Burnham MPC User Manual

Page 74

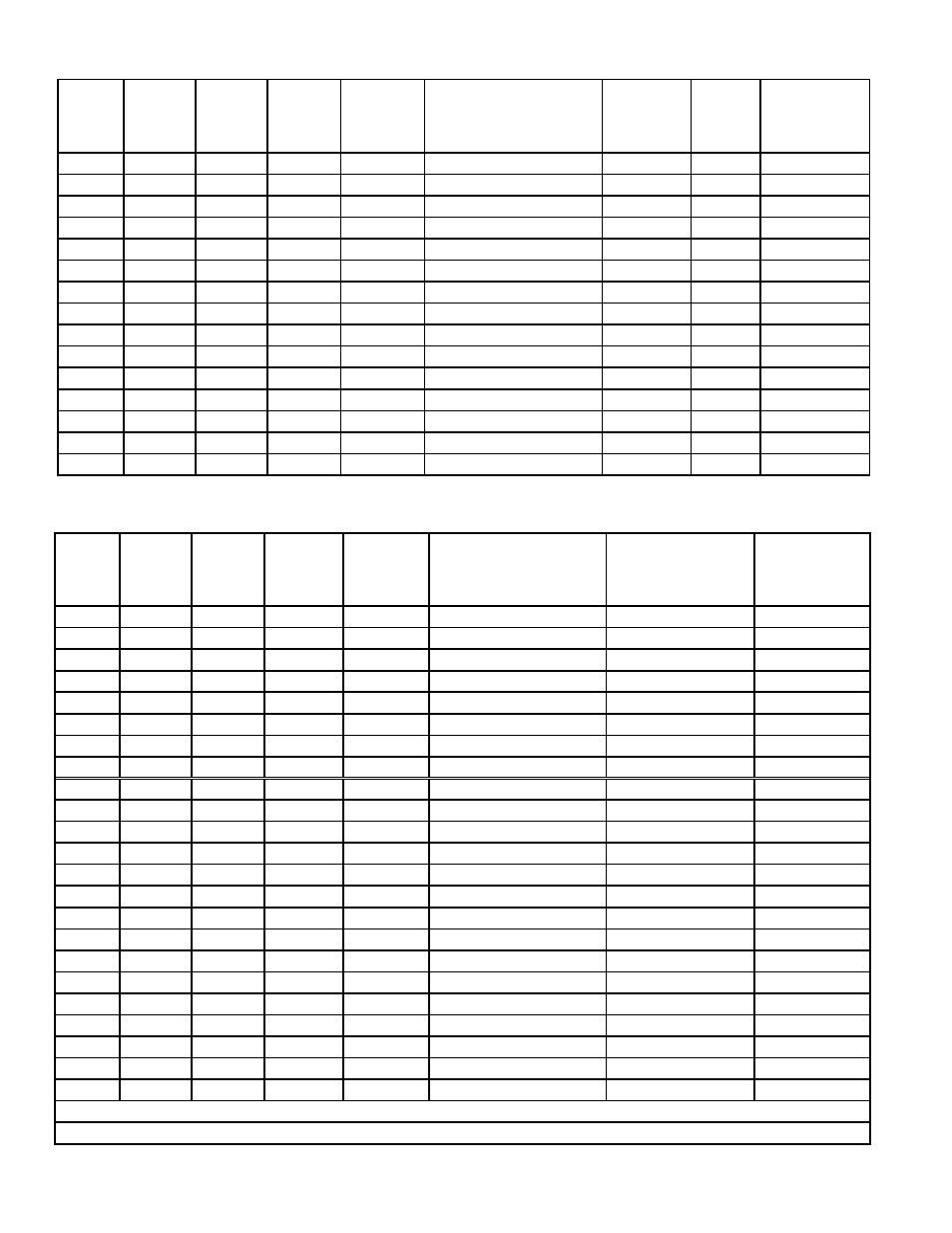

7

BOILER

MODEL

BURNER

MIN.

INPUT

(GPH)

BURNER

MAX.

INPUT

(GPH)

BURNER

MODEL

DIFFUSER

OPENING

(IN.)

APPROX. HIGH FIRE

DAMPER SETTING -

TOP / BOTTOM DAMPER

(IN.)

