Device repair and return – Det-Tronics OPECL Infrared Hydrocarbon Gas Detector User Manual

Page 28

26

95-8556

10.1

noTe

If the replacement module is a receiver and is

used in an eQP system, it will have Lon address

switches that must be set. Set the switches on

the new module the same as the switches on

the module being replaced

before installing the

module into the bulkhead.

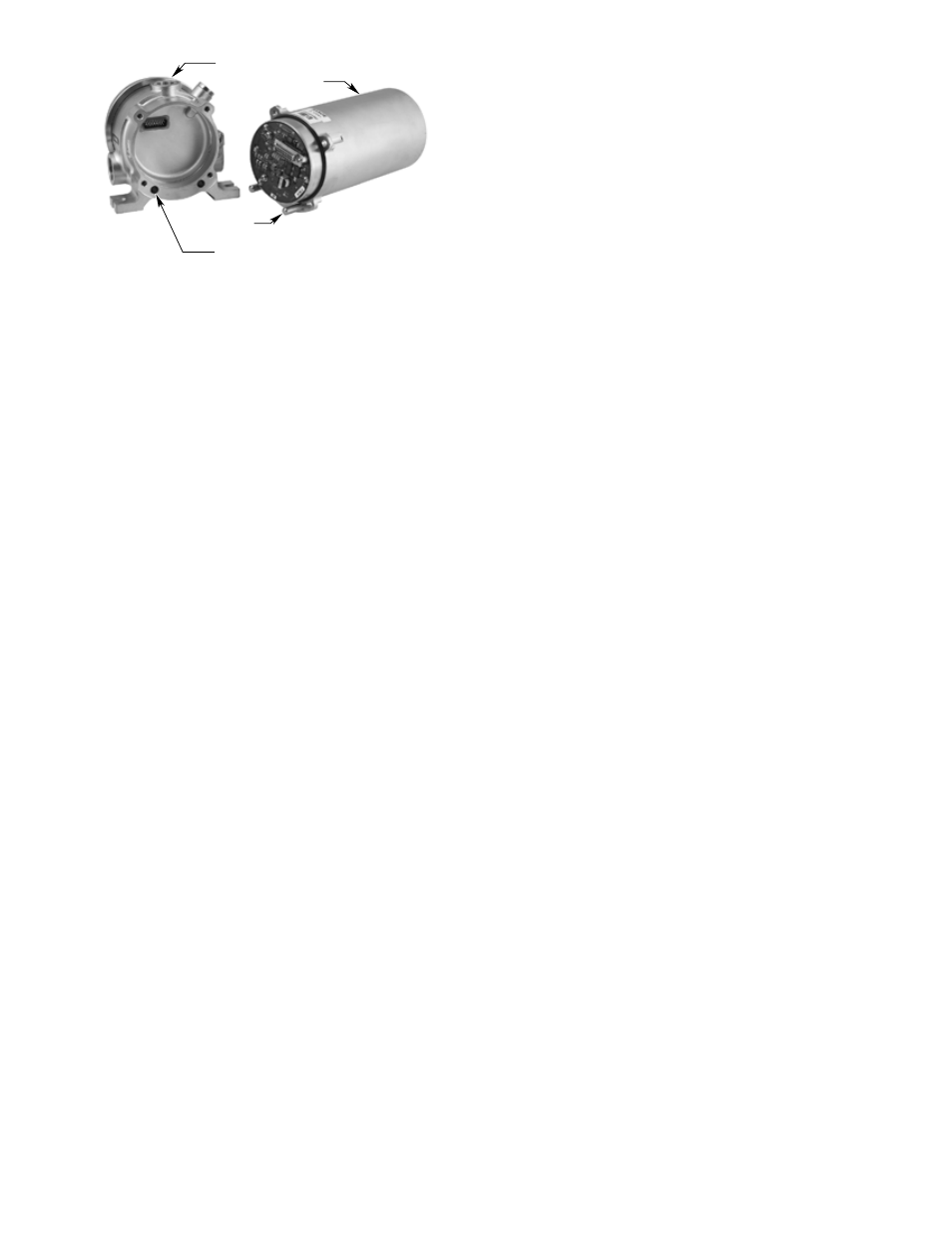

5. Line up the two pins on the replacement module with

the two holes in the bulkhead and insert the module

straight into the bulkhead. See Figure 24.

6. Insert and tighten the four flange bolts in an

opposing consecutive order in two stages — first

partially tighten all four bolts equally, and then

fully tighten each bolt in an opposing order to 40

inch-pounds (4.5 Nm) of torque. Bolts are M6 per

ISO 965 with M5 head, SST with a yield stress of 448

N/mm

2

(65.00 PSI) minimum.

CaUtIon

Flange bolts are critical to maintaining the

flameproof properties of the oPeCL. If

replacement flange bolts are needed, DeC spare

part number 007167‑001 must be used in order to

maintain the integrity of the enclosure. The use of

any other bolts will void the ex d certification of the

oPeCL.

7. When all equipment has been properly installed,

ensure that system alarms are appropriately

bypassed and apply power to the system.

8. Perform the alignment procedure as previously

described in this manual.

Important

If the oPeCL module had an aperture installed,

install the aperture before performing the

alignment procedure (install apertures on the

transmitter, not on the receiver). If the separation

distance is between 5 and 30 meters and signal

saturation is indicated after completion of the

Basic Alignment procedure, an aperture will

be required (even if no aperture was originally

installed). Refer to the "Aperture Kit for Short

Range Applications" section in this manual for

complete information regarding apertures.

9. Perform a zero calibration of the detector.

10. Upon completion of zero calibration, verify proper

operation by performing an “optical test film

test” and also a “beam block test” as previously

described in this manual.

noTe

Replacement receiver modules are furnished from

the factory with default configuration settings. If

the oPeCL system has had any configuration

changes in the field, the new receiver will require

changes to configuration parameters using a

HART communicator or a FlexVu UD10 display unit

(use S3 software for eQP models).

11. Restore system alarms (remove bypass).

dEvicE REpaiR and REtuRn

The Open Path Eclipse IR Hydrocarbon Gas Detector

is not designed to be repaired in the field. If a problem

should develop, first carefully check for proper wiring,

programming and calibration. If it is determined that the

problem is caused by an electronic failure, the device

must be returned to the factory for repair.

Prior to returning devices, contact the nearest local

Detector Electronics office so that a Return Material

Identification (RMI) number can be assigned. a

written statement describing the malfunction must

accompany the returned device or component to

assist and expedite finding the root cause of the

failure.

Pack the unit properly. Always use sufficient packing

material. Where applicable, use an antistatic bag as

protection from electrostatic discharge.

noTe

Inadequate packaging that ultimately causes

damage to the returned device during shipment

will result in a service charge to repair the damage

incurred during shipment.

Return all equipment transportation prepaid to the

factory in Minneapolis.

OPECL MODULE

BULKHEAD

ALIGNMENT

PIN (2)

TO INSTALL REPLACEMENT MODULE, LINE UP

PINS (2) WITH HOLES IN BULKHEAD AND

INSERT MODULE FULLY INTO BULKHEAD.

A2500

Figure 24—OPECL Module Removed from Bulkhead