INFICON BCG450 ATM to Ultra-High Vacuum Triple Gauge User Manual

Page 48

48

tina40e1-b (2011-04)

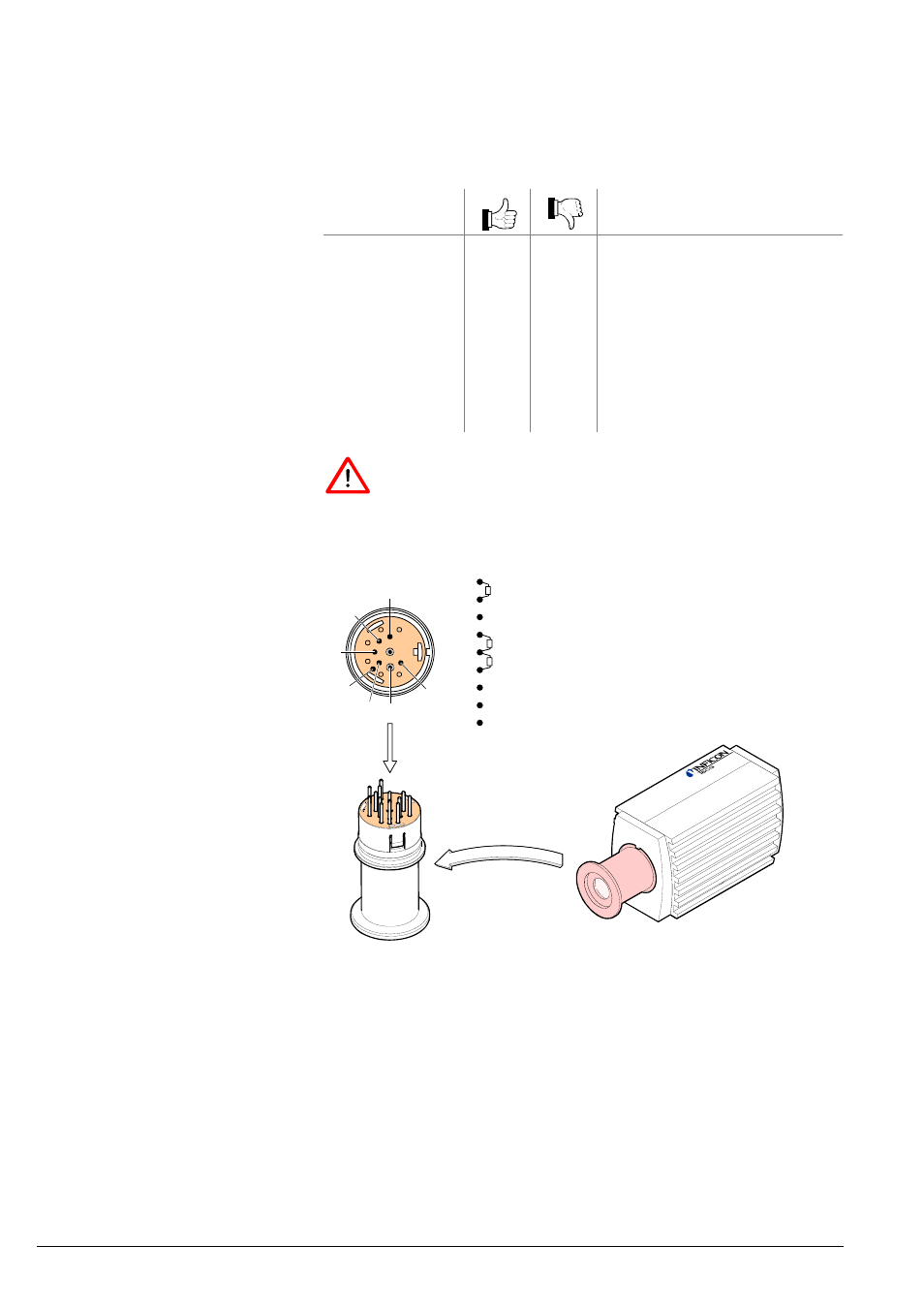

If the cause of a fault is suspected to be in the sensor, the following checks can be

made with an ohmmeter (the vacuum system need not be vented for this purpose).

Separate the sensor from the electronics unit (

→ 15). Using an ohmmeter, make

the following measurements on the contact pins.

Ohmmeter measure-

ment between pins

Possible cause

2 + 4

≈37 Ω >>37

Ω Pirani element 1 broken

4 + 5

≈37 Ω >>37

Ω Pirani element 2 broken

6 + 7

≈0.15 Ω >>0.15

Ω Filament of hot cathode broken

4 + 10

∞ <<∞

Electrode - short circuit to ground

6 + 10

∞ <<

∞

Electrode - short circuit to ground

3 + 10

∞ <<

∞

Electrode - short circuit to ground

9 + 10

∞ <<

∞

Electrode - short circuit to ground

6 + 3

∞ <<

∞

Short circuit between electrodes

9 + 3

∞ <<

∞

Short circuit between electrodes

All unmarked pins in the diagram are used by the diaphragm sensor

electronics and cannot be utilized for diagnostic purposes (do not con-

nect an ohm meter/continuity checker to these pins).

Hot cathode

ca. 0.15 Ohm

Ion collector

Pirani sensor 1

ca. 37 Ohm

Pirani sensor 2

ca. 37 Ohm

6

7

8

2

4

5

3

10

9

Anode

Not connected

GND (connected to sensor housing)

7

2

3

4

5

6

10

View on sensor pins

All of the above faults can only be remedied by replacing the sensor (

→ 49).

Error diagnosis of fieldbus gauges can only be performed as described above for

the basic sensor and sensor electronics. Diagnosis of the fieldbus interface can

only be done via the superset bus controller (

→ [1], [2]).

For diagnosis of the BCG450-SD (DeviceNet) gauges, the status lights might pro-

duce some useful information (

→ 39).

Troubleshooting (sensor)

Correction

Troubleshooting on

Fieldbus Gauges

(BCG450-SD, -SP)