Burnham MPC User Manual

Page 31

1

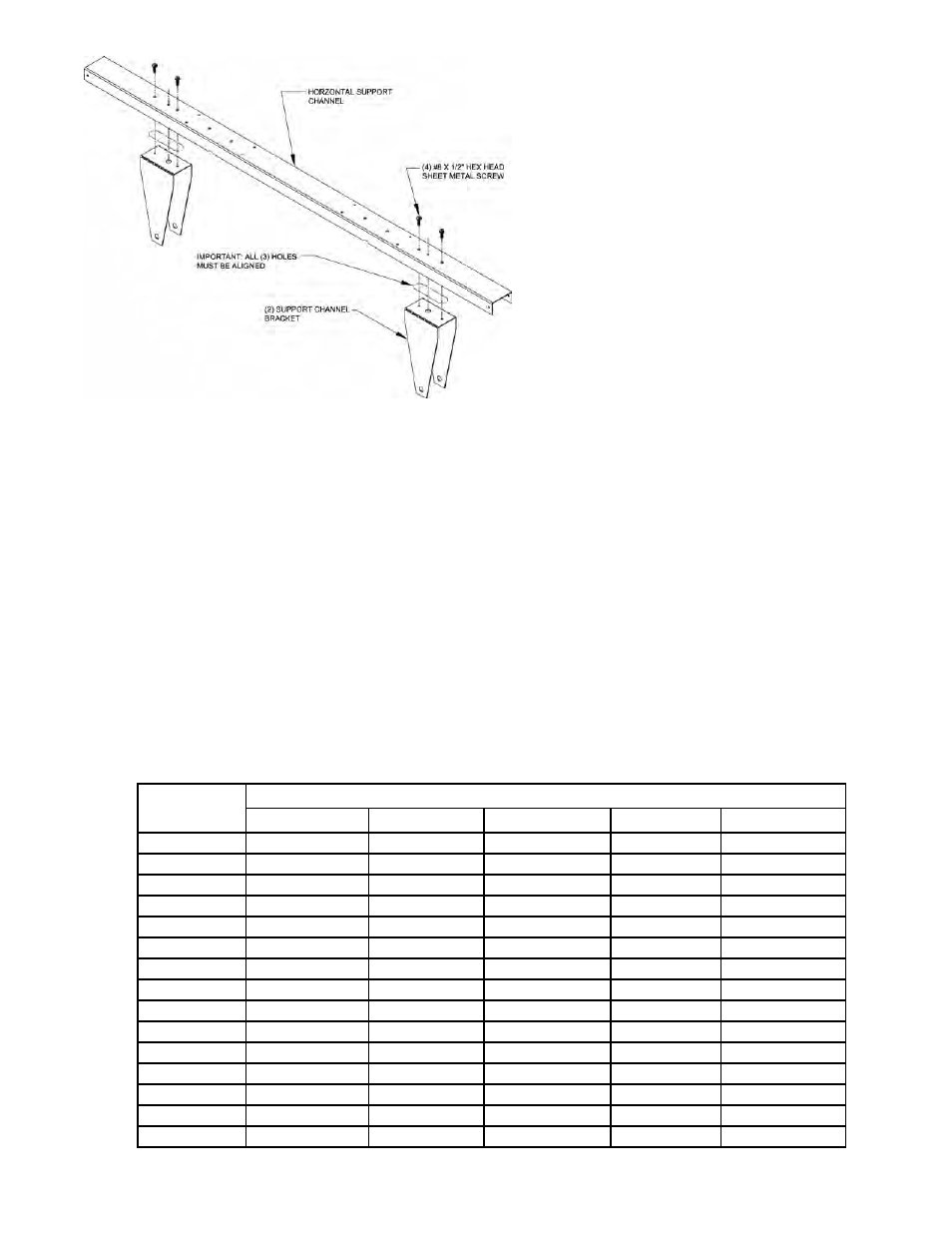

5. Add front/center section mounting hardware to all

but one (1) horizontal support channel assembly.

Lay channel assembly on floor with brackets facing

up, see Figure 17a. Install hardware as shown

with two (2) washers and two (2) 1/2” lg. spacers

between bracket legs and one (1) washer and one (1)

hex nut on each end of 3/8” -16 x 3-1/4” lg. rod, see

assembled end view in Figure 17a. Repeat for all

brackets.

6. Add rear section mounting hardware to remaining

horizontal support channel assembly. Lay channel

assembly on floor with brackets facing up, see

Figure 17b. Install hardware as shown with one

(1) 1-3/4” lg. spacer between bracket legs, one (1)

washer and one (1) hex nut on one end of 3/8” -16

x 13-3/8” lg. threaded rod, with one (1) washer,

one (1) 2-5/8” lg. spacer, two (2) washers and one

(1) hex nut on the opposite end of rod. Repeat for

second bracket, refer to assembled end view in

Figure 17b.

7. Mount

front/center horizontal channel

assembly(lies) to appropriate casting(s) on block

assembly as outlined in Table VIII. Position

threaded rods on channel assemblies over slotted

lugs on casting as shown in Figure 18a. Spread

inside washers until rod drops to bottom of slot

as shown in Figure 18a, Detail ‘A’. Hand tighten

nuts, make sure washers engage casting below

washer retaining lugs, see Detail B. Repeat for all

remaining bracket attachment points.

8. Mount rear horizontal channel assembly to rear

section and adjacent center section as shown in

Figure 18b. Position assembly behind supply

manifold, spread washers and lower threaded rod

into slotted openings on both castings as shown in

Figure 18b, Detail A. Hand tighten nuts, make sure

washers engage casting below washer retaining lugs

as shown in Detail B. Repeat for opposite side.

9. Wrench tighten hex nuts on all channel assemblies

making sure rods are fully seated in slotted

openings.

10. Locate and install lower

front/center section

brackets to casting legs. Brackets are universal and

can be used on either side of block assembly. Refer

to Table VIII for appropriate casting leg to be used

for bracket attachment. Brackets mount to rear

surface of leg with offset toward the rear as shown

in Figure 19. Hold bracket at a 45° angle while

engaging upper slot over threaded tie rod, rotate

bracket around rod until lower slot is aligned with

lower hole in casting leg. Insert 5/8 -11 x 2” lg.

bolt with washer through cast hole in leg and slot in

bracket.

Figure 16: Secure Brackets to Horizontal Channel

Boiler Size

Front

f Block Assembly g Rear

Frame 1

Frame 2

Frame 3

Frame 4

Frame 5

4 Section

Front Section

Rear Section

-----

-----

-----

5 Section

Front Section

Rear Section

-----

-----

-----

6 Section

Front Section

Rear Section

-----

-----

-----

7 Section

Front Section

Section 4

Rear Section

-----

-----

8 Section

Front Section

Section 5

Rear Section

-----

-----

9 Section

Front Section

Section 5

Rear Section

-----

-----

10 Section

Front Section

Section 6

Rear Section

-----

-----

11 Section

Front Section

Section 6

Rear Section

-----

-----

12 Section

Front Section

Section 5

Section 9

Rear Section

-----

13 Section

Front Section

Section 5

Section 9

Rear Section

-----

14 Section

Front Section

Section 5

Section 10

Rear Section

-----

15 Section

Front Section

Section 6

Section 11

Rear Section

-----

16 Section

Front Section

Section 6

Section 11

Rear Section

-----

17 Section

Front Section

Section 5

Section 9

Section 13

Rear Section

18 Section

Front Section

Section 5

Section 10

Section 14

Rear Section

Table VIII: Frame/Bracket Mounting Locations