Roller screed assembly – Multiquip WRS5200 (ORIGINAL COPY) User Manual

Page 45

wrs5200 hydraulic roller screed • operaTion manual — rev. #1 (10/22/10) — page 45

rOller ScreeD aSSeMblY

Task 13: scraper Bars

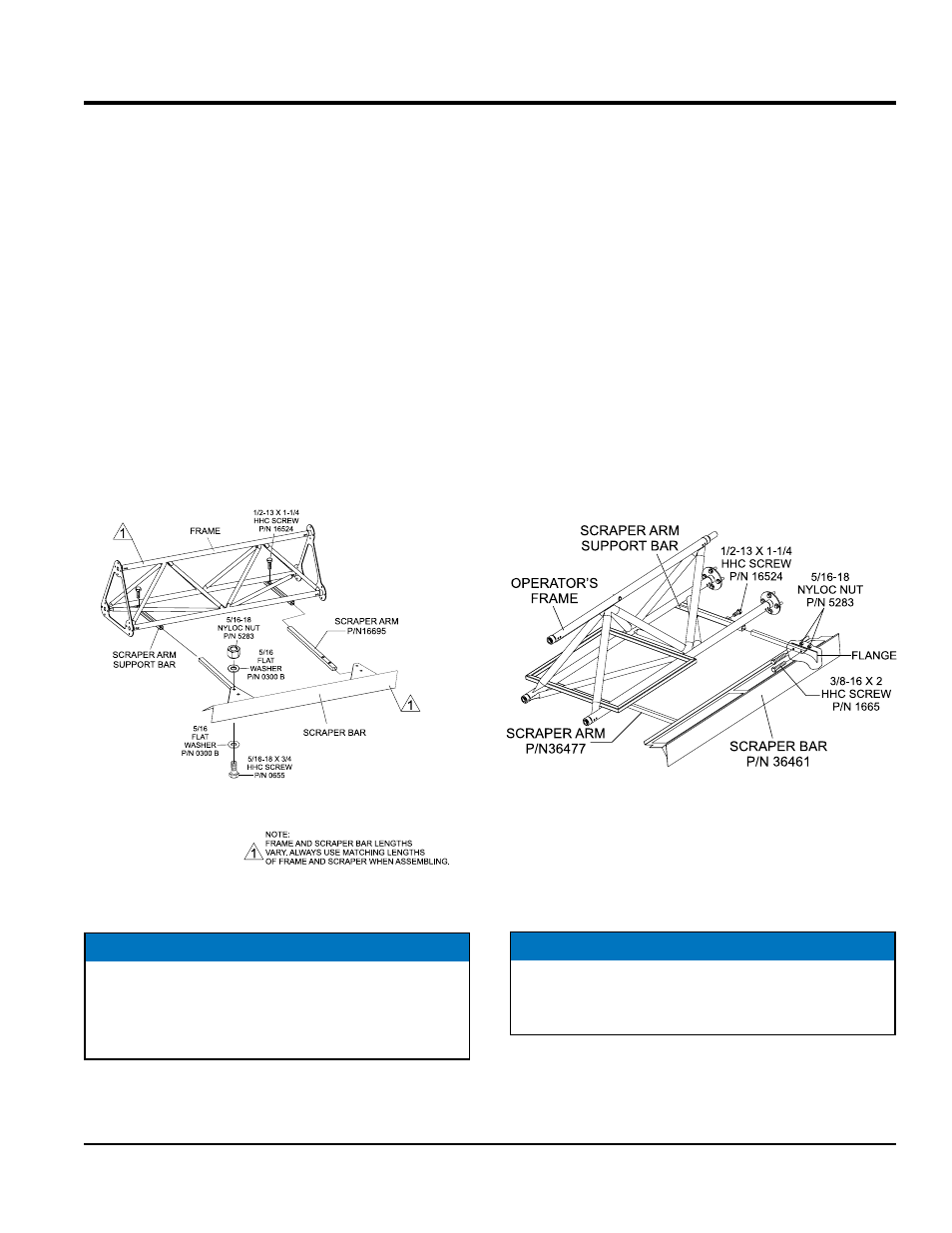

The following instructions illustrate the installation of the

scraper bars onto the

truss sections.

1. Locate scraper bar that matches corresponding section

of truss frame. See Table 9.

2. Next, attach scraper arm (Figure 32) to scraper bar

bar using 5/16-18 X 3/4 screws, 5/16 flat washers and

5/16-18 nyloc nut Tighten securely.

3. Fully insert free end of scraper arm into scrapper arm

support bar that is welded to frame.

4. To hold scraper and scraper arm in place, insert

1/2-13 X 1-1/4 screws into bolt hole opening. Tighten

securely.

5. The scraper bar should be adjusted to 1/8-inch

clearence from the strike tube.

Figure 32. Scraper Bar Installation

(Truss Sections)

NOTICE

Truss frame and scraper bar lengths vary. When

attaching scraper bar to truss frame, ALWAYS make

sure truss frame and scraper bar are of the same length.

Refer to Table 9.

The following instructions illustrate the installation of the

scraper bars onto the

operator and power unit frame

sections.

1. Locate scraper bar that corresponds to the operators

end of frame. See Table 9.

2. Attach scraper arm (side with 2 holes) to scraper flange

as shown in Figure 33, using 3/8-16 X 2 HHC screws

and 5/16-18 nyloc nuts. Tighten securely.

3. Fully insert free end of scraper arm into scrapper arm

support bar that is welded to frame.

4. To hold scraper and scraper arm in place, insert

1/2-13 X 1-1/4 screws into bolt hole opening. Tighten

securely.

5. The scraper bar should be adjusted to 1/8-inch

clearence from the strike tube.

Figure 33. Scraper Bar Installation

Operator's End

6. Attach scraper bar to to power unit fame section in

same maner except use scraper bar P/N 36462.

NOTICE

never let anything rub grooves into the strike tube (i.e.

wiper bars, concrete forms, bolts, etc) because those

groves will be transferred into the concrete.