Construction, Construction 18, Transducer – MTS SWIFT 30 Sensor User Manual

Page 18

SWIFT 30 Sensors

18

Construction

Hardware Overview

Construction

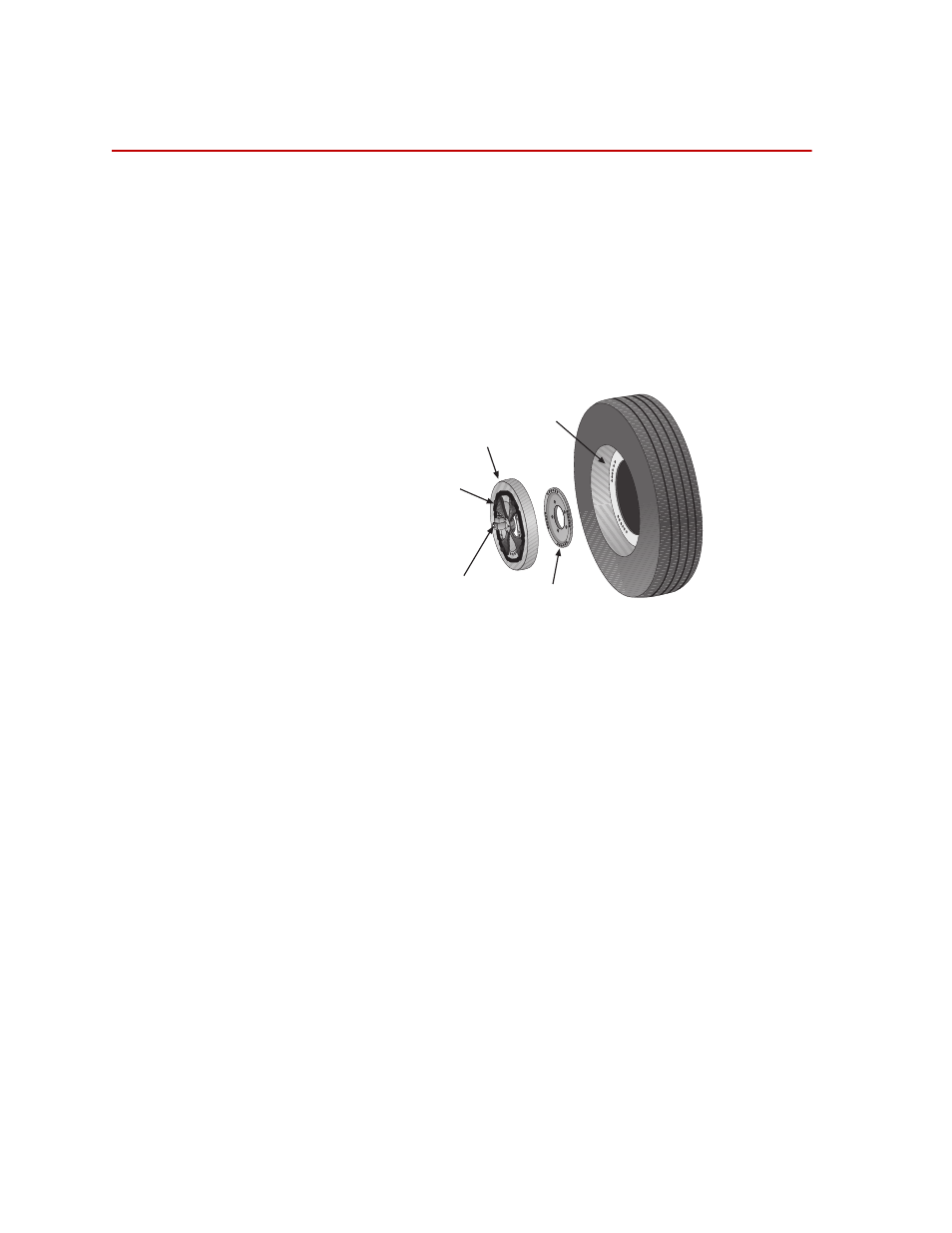

The SWIFT sensor has one-piece construction for outstanding fatigue life, low

hysteresis, and high stiffness. Its compact package has a minimal effect on inertia

calculations, and a minimal dynamic effect on the test vehicle.

The transducer can be used for developing conventional durability tests on the

MTS Model 329 Road Simulator. Normally, the transducer is replaced with an

equivalent wheel adapter after the simulation drive signals are developed and

prior to the start of the test.

The SWIFT sensor includes several mechanical and electrical components.

Transducer

The transducer attaches directly to a modified wheel rim. On the test track, it

spins with the wheel. It does not spin on a road simulator. The transducer is

available in two materials: aluminum for spinning applications where the priority

is on light weight, and titanium for non-spinning applications, where the priority

is on durability.

The transducer’s unibody design means there are no multiple parts welded or

screwed together.

The transducer has four beams with strain gages that measure six orthogonal

outputs:

Fx—longitudinal force

Fy—lateral force

Fz—vertical force

Mx—overturning moment

My—acceleration and brake torque

Mz—steering moment

It has onboard conditioning and amplifiers to improve the signal-to-noise ratio.

S20-03

Transducer

Hub Adapter

Slip Ring

(with Encoder)

Modified

Wheel Rim

Slip Ring

Bracket

(Spider)