Daily inspection and maintenance, Daily inspection and maintenance table 7-1, Daily inspection and maintenance table, 7-1 – Snorkel SR2770 User Manual

Page 32: Operators daily inspection, 7-1, Inspection and maintenance table, 7-1, Qualified, 7-1, Daily inspection and maintenance table -1, Danger

7. Daily Inspection and Maintenance

At the start of each work day (or 8 hour shift), an SR

qual i fied op er a tor must per form the Daily In spec -

tion and Main te nance as listed in the ta ble be low.

The pur pose of the Daily In spec tion and Main te -

nance is to keep the SR in proper work ing con di tion

and to de tect signs of mal func tion at the ear li est

pos si ble time.

Set the Key Switch set to OFF be fore you be gin

this in spec tion.

De fec tive parts and/or equip ment mal func tions

jeop ar dize the safety of the op er a tor and other per -

son nel, and can cause dam age to the ma chine.

DO NOT operate an SR that is known to be

damaged or malfunctioning.

R e p a i r a l l e q u i p m e n t d a m a g e o r

malfunctions, before placing the SR into

service.

SR2770 – 11669A

page 7 - 1

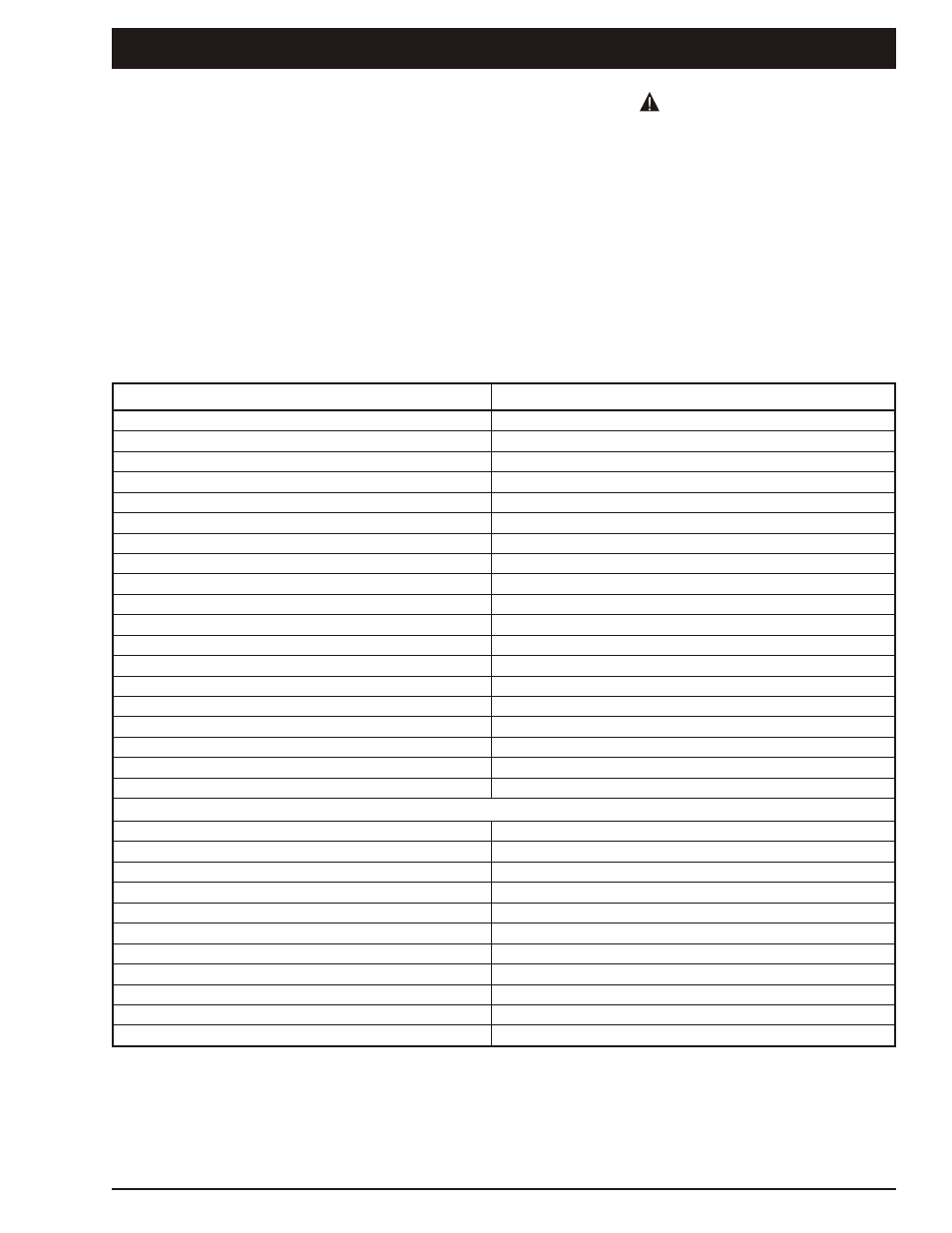

Item

Service Required

Fuel level

Visually inspect

Fuel filter (diesel engines only)

Visually inspect (condition)

Fuel leaks

Visually inspect (hoses and connections etc)

Engine oil

Check oil level (between dipstick lines)

Engine coolant

Check fluid level and radiator hoses

Radiator cap

Visually inspect installation)

Swinging gate

Visually inspect (installation, operation)

Wiring harnesses and connectors

Visually inspect (installation, operation)

Battery terminals

Visually inspect (no corrosion)

Hydraulic tank cap

Visually inspect installation)

Hydraulic oil level

Check fluid level (at line on side of tank)

Hydraulic oil leaks

Visually inspect (hoses,tubes)

Tires and wheels

Visually inspect (condition)

Bolts and fasteners

Visually inspect (looseness)

Structural damage and welds

Visually inspect (welds, cracks, dents)

Guardrails

Visually inspect (condition)

Lanyard anchorages (option)

Visually inspect (condition)

Bubble level on platform

Visually inspect (condition)

Guides, rollers and slides

Visually inspect (condition)

START THE ENGINE FROM THE GROUND CONTROL BOX

Charging system

Check condition (gauge)

Level sensor

Check operation

Ground controls

Actuate and visually inspect for operation

Emergency lowering

Check operation (causes correct motion)

Platform controls

Actuate and visually inspect for operation

Flashing light (option)

Visually check (operation)

RCD / ELCB (option)

Check operation

Air filter

Check condition (gauge)

Safety prop

Check operation

Parking brakes

Check operation

Placards, decals, and Operators Manual

Visually inspect (installation and condition)

■ Daily Inspection and Maintenance Table

DANGER