Operation – Multiquip WRS5200 (ORIGINAL COPY) User Manual

Page 47

wrs5200 hydraulic roller screed • operaTion manual — rev. #1 (10/22/10) — page 47

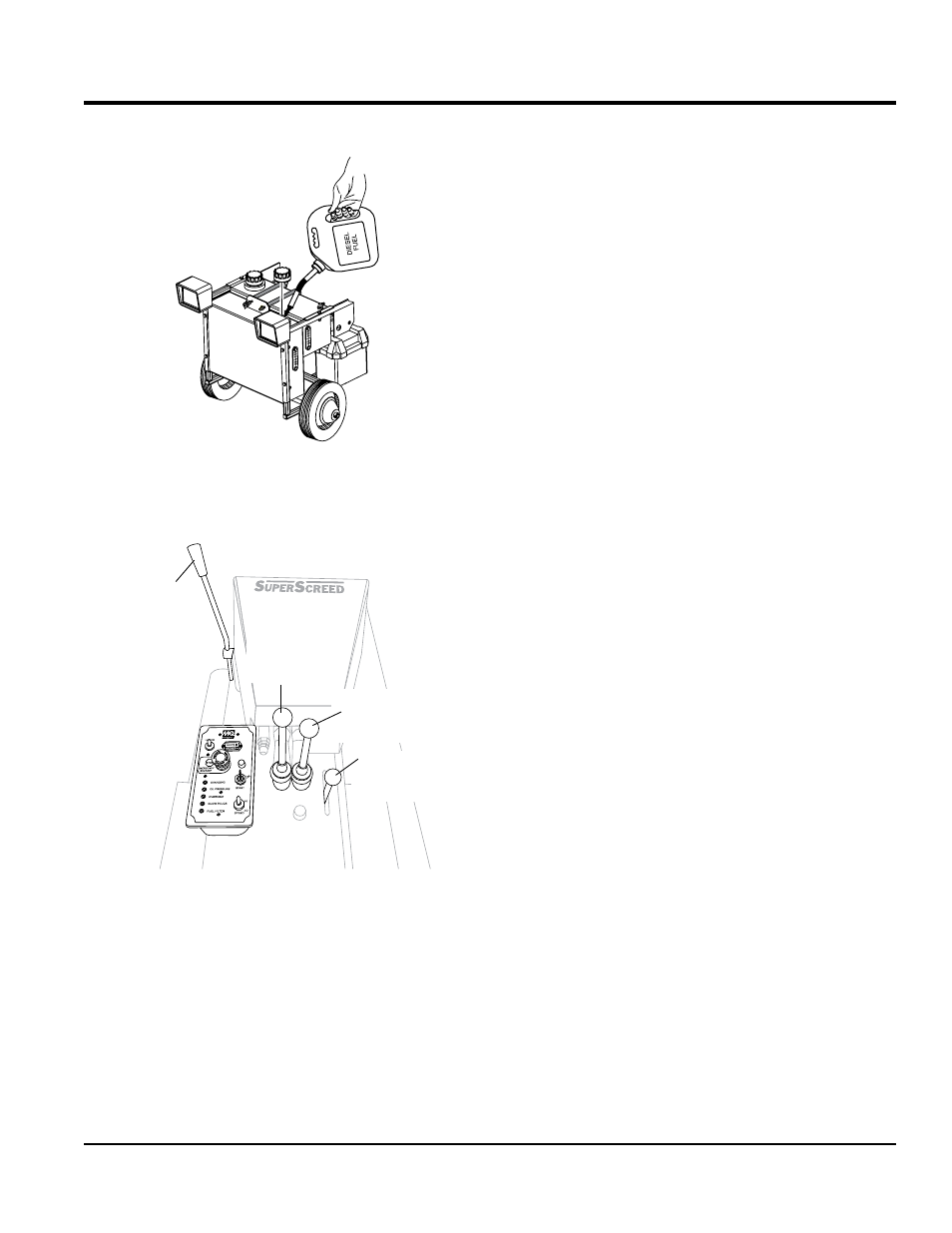

3. If the hydraulic oil level is low, remove the hydraulic oil

cap (Figure 37) and fill with type ISO 46 anti-wear type

hydraulic oil to the recommended operating level.

Figure 37. Adding Hydraulic Oil

sTarTing

Reference Figure 38.

Figure 38. Lever Operation

1. On the power unit place the operation valve lever in the

screed position (See Figure 12, item 12).

2. Sit down in operator's seat and pull safety bar inward

towards your body.

3. Place the two drive tube directional control levers in

the

middle position.

4. Place the drive tube speed control lever in the

straight

up position.

OPERATOR END

DIRECTIONAL

DRIVE TUBE

CONTROL LEVER

ENGINE END

DIRECTIONAL

DRIVE TUBE

CONTROL LEVER

DRIVE TUBE

SPEED CONTROL

LEVER

STRIKE TUBE

SPEED AND

DIRECTIONAL

CONTROL LEVER

OperatiOn

5. Place the strike tube speed and directional control lever

in the

neutral (center) position.

6. Pull upwards on the emergency stop switch.

7. Place engine speed switch in the

LO position.

8. Insert ignition key into ignition switch. Next, turn ignition

key to the

on position. This position allows warming of

the glow plugs.

9. When glow plug status LED goes off, turn ignition key

to start position.

10. Let engine idle for 2 to 3 minutes. Listen for any

abnormal sounds.

11. Verify that all engine status LED's on the control box are

OFF. If any status LED's are on, shutdown the engine

and correct the problem.

12. Place engine speed switch in the

HI position.

operaTion

1. Fully engage the

operator end directional drive tube

control lever in the forward direction.

2. Move the drive tube speed control lever slightly forward

(a few rpm's) and verify that both drive tubes rotate.

3. Fully engage the

operator end directional drive tube

control lever in the reverse (pull back) direction.

4. While drive tube is rotating, push safety bar forward

and verify that drive tube rotation stops.

5. Return operator end directional drive tube control lever

to center position.

6. Move the

power unit end directional drive tube control

lever fully forward and verify that both drive tubes

rotate.

7. Next, fully engage the

power unit end drive tube

control lever in the reverse (pull back) direction and

verify that both drive tubes rotate.

8. Return power unit end directional drive tube control

lever to center position

9. Place the drive tube speed control lever in the

straight

up position (off).

10. Move the strike tube speed and direction control lever

slightly forward. Verify strike tube rotates in a clockwise

rotation. Move lever slightly backwards and verify that

strike tube rotates in a counter-clockwise direction.

11. Screed is now ready for use.