Sioux Chief PEX F2159 User Manual

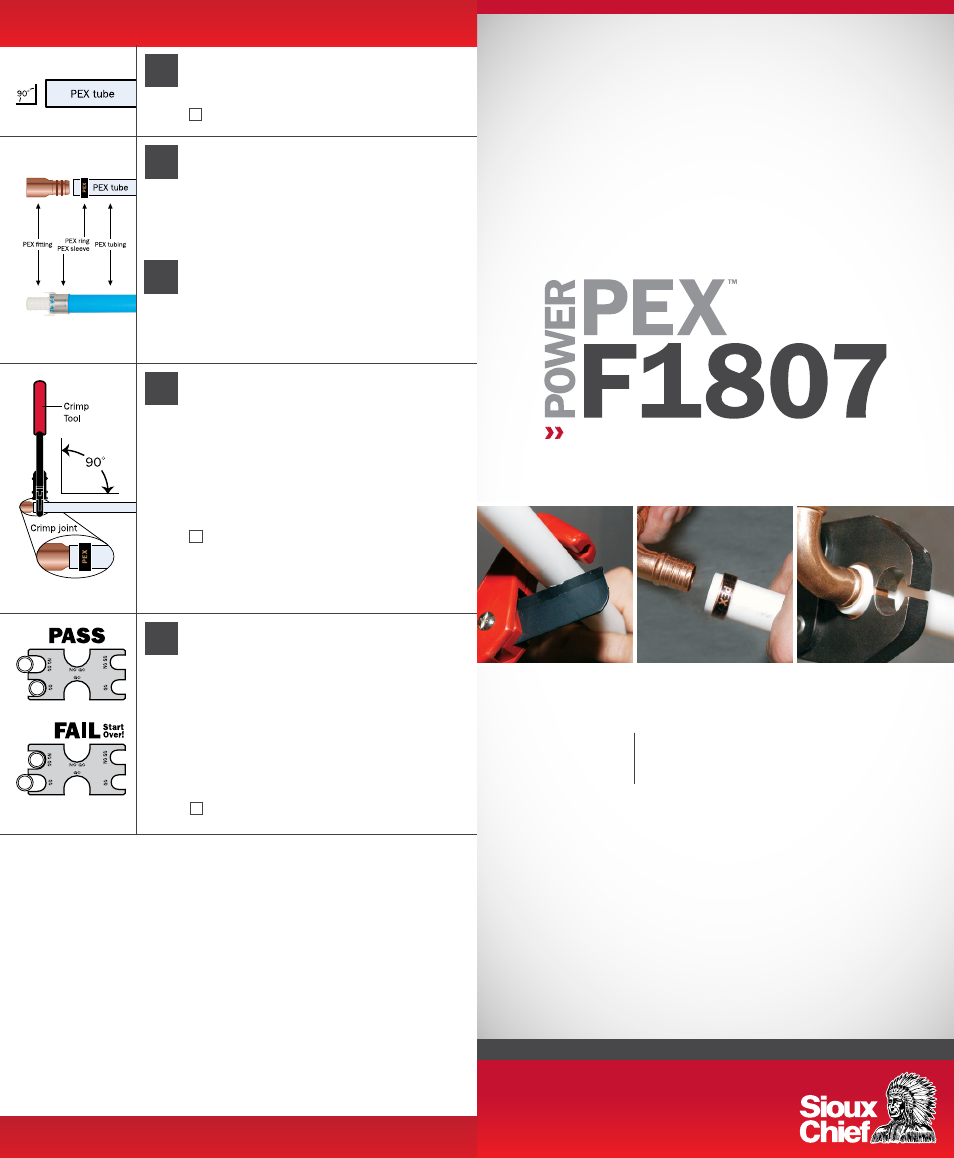

Making crimp connections, 4installation guide

BE SURE TO CHECK EVERY CRIMP

JOINT! Every crimp joint should be

checked with the GO/NO GO Gauge. If

the designated GO slot fits over and will

rotate around the crimped ring, you have

made a proper crimp. If the crimped ring

will fit in the NO GO Gauge or will not fit

in the GO Gauge, you must cut the crimp

joint off and make a new connection.

YOU’LL NEED

GO/NO GO Gauge

Slide the PEX crimp ring over the end

of the PEX tube leaving about ¼″ of the

tube showing. Insert the fitting into the

end of the tube. BE SURE the crimp ring

is centered over the PEX barb.

All of the information you’ll need

to plan and install PEX plumbing

in your home.

Cut tube off square (90°)

with a tube cutter.

YOU’LL NEED

Tube Cutter

More about PEX Crimp Connections

• Can be used with both hot and cold drinking water lines or with

hydronic (radiant) heating.

• Insert fittings can be installed behind walls, but cannot be buried in concrete.

• Use the Home Run system or install in a continuous loop.

• PEX crimp rings are made of annealed copper. Sioux Chief’s PEX V-Sleeve is made

of Stainless Steel.

PEX and PB fittings and crimp rings are not interchangeable.

All Sioux Chief fittings and rings are manufactured to the ASTM Standard F1807

Specification for Metal Insert Fittings Utilizing a Copper Crimp Ring for SDR 9 Cross-

linked Polyethylene (PEX) Tubing, and are compatible with any and all fittings and rings

manufactured to this same standard. All Sioux Chief plastic fittings are made to the

ASTM F2159 specification for plastic insert fittings. Sioux Chief’s V-Sleeve connection is

made to the ASTM F877 standard for hot and cold PEX systems utilizing SDR plastic tubing.

12

PEX INSTALLATION GUIDE – 10/11

© 2011 SIOUX CHIEF MFG.

Note: sleeves and crimp rings are to be used

with either ASTM F1807 or F2159 fittings along

with the appropriate tool.

Center the jaws of the correct size

crimp tool over the crimp ring or sleeve.

Be sure the tool is held STRAIGHT and

close the jaws completely. CRIMP/

PRESS ONE TIME ONLY! If you do not

get a proper crimp connection the first

time, cut the fitting off and start from

the beginning.

YOU’LL NEED

Compression/Crimp Tool

Slide the PEX sleeve over the end of

the PEX tube fully. Insert the fitting into

the end of the tube. BE SURE the fitting

is inserted fully into the pipe.

www.siouxchief.com

Supply

Drainage

Support

12 PEX Installation Tips

Making Crimp Connections

STEP

1

STEP

2

STEP

2

STEP

3

STEP

4

Installation Guide