MTS SWIFT 30 Sensor User Manual

Page 84

SWIFT 30 Sensors

84

Test Track Vehicle

Installing the Transducer

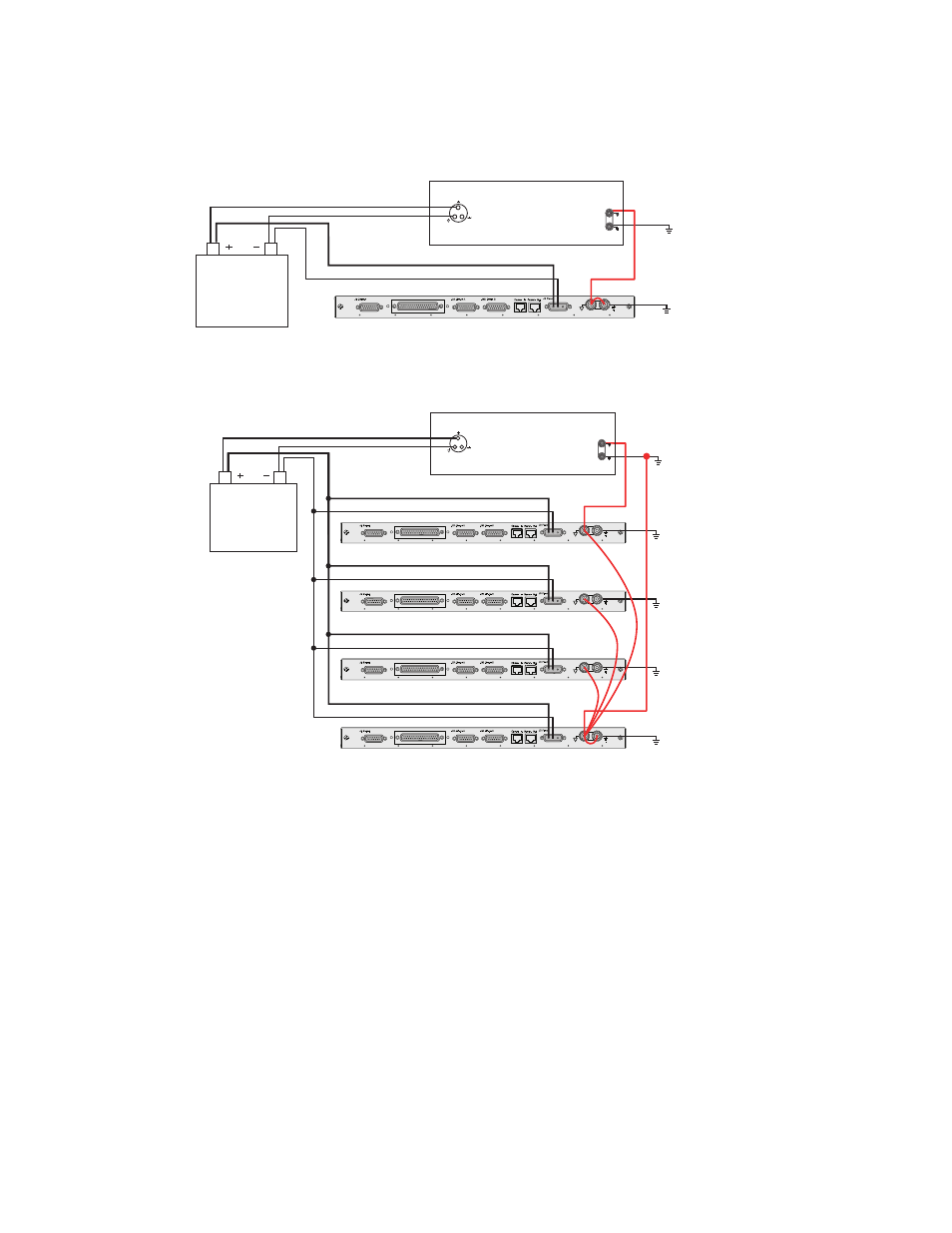

3. Ground the TI and data recorder to the vehicle frame. (See the following

figures.)

Suggested Grounding for a single TI Box

Suggested Grounding for a Multiple TI Boxes

4. Secure the TI box so that it will not move during data collection.

Note

If the TI box is not properly secured, it can bump against another piece of

equipment or a hard surface, pushing in the Zero button. If the Zero

button is pushed, you will lose all of the data.

5. Verify that the shunt contacts are covered.

Make sure that the plugs on the slip ring bracket (spider) cover are in place

so that no water will enter the contacts.

Make sure that the bayonette covers on the shunt connectors are securely

locked in place. Each cover should be twisted until it snaps into the retaining

groove.

6. Turn on the TI and let it warm up for 15-20 minutes before you zero the

strain gage bridges.

Ground to

vehicle frame

12 Vdc

Transducer Interface

S50-025

Data Recorder

Ground to

vehicle frame

12 Vdc

Transducer Interface

Transducer Interface

Transducer Interface

Transducer Interface

S50-026

Data Recorder

- Series 111 Accumulator (40 pages)

- Series 249G2 Swivels (34 pages)

- Series 201 Actuators (40 pages)

- Series 215 Rotary Actuator (68 pages)

- Series 242 Actuators (40 pages)

- Series 244 Actuators (68 pages)

- Series 247 Actuators (40 pages)

- Series 248 Actuators (46 pages)

- 709 Alignment System (158 pages)

- Series 609 Alignment Fixture (70 pages)

- 494 Controller Hardware FT 40 (344 pages)

- ReNew Technical Reference (50 pages)

- DCPD Measurement System (46 pages)

- Bionix EnviroBath (40 pages)

- FGW900 High-temperature Furnace (38 pages)

- Model 409.83 Temperature Controller (40 pages)

- Series 651 Environmental Chambers (30 pages)

- Series 653 High-Temperature Furnaces (38 pages)

- Series 658 Environmental Chamber (24 pages)

- Series FEC Environmental Chamber (48 pages)

- Model 685.53 Grip Control Module (24 pages)

- Series 685 Hydraulic Grip Supply (48 pages)

- Bend Fixture-10 kN (2 pages)

- Grip-Manual Bend Fixture-100 kN (2 pages)

- Grip-Manual Bollard-2 kN (2 pages)

- Grip-Manual Bollard-500 N (2 pages)

- Compression Platen-100 kN-100mm (2 pages)

- Compression Platen-100 kN-150mm (2 pages)

- Compression Platen-100 kN-200mm (2 pages)

- Compression Platen-20 kN (2 pages)

- Compression Platen-20 kN-100mm (2 pages)

- Compression Platen-20 kN-200mm (2 pages)

- Compression Platen-20 kN-SST (2 pages)

- Compression Platen-500 N FYC502A (2 pages)

- Compression Platen-500 N FYB502A (2 pages)

- Compression Platen-500 N-50mm (2 pages)

- Grip-Pneumatic Vise-Style-1 kN (2 pages)

- Pneumatic Bollard-500 N (2 pages)

- Scissor-Style-2 kN (2 pages)

- Scissor-Style-5 kN (2 pages)

- Screw-Style-5 kN (2 pages)

- Screw-Style-5 kN-SST (2 pages)

- Bend Fixture-1000 kN (2 pages)

- Bend Fixture-300 kN (2 pages)

- Bolt Grips (32 pages)