Maintenance – Multiquip WRS5200 (ORIGINAL COPY) User Manual

Page 52

page 52 — wrs5200 hydraulic roller screed • operaTion manual — rev. #0 (10/22/10)

changing hydraulic oil and filters

1. Place the power unit on a clean flat work area and set

the parking brake.

2. Remove the hydraulic oil drain plug and drain

the hydraulic oil. Dispose of the used oil in an

environmentally friendly manner. Replace the drain

plug and tighten.

3. Remove the return filter and install a new filter.

Dispose of the used filter in an environmentally friendly

manner.

4. Disconnect the suction hose and remove the fitting from

the tank. Replace the suction filter. Dispose of the used

filter in an environmentally friendly manner. Replace

the fitting and reconnect the suction hose.

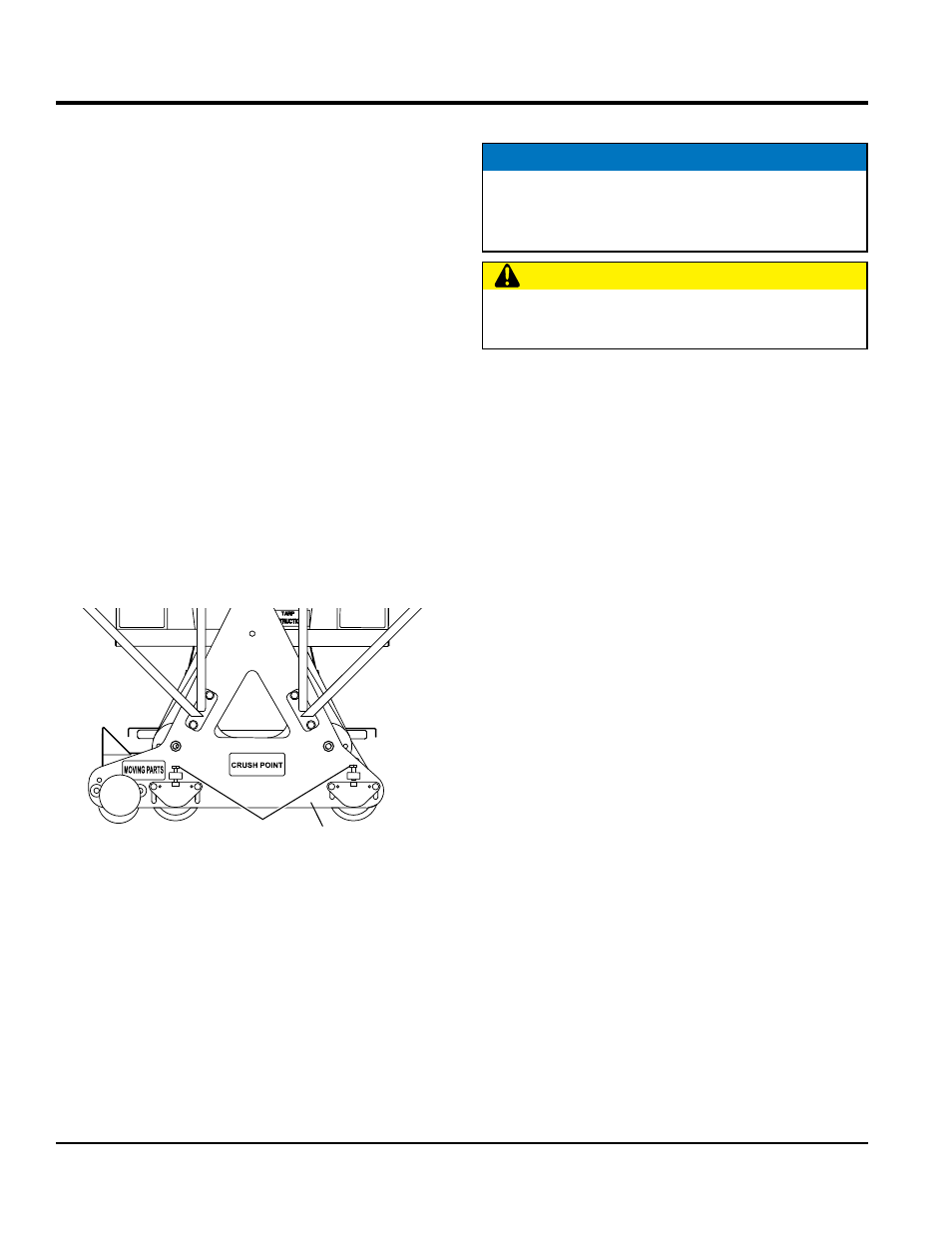

adusTing sTriKe TuBe heighT

Strike tube height is adjusted by raising or lowering the

height of the drive tubes. Figure 47 illustrates this. Loosen

the two bolts which hold each drive tube bearing and adjust

the 3/4" bolt to desired height. Tighten the bearing bolts

Figure 47. Strike Tube Adjustment

OUTER

PLATE

DRIVE TUBE

ADJUSTMENT

Maintenance

engine Tune-up

alTernaTor/regulaTor

The screed is equipped with a 40 amp charging system.

This system uses three charge coils connected in parallel.

The windings of each coil are wound with heave-duty

insulated wire and are further protected by insulating

material for long life. A voltage regulator is provided to

control the amount of charge voltage being delivered to

the 12 volt electrical system. For servicing this charging

system, contact your engine dealer.

NOTICE

See the engine manual supplied with your machine

for appropriate engine maintenance schedule and

troubleshooting guide for problems.

cauTion

always disconnect battery cables before attempting

any service or maintenance on screed.