Det-Tronics OPECL Infrared Hydrocarbon Gas Detector User Manual

Page 24

22

95-8556

10.1

C. If adjustments to the receiver were necessary,

perform a zero calibration and then repeat the

sequence of partial beam blocks. Repeat the

adjust, zero calibration, and recheck process until

no adjustments to the receiver are necessary, and

the partial beam block has little or no effect on the

receiver under test.

10. With the beam block tool removed, the Ratio reading

must be between 0.65 and 0.95. If a reading over

1.0 is indicated, check to make sure that no other

transmitters, IR sources, or potential reflections are

within view of the receiver. It is possible for multiple

transmitters to be viewed by a single receiver.

Although each receiver is electronically synchronized

to its transmitter, zero drift and/or false gas readings

are possible if the rogue IR source continues in the

event of a beam block on the primary transmitter.

If this situation occurs, a ratio of over 1.0 will be

realized. Det-Tronics recommends eliminating any

condition that causes a receiver to display a ratio of

over 1.0.

11. When correct alignment is achieved, tighten all

mounting bolts to 20 lb-ft minimum using care not

to disturb the alignment. The telescope can be

used during this step to give a visual indication to

judge the effects of the tightening process on the

alignment. Check the alignment one final time using

the beam block tool to verify that the alignment did

not change as a result of tightening. If necessary,

fine tune the alignment.

12. Upon completion, the OPECL receiver should

produce a 4 mA output signal and a green LED

indication. If not, ensure that the device has been

zero calibrated.

13. Proper operation can be confirmed by bypassing

all system alarms, then placing an optical test film

(sold separately) into the light beam and checking

for the appropriate signal output level on the HART

field communicator process menu screen. Test

Film p/n 007902-002 should produce an output of

0.5 to 1.1 LFL-Meters. Test Film p/n 007902-003

should produce an output of 1.5 to 2.1 LFL-Meters.

Alarm conditions, if present, should clear when the

test film is removed from the beam.

14. Confirm proper operation by completely blocking

the light beam with a solid object such as a piece of

cardboard until a beam block fault is generated.

15. Replace the HART port cover and the brow.

16. Restore all system alarms to normal operation.

gaIN lEvEl ChECK (Optional)

It is necessary to complete the alignment procedure

before checking the gain level. A handheld HART

communication device (or S3 Software for an EQP

system) is required to check the gain.

procedure

1. Connect the handheld HART communicator to the

receiver module’s onboard HART communication

port.

2. Turn on the HART communicator and check

for OPECL device recognition. When HART

communication is established, the OPGD Rx Root

menu will be displayed on the communicator display.

3. From the Root menu, select the Status Menu

(selection #2).

4. From the Status Menu, select the Sensor Information

Menu (selection #3).

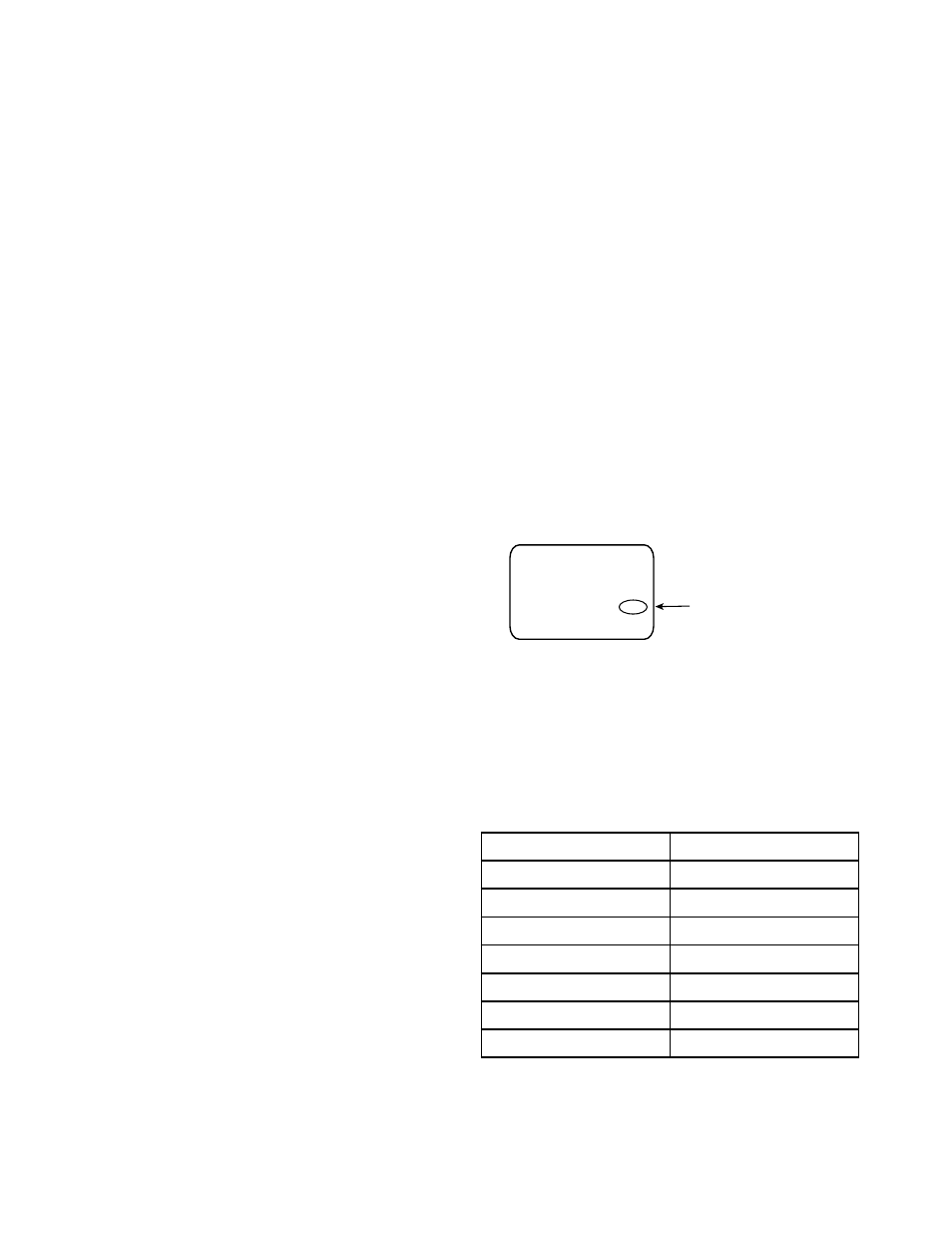

5. The Sensor Information Menu will display the

following screen.

6. Observe the Gas Gain level indicated on the Sensor

Information Menu screen.

7. Table 4 can be used as a guideline for new

installations to assess Gas Gain level with proper

alignment.

1) Active

XXX

2) Reference

XXX

3) Ratio

XXX

4) Gas Gain

X

5) Absorption

XXX

Gas Gain number

Table 4— Expected Gas Gain Settings for OPECL

Distance (m)

gain Setting

5

1-3*

20

1*

40

1 - 2

60

2

80

2 - 3

100

3

120

3 - 4

*Use the Aperture Kit to get desired gain settings.