F72c oil removal (coalescing) filters, Ale-2-5, Service kits – Norgren Filter Contents User Manual

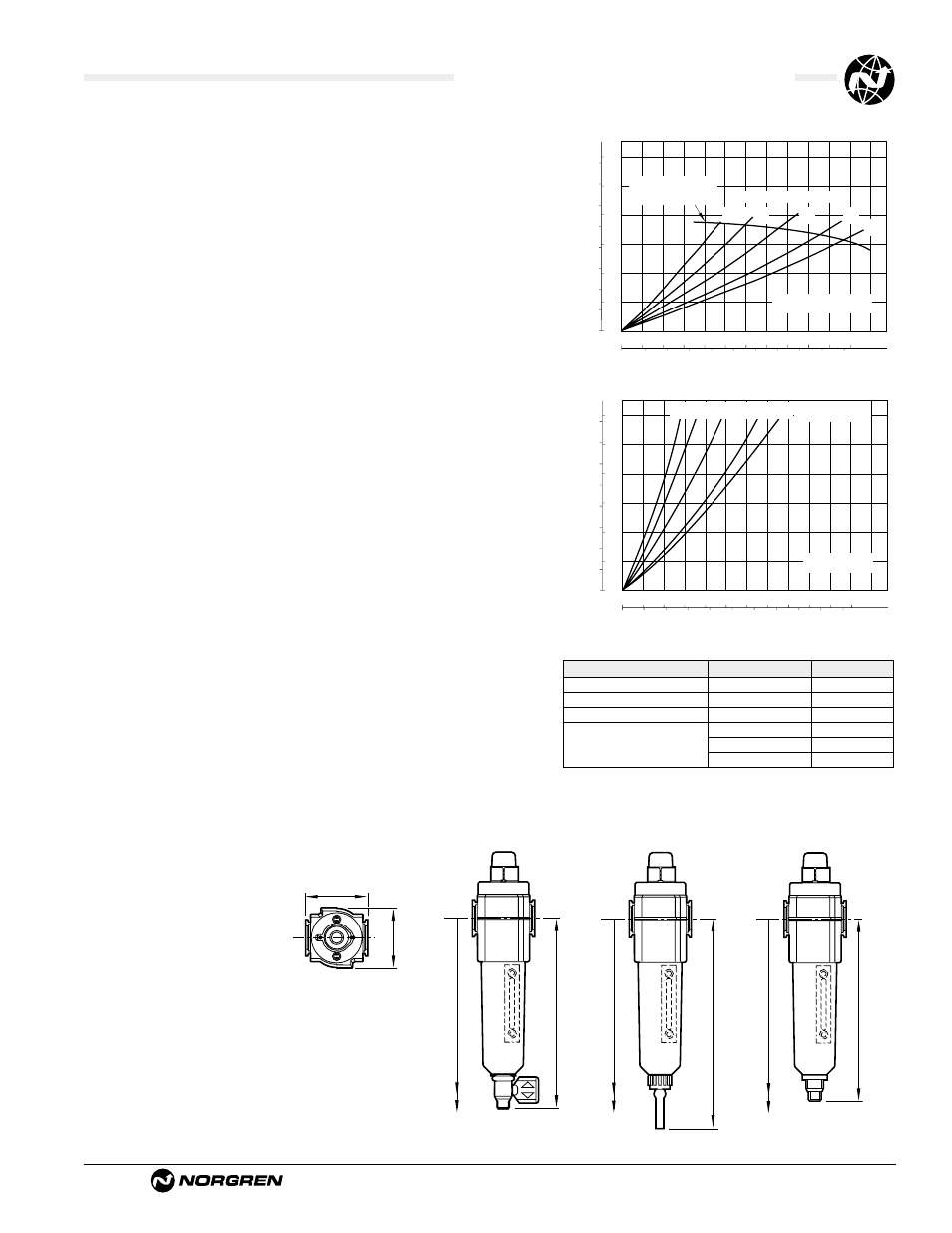

Page 29: Technical data, Typical performance characteristics

F72C Oil Removal (Coalescing) Filters

Littleton, CO USA

Phone 303-794-2611

www.norgren.com

ALE-2-5

PORT SIZE: 1/4"

SATURATED ELEMENT

INLET PRESSURE: psig (bar)

