Caution – Burnham MPC User Manual

Page 51

51

1. In most cases the burner adapter plate carton for the

specified burner will be provided by Burnham.

2. If adapter is provided by Burnham, open carton

and remove contents. Apply four (4) small dabs

of silastic on rear surface of adapter plate to

temporarily hold gasket in place. Hold adapter plate

in position against burner swing door, align holes

and secure with four (4) 3/8” lock washers and

3/8” - 16 x 7/8” lg. cap screws.

3. If adapter is furnished with burner, follow

manufacturer’s instructions using gasket material

and hardware provided with burner.

4. USE A HOLE SAW OR KNIFE TO CUT BURNER

SWING DOOR INSULATION TO MATCH

HOLE SIZE ON BURNER ADAPTER PLATE.

After cutting, remove any and all loose pieces of

insulation which may become lodged or interfere

with the head of the burner air tube after insertion.

5. Secure burner to adapter plate with four (4) ½” lock

washers and four (4) ½” - 13 hex nuts provided.

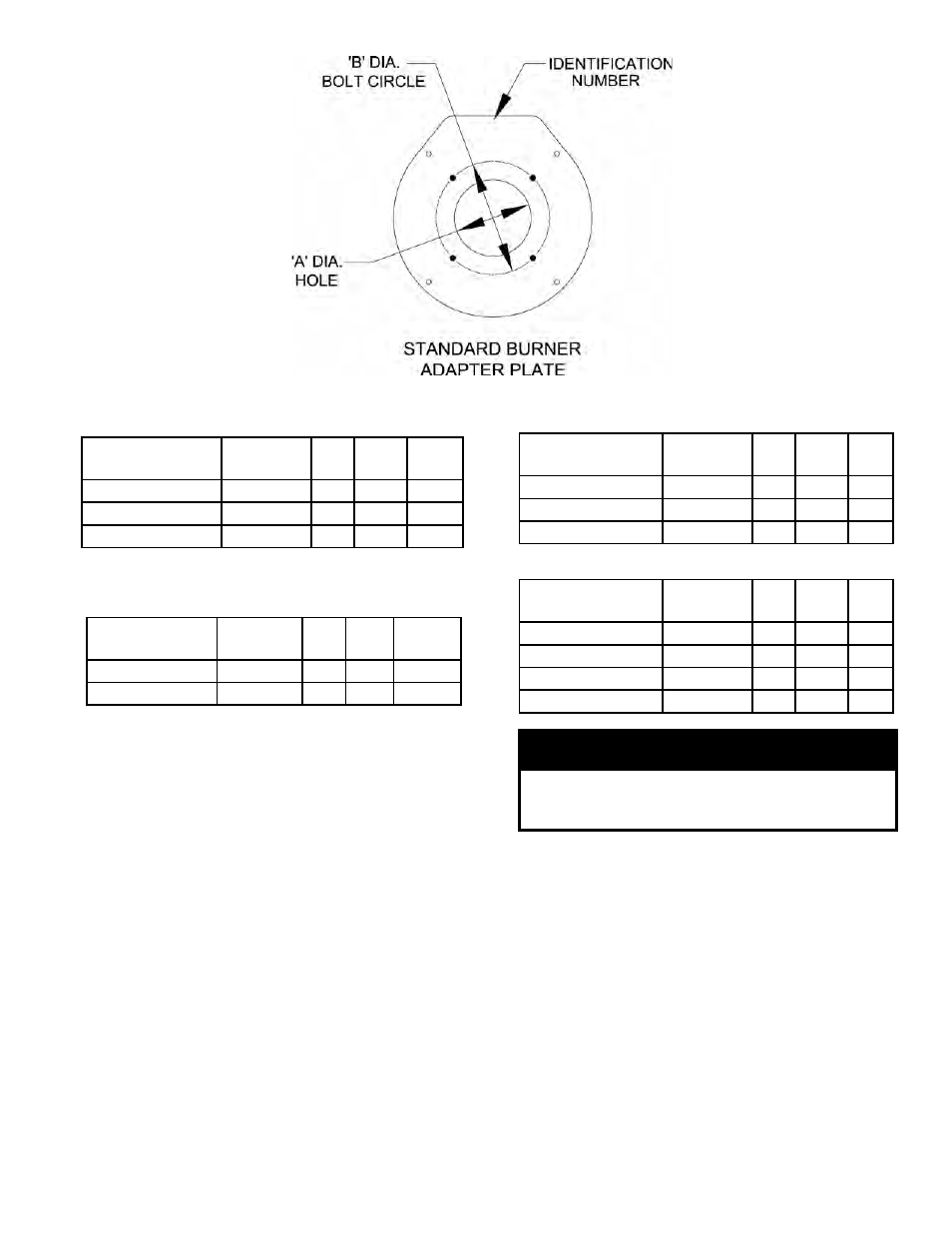

Figure 6: Burner Adapter Plate Options

Boiler Model

Part No.

I.D.

No.

‘A’

‘B’

MPC4 thru MPC7

602263401

40

7-1/2

10-1/4

MPC8 thru MPC14

602263411

41

9

12

MPC15 thru MPC18

602263421

42

10-3/8

14-1/8

Power Flame (‘C’ Series) Burner Adapter Plate

Boiler Model

Part No.

I.D.

No.

‘A’

‘B’

MPC4 thru MPC7

602263451

45

6-3/8

10-1/4

MPC8 thru MPC11

602263461

46

8-3/8

11-11/16

Power Flame (‘JR’ Series) Burner Adapter Plate

Boiler Model

Part No.

I.D.

No.

‘A’

‘B’

MPC4 thru MPC7

602263001

00

6-3/4

10

MPC8 thru MPC15

602263011

01

8-1/4

10

MPC16 thru MPC18

602263021

02

10-1/4

11

Beckett (‘CF’ Series) Burner Adapter Plate

Boiler Model

Part No.

I.D.

No.

‘A’

‘B’

MPC4 and MPC5

602263031

03

5

10

MPC6 and MPC7

602263041

04

6

10

MPC8 thru MPC11

602263071

07

7-1/4

10

MPC12 thru MPC18

602263081

08

8-1/8

11

Beckett (‘CG’ Series) Burner Adapter Plate

CAUTION

Failure to properly fill all gaps between the

insulation and burner blast tube may result in

damage to the burner.

6. Confirm that hole in insulation fits snugly around

burner blast tube. If hole is oversized, open burner

swing door (with burner attached) to access burner

blast tube. Use additional fiberglass rope gasket

provided with burner to fill in any space between

insulation and blast tube. If additional rope gasket

is not provided with the burner, use 3/8” fiberglass

rope rated for 2300°F (provided by others).

When finished, close burner swing door and secure

hardware.

P.

Connect Internal Control / Safety Circuit Wiring

Harness to Burner Controls, see Figures 25 and 37.

Also, refer to Burner Installation Manual and wiring

diagrams provided with burner.