MTS SWIFT 30 Sensor User Manual

Page 82

SWIFT 30 Sensors

82

Test Track Vehicle

Installing the Transducer

C. Measure, making bends as necessary, and cut the aluminum tube to

size.

MTS provides an extra long tube with a hinge welded at one end. After

fitting the tube to your test vehicle, cut off the excess length.

D. Tap the end of the aluminum tube 5/16-18 UNC X 1.00 inch deep.

E.

Insert the low-head cap screw through the delrin ball.

F.

Insert the aluminum tube into the steel sleeve.

G.

Tighten the screws that attach the hinge joint to the slip ring assembly.

5. Attach the transducer output cable to the slip ring encoder connector and the

Slip Ring D-connector on the rear of the TI.

6. Secure the cable along its length so that ot will not become damaged during

data collection. (For example, tape it to the external mirror.)

Be sure to leave enough slack in the cable to allow for the full range of

wheel travel (jounce and steer).

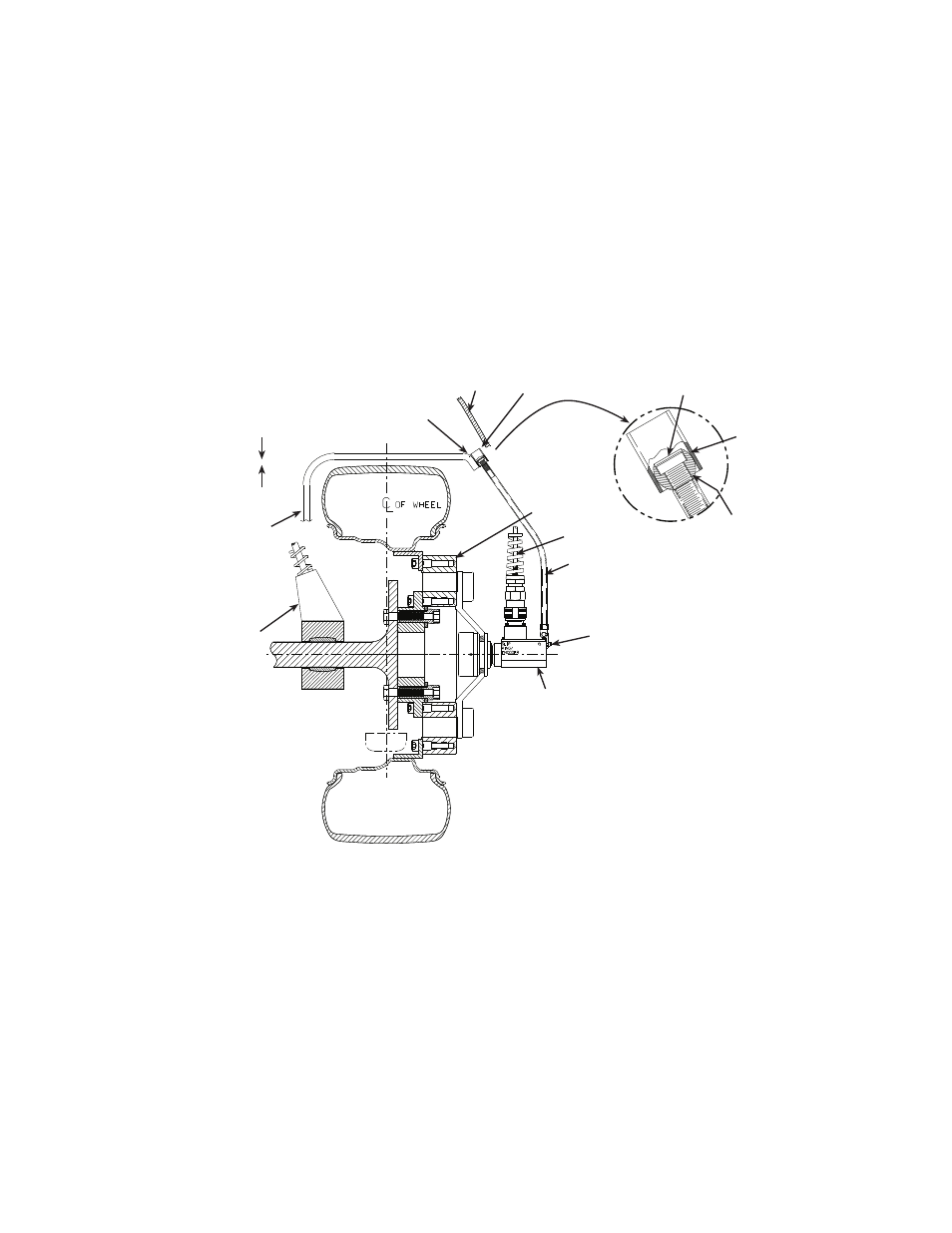

Slip Ring

Assembly

Suspension/

Unsprung Mass

Minimum Clearance

Typically approximately

6 mm (0.25 in) depending

on tire uniformity. Tire

must not hit bracket when

loaded or rotating.

Anti-Rotate Bracket

must be Stiff (preferably steel

or stiff aluminum tubing), so as

not to move or rotate when

connected to unsprung mass

or spindle, which will allow the

slip ring assembly to move with

the tire as the vehicle is

moving or testing.

Center line

of Wheel

Anti-Rotate

Assembly

Transducer

5/16-18 UNC

Low-head Socket Screw

19 mm (0.75 in) long

Steel

Sleeve

Modified Delrin Ball

15.875 mm (0.625 in)

diameter

Vehicle

Fender

Bracket must not hit

fender at extreme end

of suspension travel

Weld steel sleeve to

anti-rotate bracket

when assembly is

mounted on vehicle

S30-18

M4 X 0.7 mm

X10 mm long

or 8-32 X 3/8 in long

Socket Head

Cap Screw (qty 2)

Transducer

Output Cable