FLOW CHARACTERISTICS

0 1 2 3 4 5

dm

3

/s

AIR FLOW

0 2 4 6 8 10 scfm

0.4

0.3

0.2

0.1

0

PRESSURE DROP

bar d

5

4

3

2

1

0

psid

36

(2.5)

23

(1.6)

58

(4.0)

91

(6.3)

116

(8.0)

Maximum flow to

maintain stated oil

removal performance

1.97 (50)

1.89 (48)

Bowl with

Automatic Drain

5.51 (140)

7.52 (191)

†

Bowl with

Semi auto Drain

7.48 (190)

9.84 (250)

†

Bowl with

1/4 Turn Manual Drain

5.83 (148)

7.83 (199)

†

(Top)

†

Minimum clearance required to remove bowl.

Service Kits

Item

Type

Part Number

Service kit

Seal and gasket

4380-500

Element

Coalescing

5925-09

Liquid level lens kit

Prismatic

4380-030

1/4 turn manual

619-50

Replacement drains

Semi automatic

5379-RK

Automatic 4000-50R

Service kit includes bowl o-rings.

Technical Data

Fluid: Compressed air

Maximum pressure:

Transparent bowl: Manual or semi automatic drain: 150 psig (10 bar)

Automatic drain: 116 psig (8 bar)

Metal bowl: Manual or semi automatic drain: 250 psig (17 bar)

Automatic drain: 116 psig (8 bar)

Operating temperature*: Transparent bowl: -30° to 125°F (-34° to 50°C)

Metal bowl: -30° to 150°F (-34° to 65°C)

* Air supply must be dry enough to avoid ice formation at temperatures below 35°F (2°C).

Particle removal: 0.01 µm

Air quality: Within ISO 8573-1, Class 1 (particulates) and Class 2 (oil content)

Maximum remaining oil content in outlet air:

0.01 ppm at 70°F (21°C) with an inlet concentration of 17 ppm.

Maximum flow with 90 psig (6.3 bar) inlet pressure**: 9.5 scfm (4.5 dm

3

/s)

** Maximum flow to maintain stated oil removal performance.

Manual drain connection: Will fit 1/8-27 and 1/8-28 pipe thread.

Semi automatic drain connection: Push on 5/16" (8 mm) ID tube

Semi automatic drain operating conditions (pressure operated):

Bowl pressure required to close drain: Greater than 1.5 psig (0.1 bar)

Bowl pressure required to open drain: Less than 1.5 psig (0.1 bar)

Minimum air flow required to close drain: 1 scfm (0.5 dm

3

/s)

Manual operation: Lift stem to drain bowl

Automatic drain connection: Will fit 1/8-27 and 1/8-28 pipe thread. - Flexible tube

with 3/16" (5mm) minimum I.D. can be connected to the automatic drain. Drain

may fail to operate if the tube I.D. is less than 3/16" (5mm). Avoid restrictions in

the tube.

Automatic drain operating conditions (float operated):

Bowl pressure required to close drain: Greater than 5 psig (0.3 bar)

Bowl pressure required to open drain: Less than 3 psig (0.2 bar)

Minimum air flow required to close drain: 0.2 scfm (0.1 dm

3

/s)

Manual operation: Depress pin inside drain outlet to drain bowl

Nominal bowl size

Long bowl: 2.2 fluid ounce (65 ml)

Materials

Body: Zinc

Bowl

Transparent: Polycarbonate

Guard for transparent bowl: Zinc

Metal: Zinc

Metal bowl liquid level indicator lens: Transparent nylon

Element: Synthetic fiber and polyurethane foam

Elastomers: Neoprene and nitrile

Service life indicator

Body: transparent nylon.

Internal parts: acetal.

Spring: stainless steel.

Elastomers nitrile

An automatic drain is a two-way valve, which will close when the system is

pressurized. The drain opens when the float rises due to accumulated liquid

and on depressurization.

PORT SIZE: 1/4"

DRY ELEMENT

INLET PRESSURE:

psig (bar)

FLOW CHARACTERISTICS

0 4 8 12 16 20

dm

3

/s

0 8 16 24 32 40 scfm

0.4

0.3

0.2

0.1

0

PRESSURE DROP

bar d

5

4

3

2

1

0

psid

36

(2.5)

23

(1.6)

58

(4.0)

91

(6.3)

116

(8.0)

Typical Performance Characteristics

All Dimensions in Inches (mm)