Lenze SCD Series User Manual

Page 45

42

NOTE: If this parameter is changed while the drive is running, the new value will not take effect

until the drive is stopped.

P28

FIXED BOOST

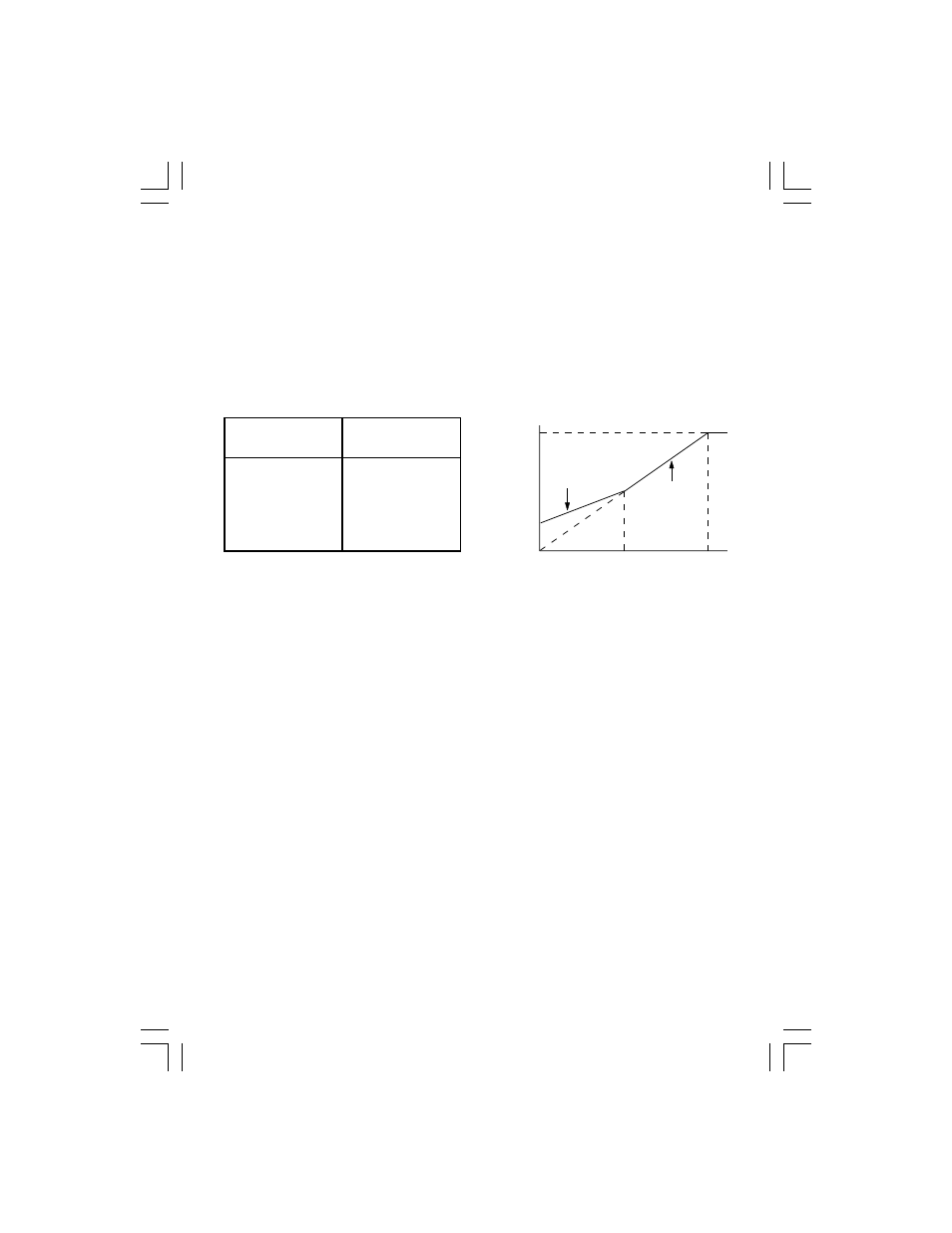

FIXED BOOST increases starting torque by increasing the output voltage when operating below half

of the base frequency, which increases the V/Hz ratio (see diagram below). For better out-of-the-box

performance, SCD Series drives are shipped with a setting that is different from the factory default, as

seen in the table below. If a factory reset is performed, FIXED BOOST will default to 1.0 %.

P29

ACCELERATION BOOST

ACCELERATION BOOST helps accelerate high-inertia loads. During acceleration, the output voltage

is increased to increase motor torque. Once the motor reaches the new speed setpoint, the boost is

turned off and the output voltage returns to the normal value.

P30

SLIP COMPENSATION

SLIP COMPENSATION is used to counteract changes in motor speed (slip) caused by changes in

load. In a standard AC induction motor, the shaft speed decreases as load increases, and increases as

load decreases. By increasing or decreasing the output frequency in response to an increasing or

decreasing load, the slip is counteracted and speed is maintained. Most standard NEMA B motors

have a 3% slip rating.

P31-P37

PRESET SPEED #1 - #7

Preset speeds are activated by contact closures between TB-4 and TB-13A, 13B, and 13C. The TB-

13 terminals must be programmed as preset speed selects using Parameters 10-12.

NOTE 1: Preset speeds can operate below the frequency defined by the minimum frequency parameter

(Parameter 23). The range of adjustment for the preset speeds is from 0 Hz to the maximum frequency

(Parameter 24).

Refer to the table below for activation of the preset speeds using the TB-13 terminals.

"Normal"

Linear V/Hz

Ratio

V/Hz Ratio

Affected By

Fixed Boost

1/2 Base

Frequency

Base

Frequency

Full

Output

Volts

FACTORY

FACTORY

HP

SETTING

HP

SETTING

0.25 - 1

5.3 %

7.5

2.7 %

1.5

4.4 %

10

2.4 %

2

4.4 %

15

2.2 %

3

3.6 %

20

2.0 %

5

3.0 %

25

1.8 %