Caution – MacDon CA20 Operators Manual User Manual

Page 94

MAINTENANCE/SERVICE

Form 169009

92

Model Year - 2009

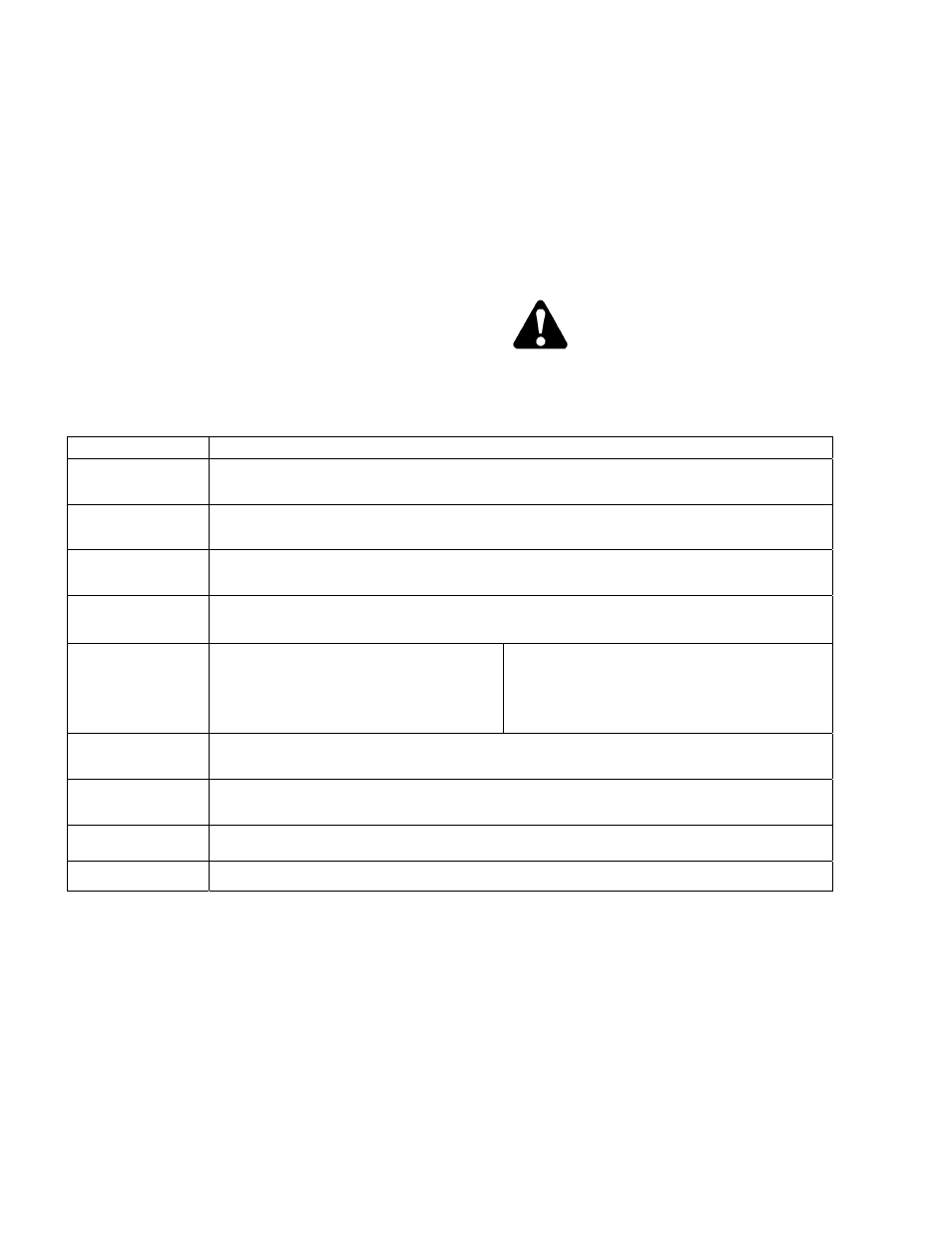

8.13 MAINTENANCE SCHEDULE

The following maintenance schedule is a listing

of periodic maintenance procedures, organized

by service intervals. Regular maintenance is

the best insurance against early wear and

untimely breakdowns. Following this schedule

will increase machine life. For detailed

instructions, refer to the specific headings in

Section 8, Maintenance/Service. Use the fluids

and lubricants specified in Section 8.4, Fluids

and Lubricants.

Service Intervals: The recommended service

intervals are in hours of operation. Where a

service interval is given in more than one time

frame, e.g. "100 hours or Annually", service the

machine at whichever interval is reached first.

IMPORTANT

Recommended intervals are for average

conditions. Service the machine more

often if operated under adverse

conditions (severe dust, extra heavy

loads, etc.).

CAUTION

Carefully follow safety messages given in

Section 8.2 Recommended Safety

Procedures.

INTERVAL SERVICE

FIRST USE

Refer To Section 7.2, BREAK-IN PERIOD.

10 HOURS OR

DAILY

1. Check Hydraulic Hoses And Lines For Leaks.

25 HOURS

1. Check Hydraulic Oil Level at Reservoir.

50 HOURS

1. Grease Drive-line and Drive-line Universals.

2. Grease Draper Roller Bearings.

100 HOURS OR

ANNUALLY *

1. Grease Auger Bearing.

2. Grease Auger Drive Chain.

3. Grease Auger Drive-shaft Bearings.

4. Grease Anti-Vibration Pivots.

5. Grease Float Pivots.

6. Check Auger to Pan and Feed Draper

Clearance.

7. Check Gearbox Lubricant Level.

8. Grease Float Adjust Spring Tensioners.

9. Lubricate

Hydraulic

Couplers.

250 HOURS

1. Change Hydraulic Oil Filter.

2. Grease Auger Pivots.

END OF

SEASON

Refer To Section 7.5, STORAGE.

1500 HOURS OR

3 YEARS

1. Change

Hydraulic

Oil

2. Change Gearbox Lubricant.

* IT IS RECOMMENDED THAT ANNUAL MAINTENANCE BE DONE PRIOR TO START OF OPERATING

SEASON.