HIGH FIRE

PUMP

PRESSURE

(PSI)

NOZZLE

MAKE

NOZZLE DATA

GPH X ANGLE

- TYPE

MPC4

3.0

3.55

C1-O

3/16

5/16 / Closed

300

Delavan

2.5 X 90 - B

MPC5

3.0

5.5

C1-O

3/8

1 / Closed

300

Delavan

3.5 X 80 - B

MPC6

3.0

7.1

C1-O

1/4

1-3/32 / 1-3/8

270

Delavan

4.5 X 90 - B

MPC7

3.0

8.7

C1-O

1/4

3/4 / 3/4

270

Delavan

6.0 X 90 - B

MPC8

5.5

10.2

C2-OA

1/4

1 / Closed

300

Monarch

6.5 X 80 - PLP

MPC9

5.5

11.8

C2-OA

1/4

13/16 / 11/16

300

Monarch

7.0 X 80 - PLP

MPC10

5.5

13.4

C2-OA

3/16

Both Wide Open

250

Monarch

8.5 X 80 - PLP

MPC11

5.5

15.0

C2-OA

3/8

1-3/8 / 1-1/4

260

Monarch

9.5 X 70 - PLP

MPC12

5.5

16.6

C2-OB

3/8

1-3/4 / 1-3/4

300

Monarch

10.5 X 70 - PLP

MPC13

5.5

18.2

C2-OB

3/8

1-1/2 / 1-1/4

300

Monarch

11.0 X 80 - PLP

MPC14

5.5

19.8

C2-OB

1/2

1-1/4 / 1-1/4

270

Monarch

12.0 X 80 - PLP

MPC15

5.5

21.5

C3-O

1/2

1-7/8 / Closed

280

Hago

14.0 X 80 - BPS

MPC16

7.4

23.0

C3-O

5/16

1-3/4 / 1-3/4

225

Hago

16.0 X 80 - BPS

MPC17

7.4

24.5

C3-O

3/8

2 / 2

280

Hago

15.0 X 80 - BPS

MPC18

7.4

26.0

C3-O

3/8

Both Wide Open

300

Hago

16.0 X 80 - BPS

Table XIVa: Power Flame #2 Oil Burner Specifications

BOILER

MODEL

BURNER

MIN.

INPUT

(MBH)

BURNER

MAX.

INPUT

(MBH)

BURNER

MODEL

DIFFUSER

OPENING

(IN.)

APPROX. HIGH FIRE

DAMPER SETTING -

TOP / BOTTOM DAMPER

(IN.)

APPROX. NAT. GAS

MANIFOLD PRESS.

AT ORIFICE TEE

(“WC)

MINIMUM

NAT. GAS

INLET PRESS.

(“WC) **

MPC4

300

500

JR15A-10

N/A

1/2 *

1.2

4.0

MPC5

300

773

JR30A-12

N/A

3/4 *

1.5

4.2

MPC6

300

995

JR30A-12

N/A

13/16 *

2.5

4.9

MPC7

600

1216

JR30A-12

N/A

1-3/32 *

3.5

5.6

MPC8

650

1438

JR50A-15

N/A

3/4 *

2.0

5.9

MPC9

650

1660

JR50A-15

N/A

Wide Open *

1.5

6.9

MPC10

650

1881

JR50A-15

N/A

3*

1.8

5.8

MPC11

650

2103

JR50A-15

N/A

2-3/8*

2.1

5.0

MPC4

300

500

C1-G-10

3/16

5/16 / Closed

1.8

4.0

MPC5

300

773

C1-G-10

3/8

1 / Closed

3.8

4.4

MPC6

300

995

C1-G-12

1/4

1-3/32 / 1-3/8

2.4

4.8

MPC7

300

1216

C1-G-12

1/4

3/4 / 3/4

3.5

5.5

MPC8

750

1438

C2-G-15

1/4

1 / Closed

1.0

6.0

MPC9

750

1660

C2-G-15

1/4

13/16 / 11/16

1.4

6.8

MPC10

750

1881

C2-G-20A

3/16

Both Wide Open

2.6

5.9

MPC11

750

2103

C2-G-20A

3/8

1-3/8 / 1-1/4

2.0

6.5

MPC12

750

2325

C2-G-20A

3/8

1-3/4 / 1-3/4

2.4

5.7

MPC13

750

2547

C2-G-20B

3/8

1-1/2 / 1-1/4

2.9

6.5

MPC14

750

2769

C2-G-20B

1/2

1-1/4 / 1-1/4

3.0

6.5

MPC15

900

2991

C3-G-20

1/2

1-7/8 / Closed

1.7

5.6

MPC16

900

3213

C3-G-20

5/16

1-3/4 / 1-3/4

2.3

6.9

MPC17

900

3435

C3-G-20

3/8

2 / 2

2.6

6.6

MPC18

900

3657

C3-G-20

3/8

Both Wide Open

2.5

6.8

* ON “JR” BURNERS, THIS DIMENSION IS THE GAP BETWEEN THE TWO DAMPER BLADES.

** MINIMUM INLET PRESSURE FOR STANDARD UL GAS TRAINS ONLY. CONSULT FACTORY FOR ADDITIONAL INFORMATION.

Table XIVb: Power Flame Gas Burner Specifications