Filters, 6 filter sizing, 7 membrane dryers – Norgren Filter Contents User Manual

Page 5

Filters

Littleton, CO USA

Phone 303-794-2611

www.norgren.com

ALE-Filter

1.6

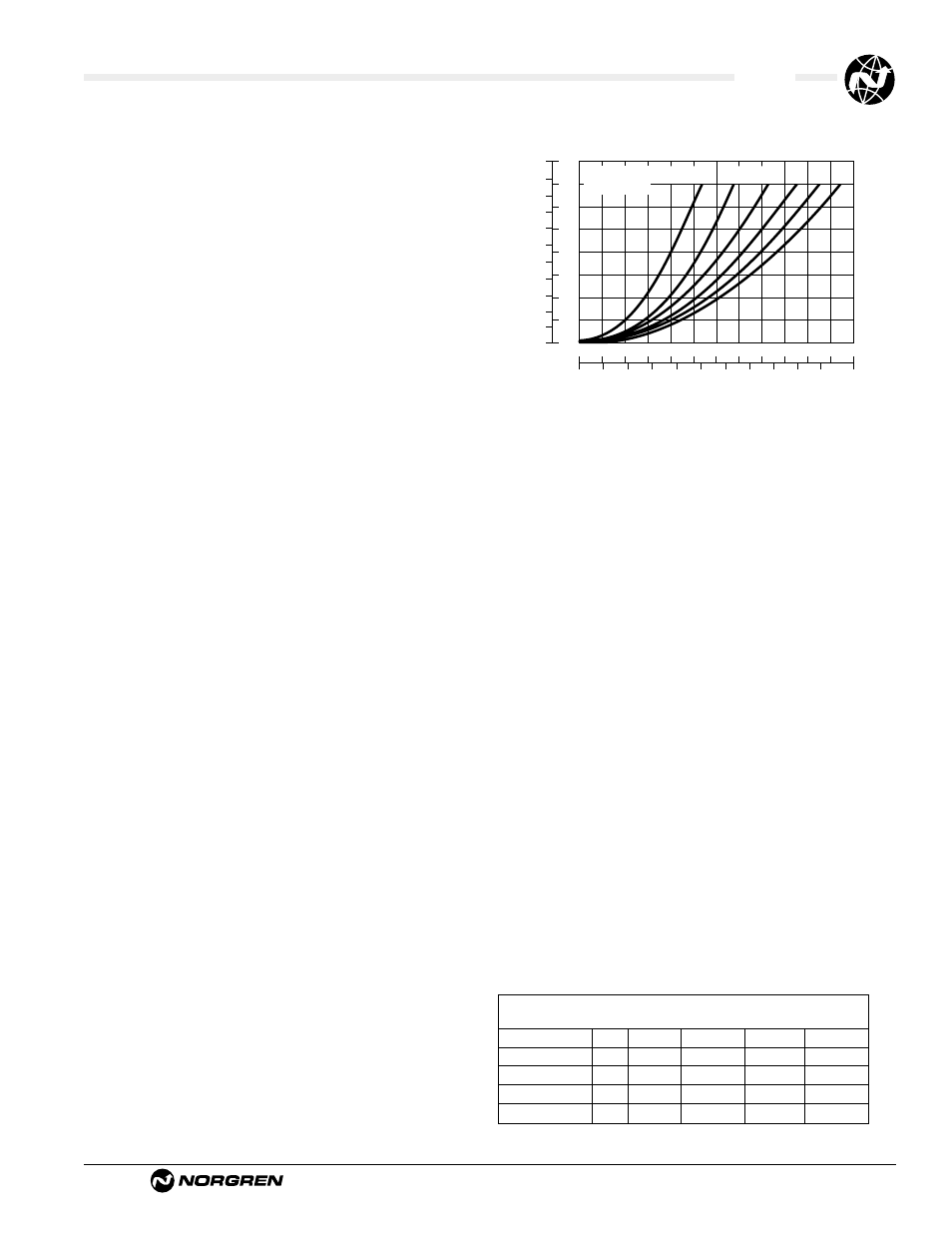

FILTER SIZING

Selecting the proper size of filter for any

application should be done by determining the

maximum allowable pressure drop which can

be caused by the filter. The pressure drop can

be determined by referring to flow curves

provided by the manufacturer.

The flow characteristic curves should relate to

the fluid used, pressure, pipe port size and

micron rating of the filter element. Often the

parameters of pressure and flow are labeled in

metric and imperial units. The vertical axis is

the pressure drop across the filter, and the

horizontal axis is the air flow through the filter.

Each curved line represents the filter flow and

pressure drop characteristics for different

operating pressures.

Example Find the pressure drop across the

filter when operating at 90 psig (6.2 bar) and

when 50 scfm (24 dm

3

/s) is flowing through

the filter.

Answer Locate 50 scfm (24 dm

3

/s) on the

horizontal axis. Read up to the intersecting

point on the 90 psig (6.2 bar)operating curve.

The pressure drop (or

∆

p) is approximately .6

psid (.04bar) on the vertical axis on the left of

the graph. (See graph)

0

0

0

10

20

30

40

50

Air Flow

Flow Characteristics

60

70

80

90

100

20

40

60

80 100 120 140 160 180 200 220 scfm

dm 3/s

0

05

10

15

20

25

30

35

40

45

bar d

psid

1

2

3

4

5

6

7

Pressure Drop

180

(12.5)

150

(10.4)

120

(8.3)

90

(6.2

60

(4.1)

35

(2.4)

psig

(bar)

INLET

PRESSURE

1.7

MEMBRANE DRYERS

For those applications where a low-pressure

dewpoint and low installation/operational cost

are required, Norgren provides an Excelon®

Membrane Dryer. This new product can

provide dewpoint suppression up to 80°F

(26°C) below ambient temperature and is

available with nominal flows of 2, 5, 10, 20,

and 30 scfm.

The Membrane Dryer is a variable dew point

suppression device constructed of an anodized

aluminum body with end caps. Inside the

body are bundles of special hollow fibers

(membranes) which are semi-permeable.

Moisture-laden air enters the fibers and water

vapor permeates through the walls to the

outside of the fibers. Dry air exits the device

through the outlet port. A small percentage of

dry air is diverted across the outside of the

fibers to sweep away and vent water vapor to

atmosphere.

This device provides variable dew point

suppression inversely related to flow. Lower

flows through a unit will increase contact time

with the membrane fibers, resulting in greater

dew point suppression. Higher flows will

result in a decreased level of dew point

suppression. Additionally, dew point

suppression is directly related to operating

pressure. Increasing the pressure applied will

result in a greater level of dew point

suppression. Therefore, it is always

recommend placing regulators downstream of

a membrane dryer to ensure the highest

pressure possible through the membrane dryer.

Model

Port Outlet Inlet Purge Press.

Flow

Flow

Flow

Drop

W07M2ANNNA

1/4" 2 scfm

2.2 scfm 0.2 scfm

0.4 psid

W72M2ANNNB

1/4" 5 scfm

5.6 scfm 0.6 scfm 0.32 psid

W72M2ANNNC

1/4" 10 scfm 11.2 scfm 1.2 scfm 0.90 psid

W74M4ANNND

1/2" 20 scfm 22.2 scfm 2.2 scfm 0.65 psid

W74M4ANNNE

1/2" 30 scfm 33.4 scfm 3.4 scfm 1.35 psid

Typical Flows for Membrane Dryers