Maintenance – Multiquip WRS5200 (ORIGINAL COPY) User Manual

Page 51

wrs5200 hydraulic roller screed • operaTion manual — rev. #1 (10/22/10) — page 51

Maintenance

4.

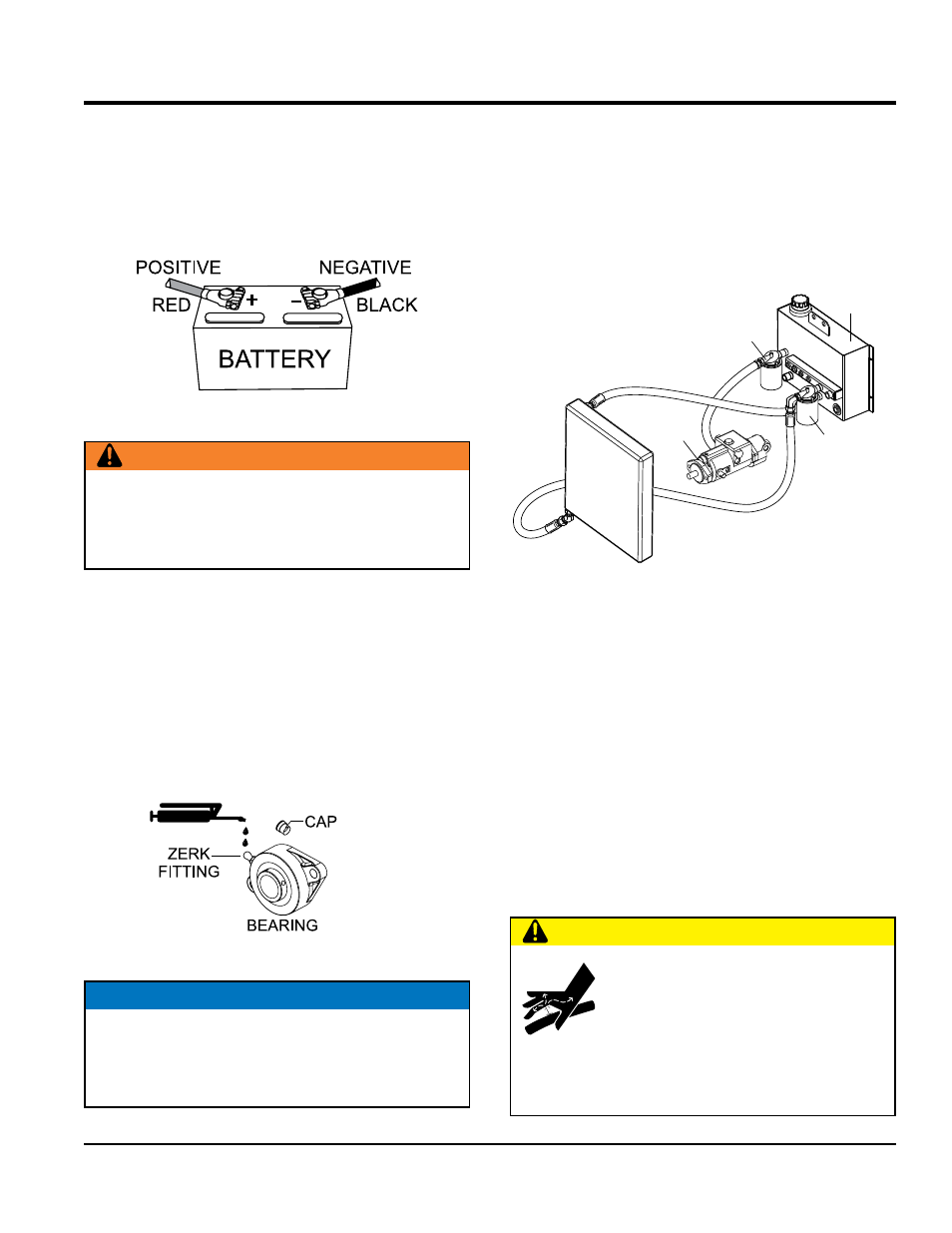

always be sure that the battery cables are properly

connected to the battery terminals as shown below.

Generally the

red cable will be connected to the

positive terminal of the battery, and the

BlacK cable

will be connected to the negative terminal of the battery.

See Figure 44.

Figure 44. Battery

5. Disconnect the negative terminal ( - ) of the battery

during storage. If unit will be stored where ambient

temperature will drop to -15° C or less, remove and

store battery in a warm, dry place.

Bearing luBricaTion

Strike tube and drive tube bearings (Figure 45) require

lubrication daily. Lubricate all bearing zerk grease fittings

with EP3 grease or equivalent.

Figure 45. Zerk Fittings

warning

If the battery cables are connected incorrectly, electrical

damage will occur causing damage to the roller's

electrical circuits. Pay close attention to the polarity of

the battery when connecting the battery.

NOTICE

Failure to lubricate bearing grease fittings daily will

cause rotation of drive and strike tubes to stiffen. To

prevent contamination of the bearing, always insert

cap onto zerk fitting.

hydraulic oil sysTem

The hydraulic system consists of a hydraulic pump directly

coupled to the engine.

Hydraulic oil is filtered by a screen filter located in the tank

filler neck, a 10 micron inlet filter that connects to the hydraulic

tank and pump, and a 10 micron outlet filter that connects

from the cooler to the hydraulic tank. See Figure 46.

Figure 46. Hydraulic Filter Locations

It is recommended that ISO 46 type hydraulic oil or equivalent

be used when adding or replacing the hydraulic oil.

do noT use mulTi-viscosiTy oil. Cleanliness is a

very important part of proper hydraulic system operation.

Hydraulic oil is not only used to transfer power; it also

lubricates and cools the system components. Keeping the

hydraulic system clean can help reduce costly repairs.

The hydraulic oil level sight glass is located on the side of the

hydraulic tank This level should be checked daily. Oil must

be below the top and above the bottom of the sight glass.

do noT overfill! Care should be taken to clean the filler

cap before adding oil to the system. If hydraulic oil has to be

added, the machine should be inspected for leaks.

COOLER

HYDRAULIC

TANK

HYDRAULIC

PUMP

INLET

FILTER

OUTLET

FILTER

cauTion

do noT open hydraulic lines or loosen

hydraulic fittings while engine is running!

Hydraulic fluid under pressure can

penetrate the skin, blind, cause burns

or create other potentially dangerous

hazards follow all safety instructions as described

throughout this manual.