Non-spinning connector housing – MTS SWIFT 30 Sensor User Manual

Page 20

SWIFT 30 Sensors

20

Construction

Hardware Overview

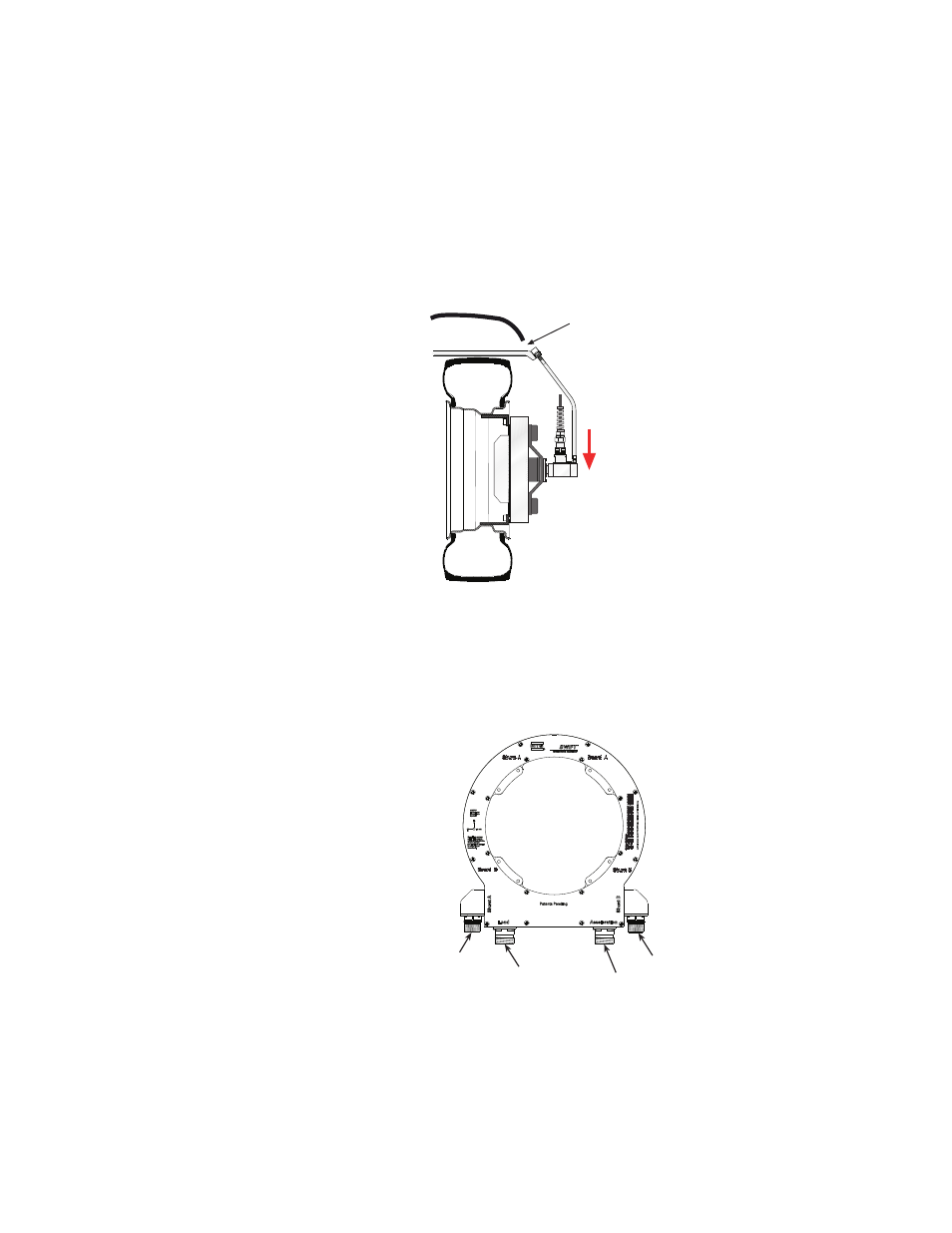

The anti-rotate device should be configured such that no loading occurs to the

slip ring throughout all loading and suspension travel. This means that when you

attach the anti-rotate device to the vehicle, you must consider all possible motion

of the suspension. The anti-rotate device should not bump against the wheel well

at any time; any jarring of the anti-rotate arm will damage the slip ring. For

steering axles, the anti-rotate bracket must be mounted to part of the unsprung

suspension that steers with the tire, such as the brake caliper. For additional anti-

rotate device mounting recommendations, refer to the Anti-Rotate Customer/

User Assembly drawing at the back of this manual.

Non-spinning

connector housing

The non-spinning connector housing or the non-spinning connector bracket (both

shown below) provide a connection between the SWIFT and the TI electronics

for non-spinning use. Both assemblies incorporate rugged connectors suitable for

durability testing. The non-spinning connector housing can also include an

optional connector with built-in, tri-axial accelerometers.

Wheel Well

A jarring motion

will damage the

slip ring

Allow enough clearance

for all loading and

suspension travel

S20-05

Shunt B

Shunt A

Accelerometer

(optional)

Load

S30-25

Connector Housing