Burnham MPC User Manual

Page 71

71

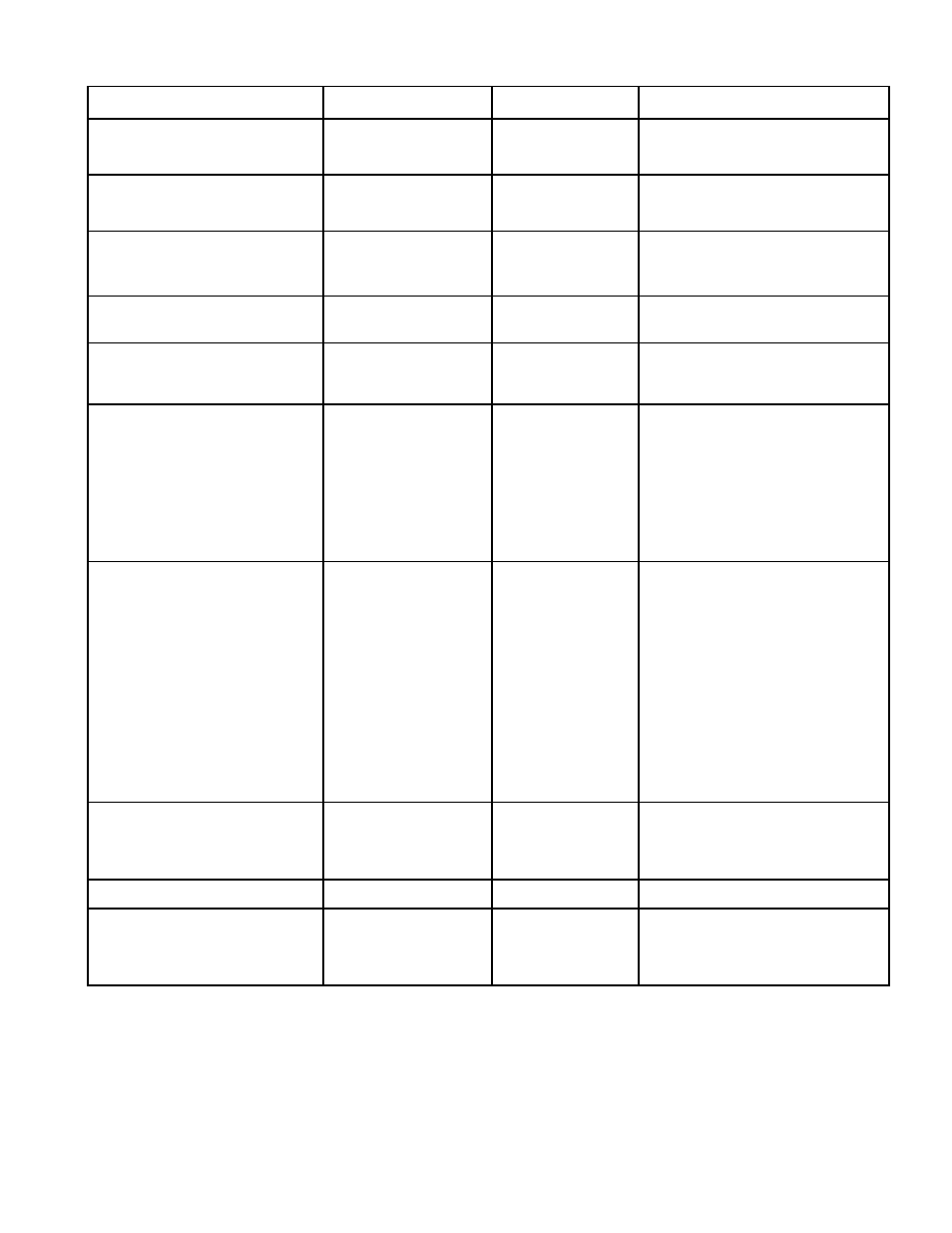

Table XII: Recommended Periodic Testing Check List

Item

Frequency

Accomplished by

Remarks

Gauges and Indicators

Daily

Operator

Make visual inspection and record

readings in log

Instrument and Equipment

Settings

Daily

Operator

Make visual check against

recommended specifications

Firing Rate Control

Weekly

Semiannually

Annually

Operator

Service Technician

Service Technician

Verify factory settings

Verify factory settings

Check with combustion test

Flue, Vent, Stack, or

Outlet Dampers

Monthly

Operator

Make visual inspection of linkage;

Check for proper operation

Igniter

Weekly

Operator

Make visual inspection; Check flame

signal strength if meter-fitted (See

“Combustion Safety Controls”)

Fuel Valves

Pilot and Main

Pilot and Main Gas or Main Oil

Weekly

Annually

Operator

Service Technician

Open limit switch; Make aural and

visual check; Check valve position

indicators and fuel meters, if so

fitted

Perform leakage tests

(Refer to burner instructions)

Combustion Safety Controls

Flame Failure

Flame Signal Strength

Weekly

Weekly

Operator

Operator

Close manual fuel supply for (1)

pilot, (2) main fuel cock, and/or

valve(s); Check safety shutdown

timing; Record in Log

If flame signal meter installed, read

and log; For both pilot and main

flames, notify service organization if

readings are very high, very low, or

fluctuating (Refer to burner instruc-

tions)

Pilot Turndown Tests

As required / annually

Service Technician

Required after any adjustments to

flame scanner mount or pilot burner;

Verify annually (Refer to burner

instructions)

Hot Refractory Hold-In

As required / annually

Service Technician

See “Pilot Turndown Tests”

Low Water Cutoff and Alarm

Daily / Weekly

Semiannually

Operator

Operator

Refer to instructions

Perform a slow drain test in accor-

dance with ASME Boiler and Pres-

sure Vessel Code Section VI

(continued)