MacDon CA20 Operators Manual User Manual

Page 65

OPERATION

Form 169009

63

Model Year - 2009

7.3.6 HEADER

LEVELLING

The adapter is factory set to provide the proper

level for the header and should not normally

require adjustment. If the header is not level,

perform the following checks prior to adjusting

the leveling linkages.

IMPORTANT

The adapter float springs are not used to

level the header.

• Check combine tire pressures.

• Check that combine feeder house is level.

Refer to combine Operator’s Manual.

• Check that top of adapter is level with

combine axle.

Make fine adjustments to header leveling as

follows:

a. Park combine on level ground.

b. Check float lock is disengaged (header can

float).

c. Check and set float adjustment. Refer to

previous section.

d. Set header approximately 6 inches (150 mm)

off ground and check that float linkage is

against down stops. Note high and low end of

header.

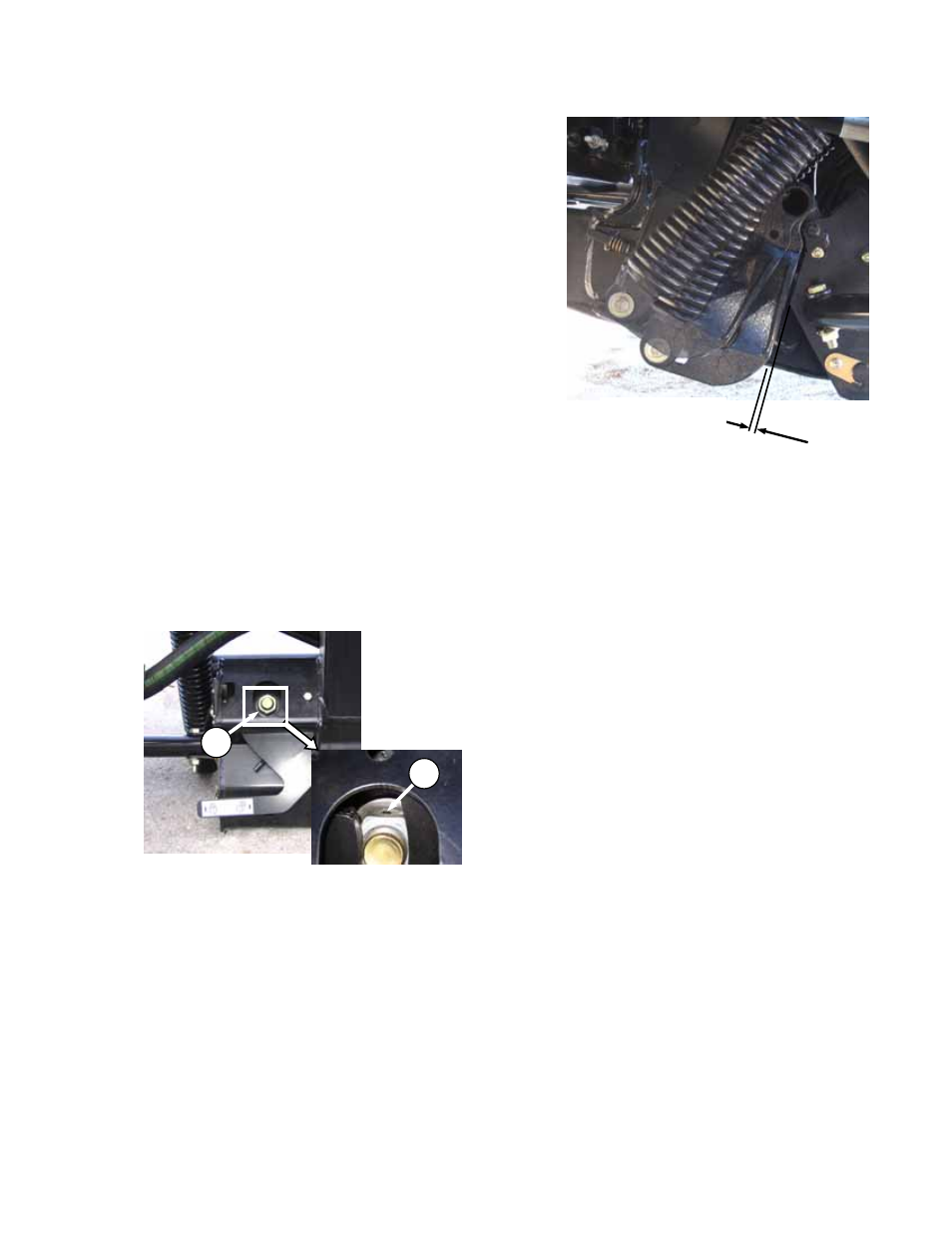

e. Adjust level with nut (A) at each float lock as

follows. Use small adjustments (1/4 -1/2 turn)

and adjust each side equally but in opposite

directions:

NOTE

Set screw (B) does not require loosening

for adjustments up to ½ turn of nut (A).

1. Turn low-side nut clockwise to raise

header.

2. Turn high-side nut counter-clockwise to

lower header.

NOTE

Adjustment of more than two turns in

either direction may adversely affect

header float. Always be sure there is a

minimum 2 to 3 mm (1/8”) clearance

between frame and back of bellcrank

lever as shown.

NOTE

Float does not require adjustment after

levelling header.

A

B

0.12 in. (2-3 mm)

MIN

.