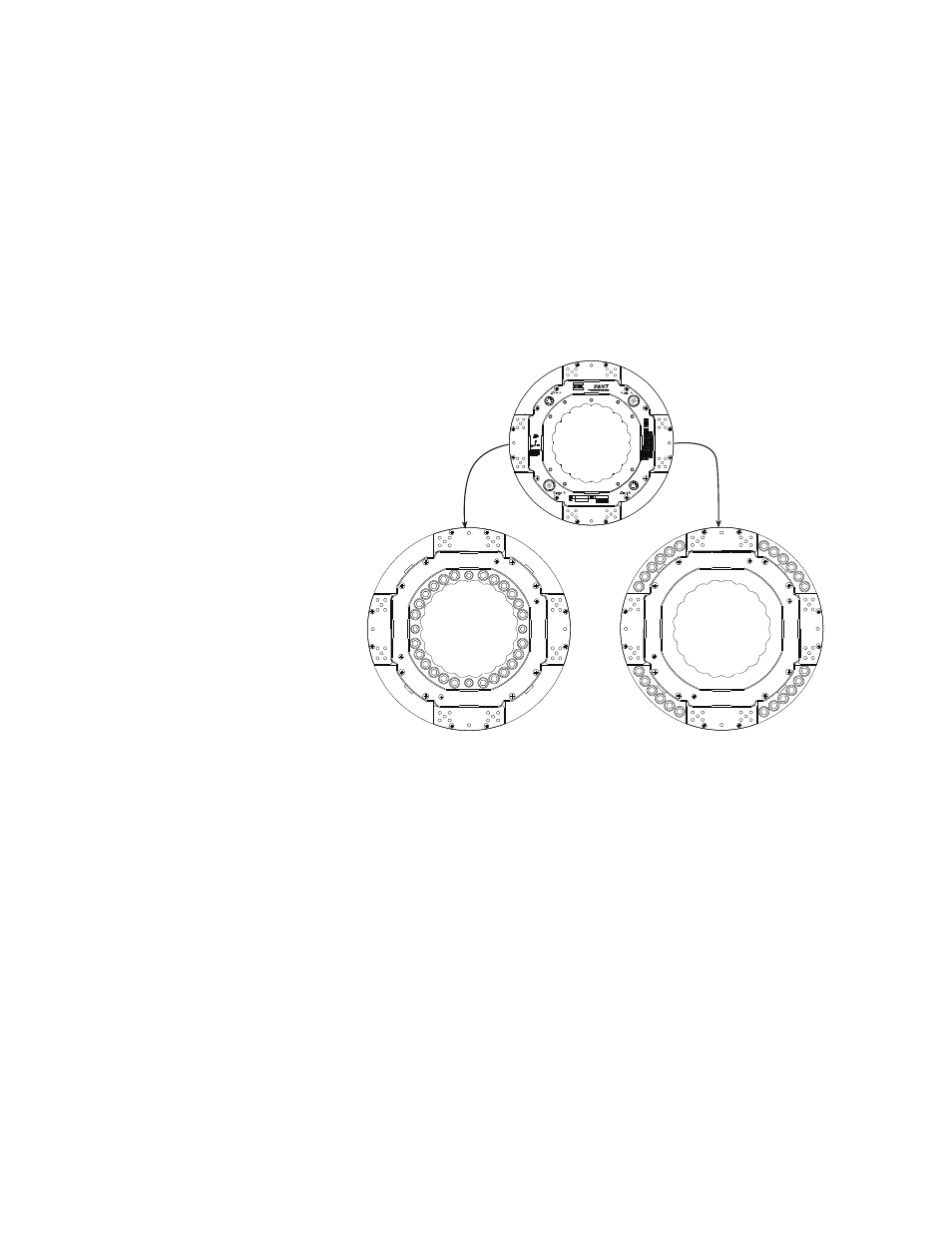

Swift 30a or swift 30t viewed from pilot side – MTS SWIFT 30 Sensor User Manual

Page 79

Test Track Vehicle

SWIFT 30 Sensors

Installing the Transducer

79

5. Attach the hub adapter to the transducer. Hand tighten the bolts.

If environmental conditions warrant, coat each fastener with Birchwood

Casey Sheath RB1 rust preventative (or equivalent).

Lubricate the threads and under the heads of all fasteners, using Molykote

g-n paste.

A clearance of approximately 0.05 mm (0.002 in) is required between the

transducer and the hub adapter. You should not have to wedge the wheel into

the rim or the hub adapter into the SWIFT sensor.

Bolt Torque Sequence

6. Tighten the mounting bolts.

A. Following the sequence shown in the previous figure for the transducer

being installed, torque the four M8 inner hub bolts in two increments as

shown in the following table.

Important

The M8 bolts in the inner bolt pattern (bolts A–D in the previous

figure) must be torqued, as described, before torquing the M10

bolts.

B. Following the sequence shown in the previous figure for the transducer

being installed, torque the twenty-four M10 inner hub bolts in two

increments as shown in the following table.

SWIFT 30A or SWIFT 30T

Viewed from Pilot Side

S30-16

Inner Bolt Pattern

Bolts AD are M8

Bolts 124 are M10

Outer Bolt Pattern

All bolts are M10

B

A

8

4

16

11

19

23

14 2

D

6 10

18

22

15

3

7

12

20

24

13

21

17

9 5

C

1

4

16

21

17

9

5

1

13

24

20

12

7

3

15

22

18

10

6

2

14

23

19

11

8