Burnham MPC User Manual

Page 63

6

a. Temperature and Flow Requirements – An

existing parallel piping system may be used,

provided the return water is not below 80°F and

the return water temperature is not more than

80°F less than the boiler outlet temperature. A

flow analysis should be performed to determine

the flow through the boiler when the minimum

(and smallest) and maximum number of zones

are activated.

Sufficient flow through the boiler must be

maintained. The recommended maximum

temperature difference between the boiler supply

and return water is 40°F. However, a maximum

delta T of 80°F across the boiler is allowable.

A minimum boiler supply water temperature of

130°F must be maintained to avoid sustained

condensing within the combustion chamber.

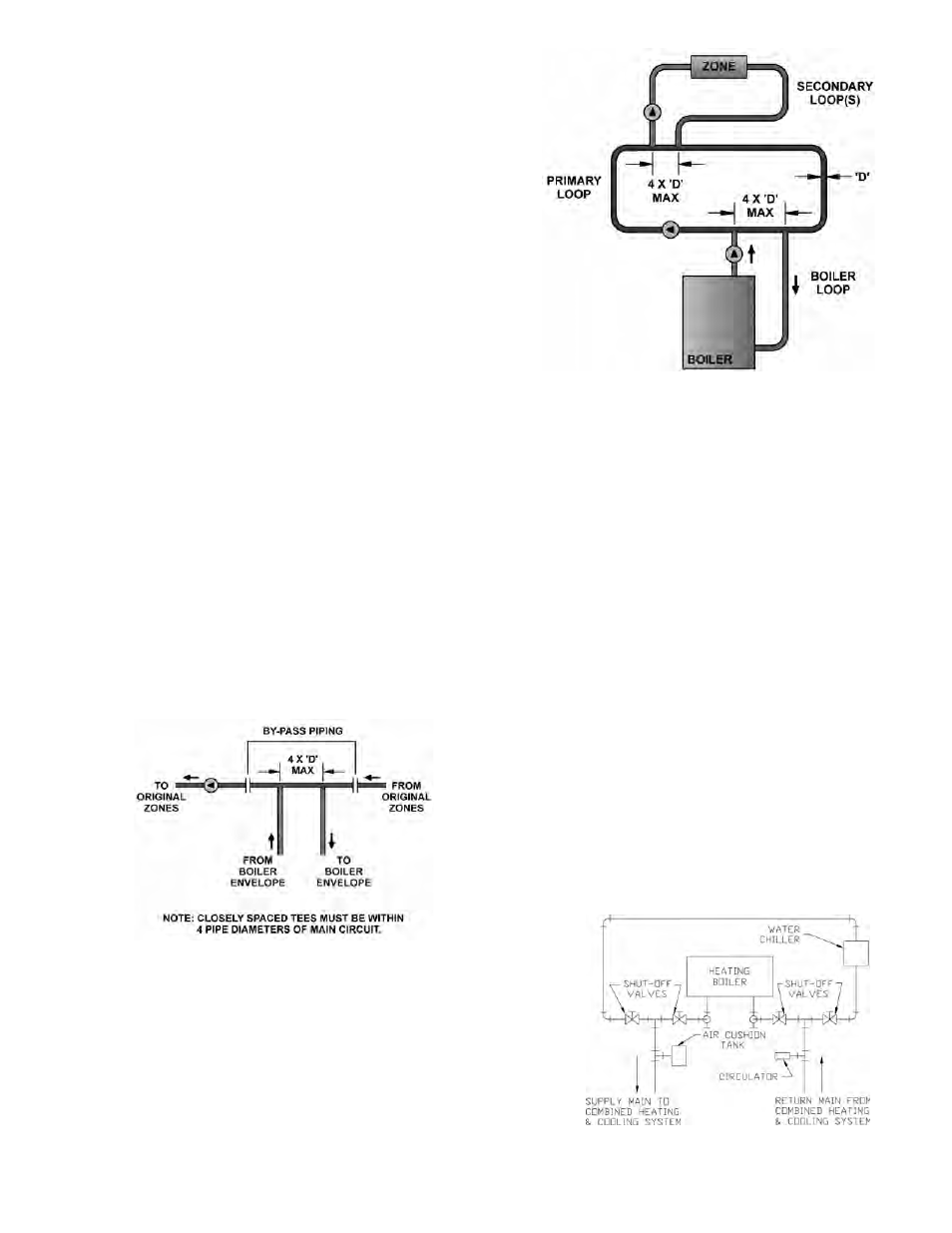

b. Primary/Secondary Piping - If the conditions

above cannot be met, then parallel piping

systems must be converted to an arrangement

that will provide the proper water flow through

the boiler at the proper temperatures. Primary/

Secondary piping is a common method for

isolating the boiler from the system. The

concept must be for the boiler loop to inject

heat into a primary loop, provided the return

water into the boiler is at least 80°F. A by-pass

containing two closely spaced tees must be

installed to de-couple the boiler loop from the

primary loop (see Figure 51). The converted

system should resemble Figure 52. Care must

be taken to avoid dead heading the system pump.

Conversions should be reviewed and approved

by a Consulting Engineer or other qualified

professional to avoid system deficiencies.

Figure 51: Parallel Piping Conversion

c. Alternate Piping Arrangements - Piping

arrangements other than Parallel and Primary/

Secondary, such as System Bypass, are

acceptable as long as they ensure that the flow

and temperature requirements of the boiler are

met.

d. Glycol Antifreeze Solutions - Many systems

today use ethylene or propylene glycol antifreeze

solutions as a measure for freeze protection, as

well as a pump lubricator and corrosion inhibitor.

The properties of the glycol mixture have an

impact on valve and pump sizing. All glycol

solutions have a lower specific heat than water.

This means that the glycol solution cannot

transfer heat as well as pure water, resulting in

the need for higher flow rates. In addition, the

viscosity of the glycol solution is usually higher

than water, requiring a higher pump head for the

same given flow. Consult factory for specific

applications, pump selection and flow rate.

e. If this boiler is used in connection with refriger-

ation systems, the boiler must be installed so that

the chilled medium is piped in parallel with the

heating boiler using appropriate valves to prevent

the chilled medium from entering the boiler. See

Figure 53.

Figure 5: Typical Burnham Boiler -

Primary - Secondary Loop System

Figure 5: Recommended Piping for Combination

Heating & Cooling (Refrigeration) Systems

Multiple boilers are installed the same as single

boiler installations. Each boiler loop will contain

its own boiler circulator (see Figure 49b).

The boiler circulator selection will maintain a

constant and minimum flow through the boiler

during every heat demand. The circulator

must be properly selected, based on the design

temperature between the boiler supply and boiler

return. A boiler circulator must be used with a

primary/secondary piping arrangement.