F47 oil removal (coalescing) filters, Ale-2-17 technical data, Typical performance characteristics – Norgren Filter Contents User Manual

Page 41: Service kits

F47 Oil Removal (Coalescing) Filters

Littleton, CO USA

Phone 303-794-2611

www.norgren.com

ALE-2-17

Technical Data

Fluid: Compressed air

Maximum pressure: 250 psig (17 bar)

Operating temperature:* -30° to 150°F (-34° to 65°C)

* Air supply must be dry enough to avoid ice formation at temperatures below 35°F (2°C).

Particle removal: Down to 0.01 µm

Air quality: Within ISO 8573-1, Class 1 (particulates) and Class 2 (oil content)

Maximum remaining oil content in outlet air: 0.01 ppm at 70°F (20°C) with an inlet

concentration of 17 ppm

Maximum flow for oil-saturated element at 90 psig (6.3 bar) inlet pressure to

maintain stated oil removal performance

1-1/2" Ports: 250 scfm (118 dm

3

/s)

2" Ports: 300 scfm (142 dm

3

/s)

2" Ports, high flow element: 600 scfm (283 dm

3

/s)

Typical flow for dry element at 90 psig (6.3 bar) inlet pressure and 5 psid (0.3 bar)

pressure drop

1-1/2" Ports: 780 scfm (368 dm

3

/s)

2" Ports: 830 scfm (392 dm

3

/s)

2" Ports, high flow element: 2300 scfm (1086 dm

3

/s)

Nominal bowl size: 7 fluid ounce (0.2 liter)

Manual drain connection: Will fit 1/8-27 and 1/8-28 pipe thread.

Automatic drain connection: Will fit 1/8-27 and 1/8-28 pipe thread. - Flexible tube

with 3/16" (5mm) minimum I.D. can be connected to the automatic drain. Drain

may fail to operate if the tube I.D. is less than 3/16" (5mm). Avoid restrictions in

the tube.

Automatic drain operating conditions (float operated)

Bowl pressure required to close drain: Greater than 5 psig (0.3 bar)

Bowl pressure required to open drain: Less than 3 psig (0.2 bar)

Minimum air flow required to close drain: 2 scfm (1 dm

3

/s)

Manual operation: Depress pin inside drain outlet to drain bowl

Materials

Body, intermediate body, bowl: Aluminum

Metal bowl liquid level indicator lens: Transparent nylon

Filter element: Synthetic fiber and polyurethane foam

Elastomers: Neoprene and nitrile

Service indicator

Body: Transparent nylon

Internal parts: Acetal

Spring: Stainless steel

Elastomers: Nitrile

An automatic drain is a two-way valve, which will close

when the system is pressurized. The drain opens

when the float rises due to accumulated liquid and

on depressurization.

