Det-Tronics OPECL Infrared Hydrocarbon Gas Detector User Manual

Page 21

19

95-8556

10.1

8. Slowly adjust the receiver module left/right as

required using the horizontal adjustment bolts until

the telescope cross hairs are centered as close as

possible to dead center on the transmitter module

window. Tighten the horizontal adjustment bolts and

locking nuts so that no movement will occur.

9. Rotate the telescope alignment tool by 180° and

verify that the cross hairs are in the same position.

If the cross hairs are not in the same position, the

telescope alignment screws must be adjusted as

follows:

A. Adjust the telescope alignment screws until the

cross hairs are midway between the original

position (center of transmitter window) and the

current position (after the scope was rotated

180°). See Figure 20.

B. Return the scope to its original position (rotate

180°) and repeat steps 7 through 9 until correct

alignment is achieved.

noTe

no further adjustments are required when the

cross hairs are centered on the window with the

scope in both 180° positions.

10. Repeat the alignment procedure for the transmitter

module (steps 6 to 9).

11. Re-check the receiver for correct alignment (steps 6

to 9) and adjust as needed.

12. Remove the Telescopic Alignment Tool and re-install

the brow.

13. Bypass all external gas alarm devices that are

connected to the receiver outputs, and then apply

24 Vdc power to the modules.

14. Upon completion of warm-up mode (approximately

2 minutes or less), the receiver may display either

a green LED (normal mode) or a red LED (alarm

mode). An alarm condition is not abnormal and will

be cleared by performing a zero calibration.

15. For installations with module separation distances

between 5 and 30 meters, install the appropriate

aperture as described in the "Aperture Kit for Short

Range Applications" section.

16. Perform a zero calibration. (Refer to “Zero

Calibration” in the Calibration section of this

manual.) Any faults or alarms that may be present

as a result of the alignment process will be cleared.

17. When Basic Alignment and Zero Calibration have

been successfully completed, a green LED should

be displayed on the Rx module and the analog

signal output level should be 4.0 milliamperes.

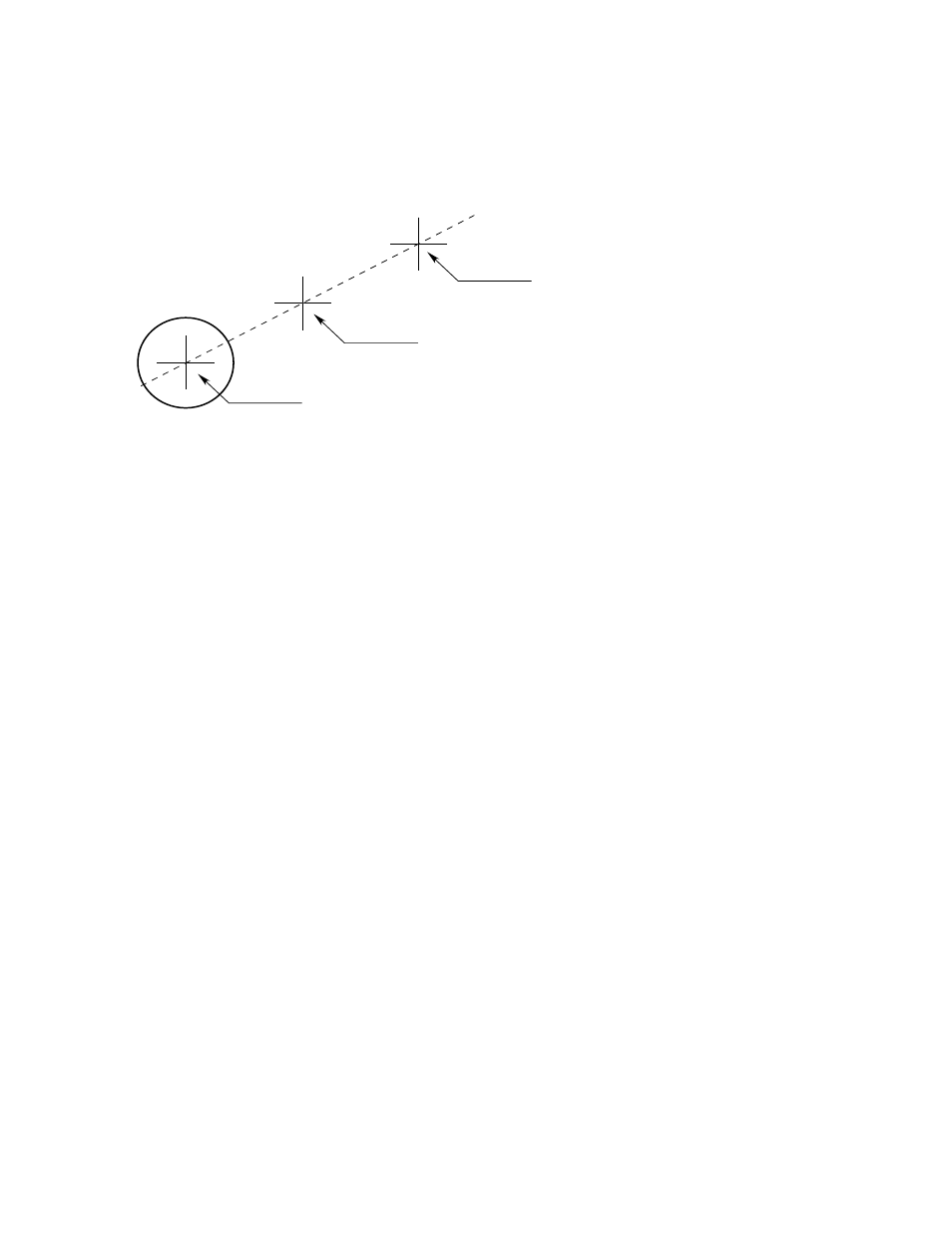

POSITION A = ORIGINAL ALIGNMENT

POSITION B = CROSS HAIR POSITION AFTER ROTATING SCOPE 180°

POSITION C = MIDWAY BETWEEN POSITION A AND B

STEP 1: CENTER CROSS HAIRS ON TARGET USING

ADJUSTMENT BOLTS ON MOUNTING PLATE

(POSITION A).

STEP 2: ROTATE SCOPE 180°. ALIGNMENT

ERROR CAUSES CROSS HAIRS TO

MOVE TO POSITION B.

STEP 3: ADJUST ALIGNMENT SCREWS ON SCOPE

TO PLACE CROSS HAIRS AT POSITION C.

STEP 4: ROTATE SCOPE 180° TO ORIGINAL POSITION.

STEP 5: REPEAT STEPS 1 TO 4 UNTIL THE UNIT IS

CORRECTLY ALIGNED.

A2314

Figure 20—OPECL Alignment using the Telescope Alignment Tool