments are shown on the reverse side of this

page as well as on the electric actuator. The lock is supplied with

6" wire leads and will require 10" leads from the conduit.

3. Attach power supply leads to lock leads as shown. Wire nuts are

sufficient for these connections.

4. Insert wires into the jamb carefully so they do not interfere with

proper positioning of the lock in the cut-out.

5. Insert lock and secure with screws provided.

6. With the power on to the electric actuator, check to see if the

levers are locked. On 7540 and 7550 models only the outside

lever should lock. The actuator is set for 1/8” door clearance as

shipped from the factory. If the clearance between the door and

jamb is more or less than 1/8” the following adjustment must be

made (refer to Fig. E).

A. Loosen the allen screw in the plunger.

B. Remove plunger head.

C. Turn each adjustment screw equally in desired direction.

Counter-clockwise for wide gaps – clockwise for narrow gaps.

IMPORTANT: ADJUSTMENT SCREWS MUST BE TURNED

EQUALLY TO OPERATE FREELY.

D. Replace plunger head and test lock. Lever should lock

when actuator is energized.

Strike Plate Dimensions

For Metal Frames: 4-7/8” x 1-1/4” x .0937" Standard ANSI

For pairs of wood doors or wood frames: 9-1/2” X 1-1/4” x 1/8”

For narrow metal frames: 8-1/2” x 1-1/4” x 1/8”

ID Requirements

Standard Actuator: 12" x 2-1/2” x 1-3/4”

Narrow Backset Actuator: 12" x 2-1/2” x 1-1/4”

Fail Safe: Continuous duty – locked when energized

UL Listed: Electrically controlled single point locks or latches

FIG. E

Electric Actuator.

Solenoid points up

when actuator is used

with:

SOURCE

Z SDC

S SCHLAGE

I CORBIN/

RUSSWIN

D SARGENT

P YALE

T BEST

MODEL

7550

L9080

ML2057

8200

8805

45H

DOOR

ELECTRICAL

BACK BOX

FRAME

ACTUATOR

PLUNGER

HEAD

ADJUSTABLE

SCREWS MOVE

OUT FOR WIDE

DOOR GAP

LATCH STATUS

ADJUSTMENT

MOVE FORWARD FOR

WIDE DOOR GAP

INSTALLATION INSTRUCTIONS

HiTower Z, S, I, D, P & T 7500 SERIES

R