Enerpac E-Series User Manual

Page 3

3

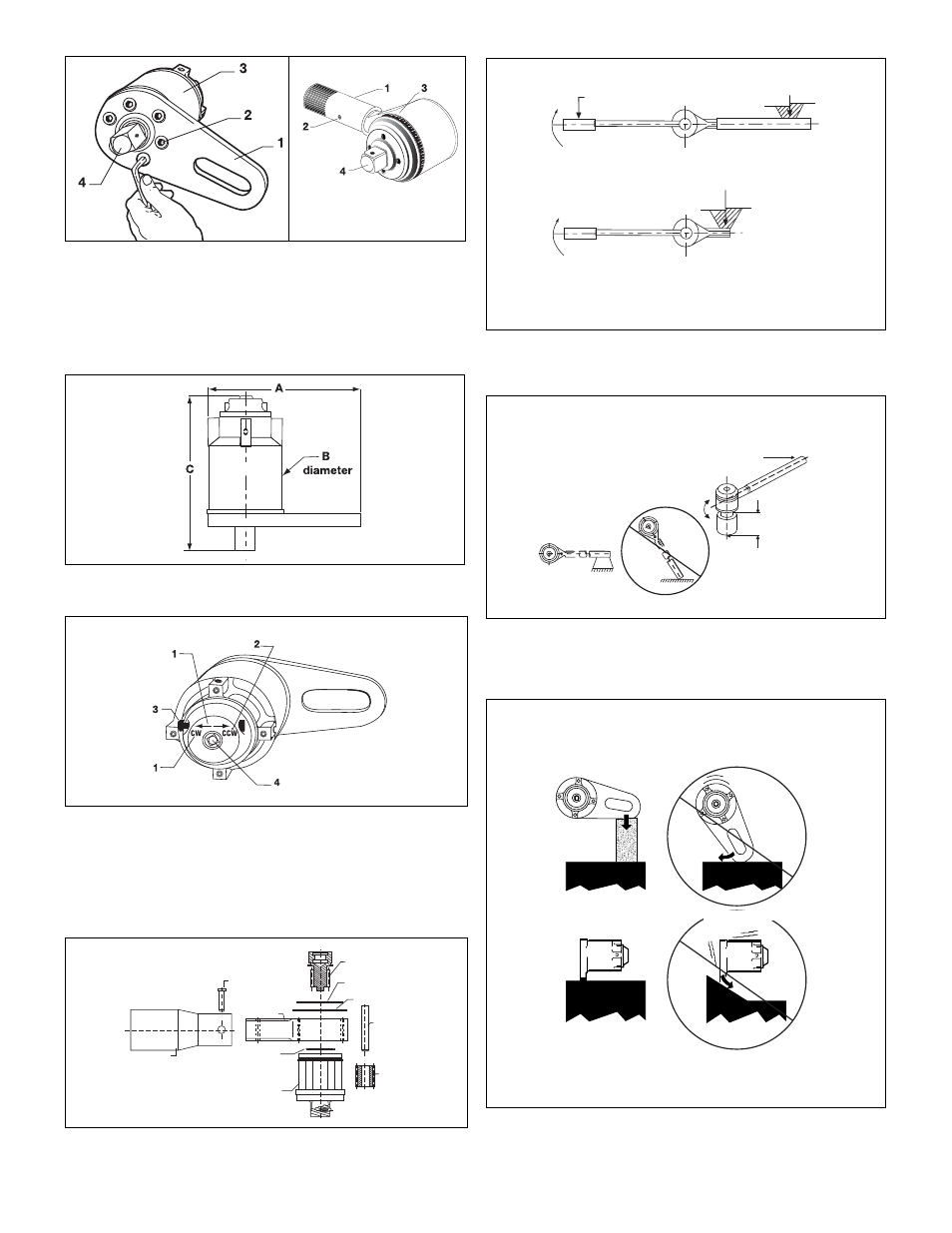

Figure 1, Changing the Reaction Plate

1. Reaction Plate / Reaction Bar

2. Socket Head Cap Screws

3. Torque Multiplier

4. Controlled-Shear Output Square Drive

Fig. 2, Torque Multiplier Dimensions

Fig. 3, Input End Detail (shown set for CW rotation)

1. Rotational direction indicators

2. Neutral positioning set screw

3. Selector pawl

4. 1/2-inch female input square drive

Fig. 4

Fig. 5, Reaction forces increase closer to the multiplier

Fig. 6, Minimize bending moments created by the torque

multiplier's reaction

Fig. 7, Keep reaction anchor perpendicular to the reaction

point.

Reaction Bar

Clevis Pin

Input Pinion

Retaining Ring

Circular Shim

Dowel Pin

Planet Gear

O-Ring

Gear Cage

Assembly

Ring Gear

Torque Wrench

2,400 lbs.

Reaction at end of standard reaction

Reaction on multiplier's reaction anchor

is opposite direction to input rotation

Keep torque

reaction at right

angle to tool.

Keep this distance

as short as possible

to reduce the

bending moment,

caused by the

torque reaction

6,360 lbs.

CORRECT

INCORRECT

CORRECT

INCORRECT