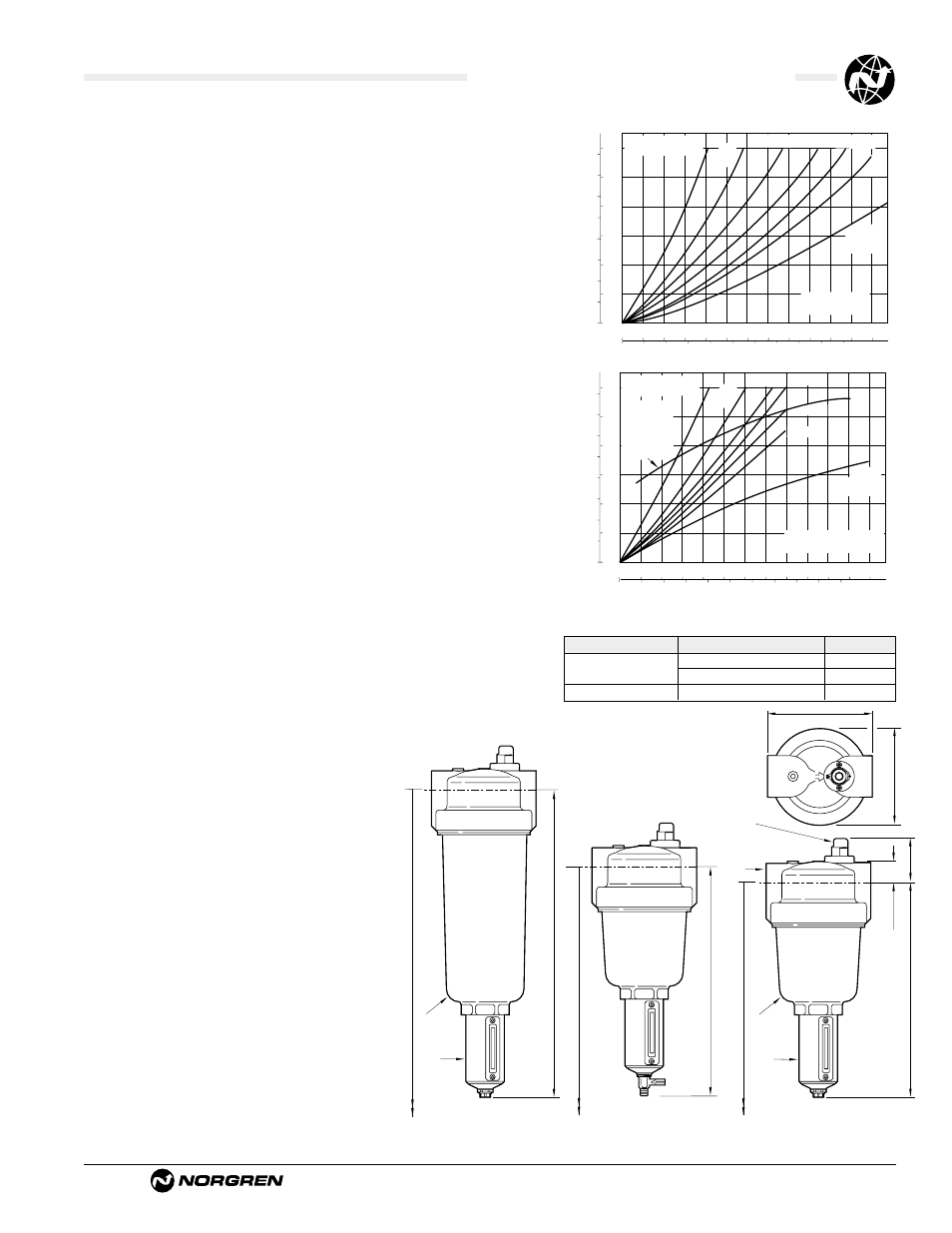

0.3

0.2

0.1

0

PRESSURE DROP

5

4

3

2

1

0

psid

bar d

PORT SIZE: 2"

ELEMENT: SATURATED

0 50 100 150 200 250

dm

3

/s

AIR FLOW

0 100 200 300 400 500

scfm

36

(2.5)

58

(4.0)

INLET PRESSURE:

psig (bar g)

116 (8.0)

150 (10.0)

90 (6.3)

High Flow

Element

90 (6.3)

175 (12.0)

Maximum

flow to

maintain

stated oil

removal

performance

PRESSURE DROP

0.15

0.10

0.05

0

bar d

2.5

2.0

1.5

1.0

0.5

0

psid

PORT SIZE: 2"

ELEMENT: DRY

0 100 200 300 400 500

dm

3

/s

AIR FLOW

0 200 400 600 800 1000

scfm

58

(4.0)

INLET PRESSURE:

psig (bar g)

116 (8.0) 150 (10.0)

90 (6.3)

High Flow

Element

90 (6.3)

36

(2.5)

175

(12)

Typical Performance Characteristics

8.16 (207)

8.22 (209)

15.70 (399)

1/4 Turn Manual Drain

23.58 (599)

†

23.55 (598)**

High Flow Filter

with Automatic Drain

39.25 (997) **

15.10 (384)

1.86 (47)

3.16 (80)

Automatic Drain

22.99 (584)

†

Service

Indicator

Intermediate

Body

Bowl

Intermediate

Body

Bowl

Body

**

Minimum clearance required to remove intermediate body and bowl. Add 0.59" (15 mm) for 1/4 turn manual drain.

†

Minimum clearance required to remove intermediate body and bowl.

All Dimensions in Inches (mm)

Service Kits

Item

Type

Part number

Element kit

Standard

3203-02

High flow

3203-05

Sightglass kit

All

2273-08