Det-Tronics EQP Fire and Gas Detection/Releasing System SAFETY MANUAL User Manual

Page 10

5.1

95-8599

8

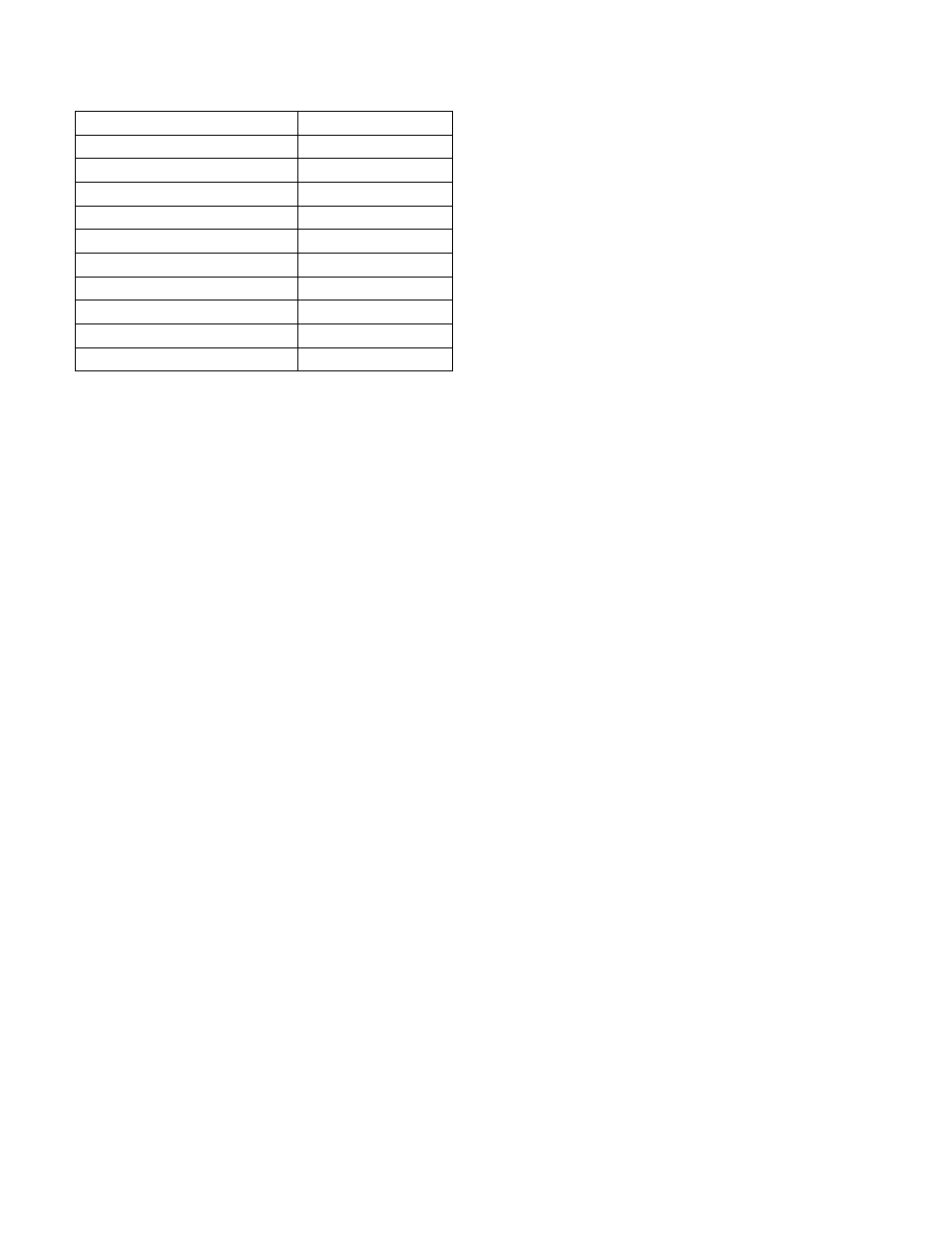

This table indicates which EDIO channel configurations

are IEC 61508 SIL rated.

Definition

SIL Rated

Unsupervised Input

No

Unsupervised Output

No

Smoke Detector

No

Class A Output

Yes

Class A Input

Yes

Solenoid Output

Yes

Class A Solenoid Output

Yes

Class A Smoke Detector Input

No

Class B Output with Monitoring

Yes

Class B Input with Monitoring

Yes

Detailed information regarding the use of the EQP

EDIO Safety Module is given in the appropriate data

sheets and user documentation (EQP instruction manual

number 95-8533). The information given here only

refers to the safety-related aspects of the module.

Outputs from the EQP Safety EDIO Module are normally

de-energized and are energized on command by the

Controller (for example to release an extinguishant by

opening a normally closed solenoid valve). Outputs will

hold last state on loss of communication with the controller.

Det-Tronics S

3

Safety System Software is used for

device configuration.

EDIO Digital Input Channel

A change in input state is only recognized if the new

input state is held for a filter time interval to ensure that

noise is not incorrectly interpreted as a change in the

input state. The input must be active for at least 750

milliseconds in order to be recognized.

For descriptions and examples of how to provide open,

and open/short circuit monitoring, and Class A or Class

B wiring on EDIO inputs, refer to the Installation section

of the EQP Instruction Manual, 95-8533. Refer to

Appendix A for the different

l

DU

values for open versus

open and short circuit monitoring.

EDIO Digital Output Channel

The EDIO output channel is normally de-energized and

must employ line supervision to be safety rated.

For descriptions and examples of how to provide open,

and open/short circuit monitoring, and Class A or

Class B wiring on EDIO outputs, refer to the Installation

section of the EQP Instruction Manual, 95-8533. Refer

to Appendix A for the

l

DU

value for open and open and

short circuit monitoring.

POWER SUPPLIES

The power supply selected must provide over-voltage

protection to the EQP System. The over-voltage

protection must be set for a maximum of 33 Vdc.

The EQP Safety System is NFPA-72 certified for use

with Det-Tronics EQP Power Supplies, power supply

monitoring, and ground fault monitoring.

Redundant power supplies can be implemented by

“pairing” supplies. This is not required for the certified

safety integrity level, but will improve availability.

The EQPSL devices must be operated between 18 and

30 Vdc. A 10% overvoltage will not damage the devices.

S

3

CONfIgURATION SOfTWARE

S

3

Software is an engineering tool for configuring

parameters and writing control programs (known as

Projects) that are downloaded to EQP Controllers. The

creation of the Project is the responsibility of the user

and must conform with the restrictions in this manual.

This Section describes the features of S

3

Software

applicable to the EQP Safety System. More general

information regarding the operation and use of S

3

can

be found in the S

3

manual (number 95-8560).

A summary of S

3

Software features specific to its use

with EQP Safety Systems is given below.

• Only input data from safety approved field devices

(X3301-SIL/Eclipse-SIL/EDIO-SIL/AIM-SIL) can be

used as safety data in EQP Safety Logic.

• Safety-related inputs and outputs are colored red to

distinguish them from non-safety related I/O.

• User function blocks that are suitable for safety-related

data are colored red to distinguish them from functions

that are not suitable for safety-related data.

• Floating point values are not safety rated and must not

be used in the safety-related logic.

• Numeric calculations are not error checked for overflow

or underflow and the results of such calculations are

not defined. It is the user’s responsibility to bound

inputs so such a condition cannot happen.

• Change control logging and event recording are

available within S

3

and EQP Safety Controllers.

While S

3

is acceptable for configuring a low demand SIL

2 EQP System, it shall not be part of the safety function.