Operation – Det-Tronics OPECL Infrared Hydrocarbon Gas Detector User Manual

Page 5

3

95-8556

10.1

COmmUNICaTION

The standard OPECL system provides an analog 4-20

mA signal output, with HART and RS-485 MODBUS serial

communication from the receiver module. EQP Models

communicate with the EQP controller over the LON.

RECORDINg CapabIlITy

Non-volatile memory is provided to save the 10 most

recent calibrations, alarm/fault events, and minimum/

maximum operating temperature history. A real time

clock is provided to record operating service time and to

time stamp events. This information is accessible using

HART and MODBUS communication, or S3 software for

EQP models.

DETECTION RaNgE

The standard OPECL system can cover a range of 5 to

120 meters.

opERation

mODUlE IDENTIfICaTION

While the OPECL transmitter and receiver modules

appear physically identical, each module is labeled as

“transmitter” or “receiver” on the enclosure. The physical

mounting requirements for both modules are generally

identical. However, there are functional and electrical

characteristic differences as identified in Table 1.

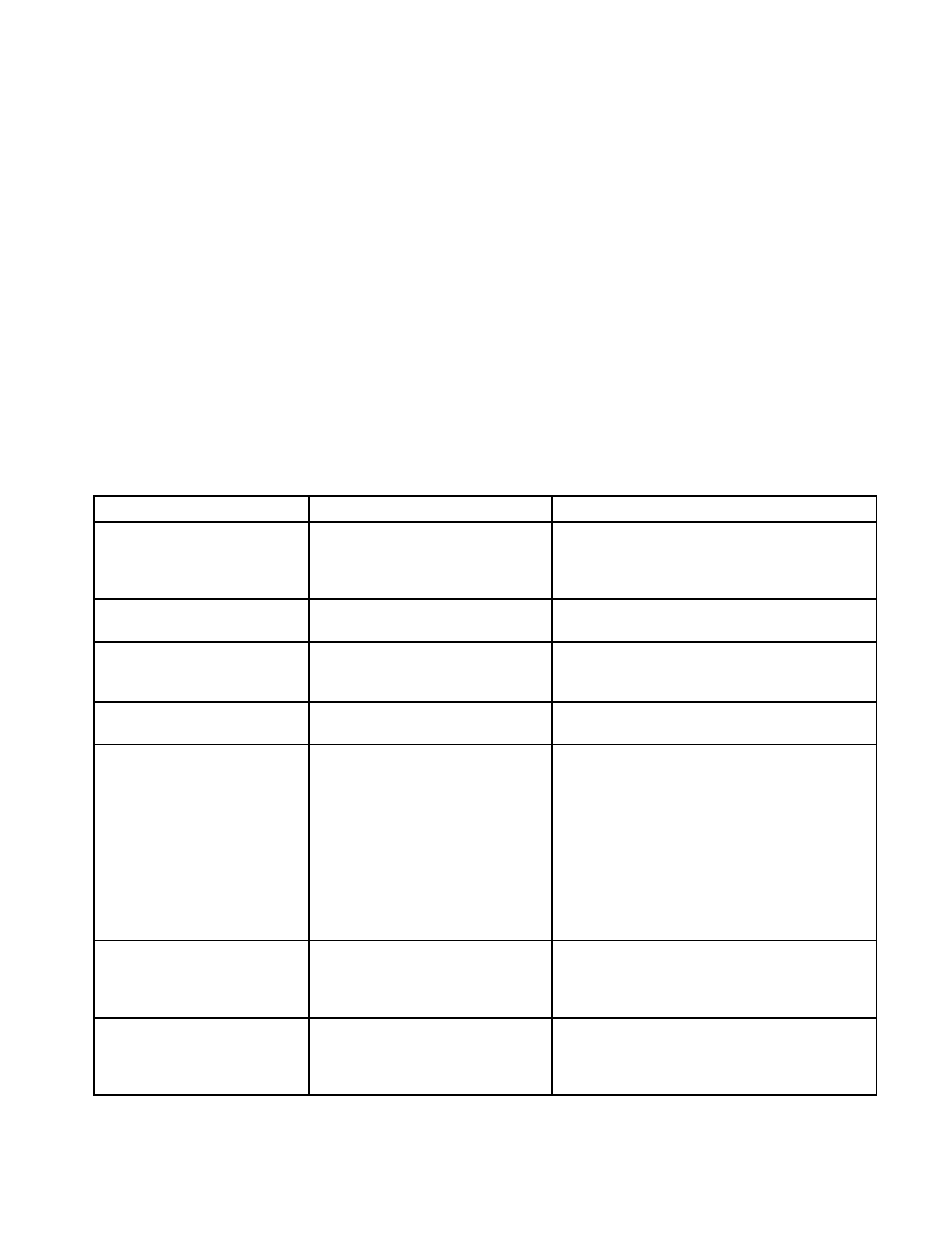

Table 1—Functional and Electrical Comparison of Transmitter and Receiver

Characteristic

Transmitter (Tx)

Receiver (Rx)

Functional Description

Contains primary and backup xenon

flashlamps, and generates optical

energy to enable hydrocarbon

detection.

Contains opto-electronics, signal processing and

output drivers, and diagnostic electronics.

Power Consumption

5.0 watts nominal @ 24 Vdc.

5.8 watts peak @ 24 Vdc.

6.0 watts nominal @ 24 Vdc (without relays).

6.4 watts nominal @ 24 Vdc (with relays).

Electrical Connections

2 power connections only.

(+24 Vdc and –24 Vdc).

From 3-7 connections depending upon specific

configuration (separate power and signal cables

recommended).

Onboard HART Communication

Port

N/A

Connection to handheld HART communicator for

system setup, commissioning, and diagnostics.

Onboard LED Indicator

Indicates normal, fault, and backup

lamp operation status.

Green indicates normal operation.

Yellow indicates operation in “back-up

lamp” mode or other fault condition.

Indicates normal, alarm, fault, and calibration status.

Green indicates normal operation. Blinking red

indicates low gas alarm condition.

Steady red indicates high gas alarm condition.

Yellow indicates operation in “back-up lamp” mode

or system fault.

Calibration status is indicated by a steady red

indication after Calibration command.

LED operation for fault status is non-latching. LED

operation for gas alarms is configurable for latching/

non-latching.

Magnetic Calibration Switch

(See Figure 2 for switch location.)

Momentary activation overrides back-

up lamp fault flash coding sequence,

permitting normal receiver operation

with back-up lamp.

Momentary activation provides reset function for

latched alarm outputs. Activation for longer than 2

seconds will initiate zero calibration.

Factory Default Settings

No programmable options

Factory calibrated for methane, 0-5 LFL-meters

full scale. See Table 2 for receiver factory default

settings. HART communication is required to

change the factory default settings.