Roller screed assembly – Multiquip WRS5200 (ORIGINAL COPY) User Manual

Page 40

page 40 — wrs5200 hydraulic roller screed • operaTion manual — rev. #0 (10/22/10)

rOller ScreeD aSSeMblY

Task 8: strike Tube motor mounting

For initial setup the strike tube motor can be located on

the power unit (Figure 12, item 9. It is held in place by two

circular support bosses which are welded to the frame of

the power unit.

Remove the pin hitch clip that secures the motor to the

power unit frame and perform the following:

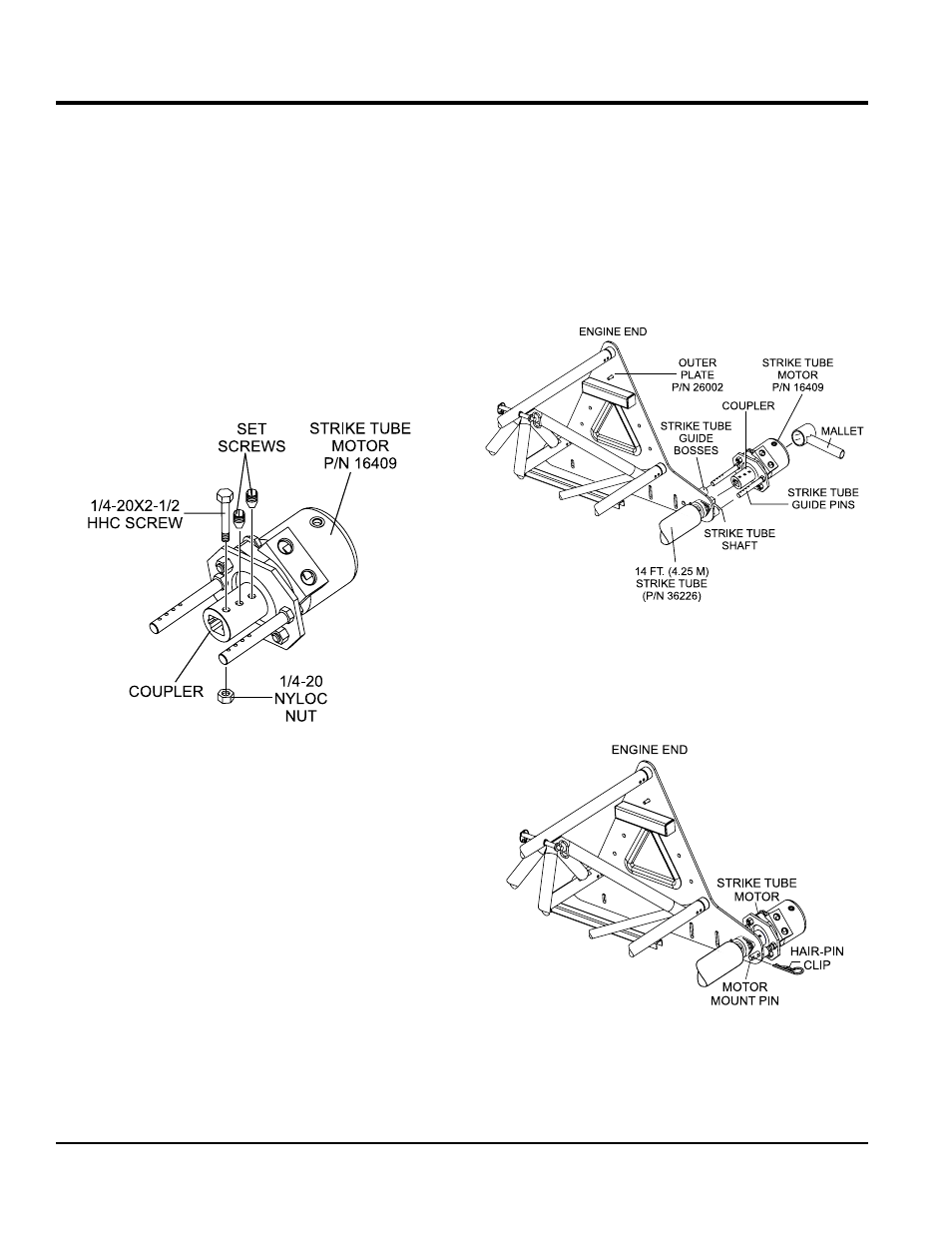

1. Make sure the two set screws (Figure 23) on the

coupler have been retracted enough to allow the

coupler to slide easily onto the strike tube shaft.

2. Second make sure that the shaft retaining screw and

nut have been removed from the coupler.

Figure 23. Strike Tube Motor

3. Insert strike tube motor coupler (Figure 23) onto shaft

of strike tube. Additionally insert strike tube guide pins

into guide bosses located on outer plate.

4. Once coupler and guide pins have been properly

aligned onto strike tube shaft, tap back-end of strike

tube motor with a mallet until first hole on coupler is

aligned with strike tube shaft hole.

5. Using an allen-wrench. Insert both set screws into

coupler. Tighten each set screw securely.

6. To prevent the strike tube from dislodging, insert the

1/4-20X2-1/2 HHC screw into first hole on the coupler

and thru the strike tube shaft. Tap the screw slightly if

necessary.

7. Use a 1/4-20 nyloc nut to secure the screw in place.

Tighten securely.

Figure 24. Securing Strike Tube Motor

8. To prevent the strike tube motor from dislodging, insert

hair-pin clip into strike tube motor mount pin as shown

in Figure 25.

Figure 25. Installing Hair-Pin Clip