Filters, 1 general overview, 2 air quality – Norgren Filter Contents User Manual

Page 2

Filters

Littleton, CO USA

Phone 303-794-2611

www.norgren.com

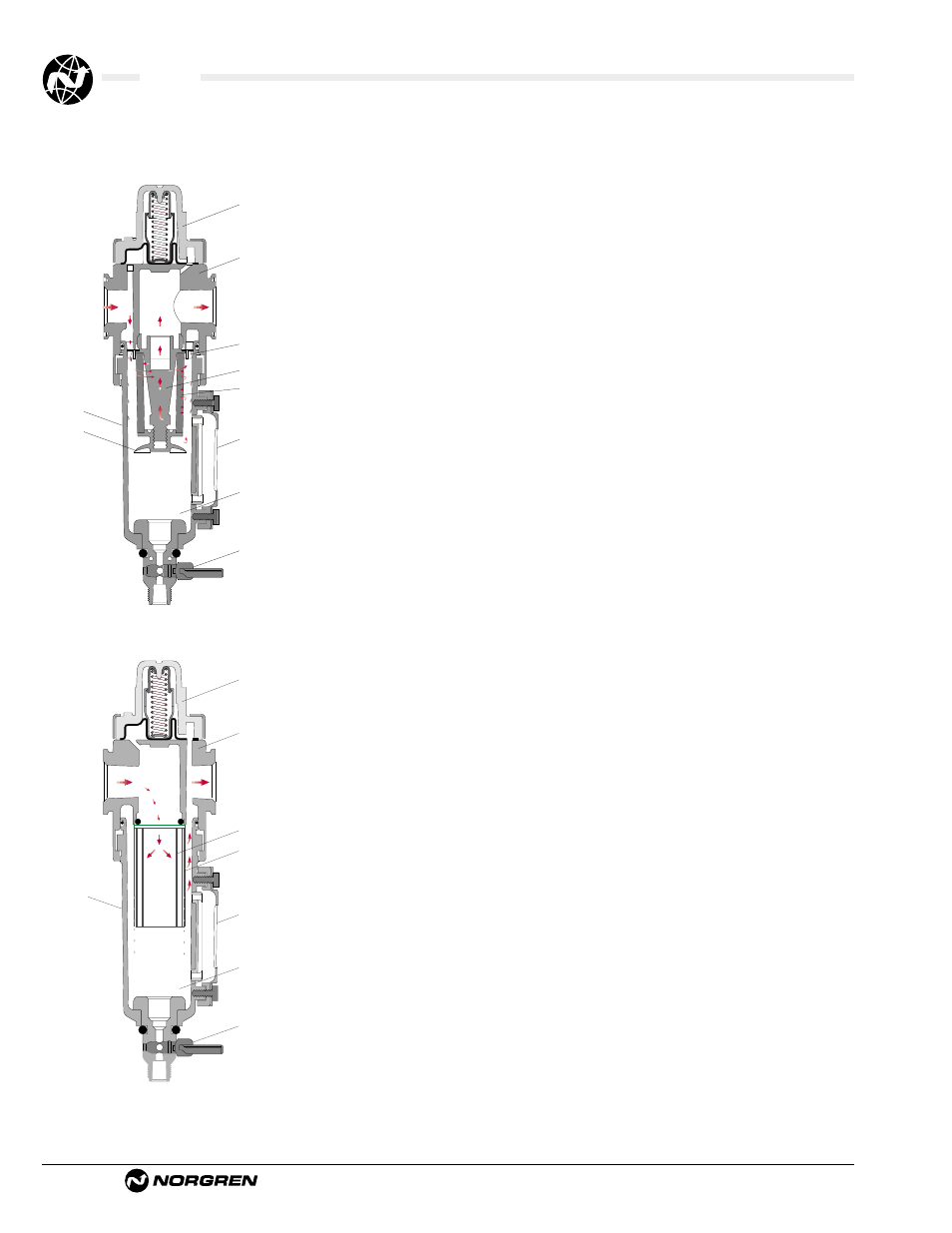

ALE-Filter

GENERAL PURPOSE FILTER

COALESCING FILTER

;;;

;;;

;;;

;;;

;;;

;;;

;;;

yyy

yyy

yyy

yyy

yyy

yyy

yyy

Service indicator

(optional)

Body

Centre post

Element

Metal bowl

sight glass

Collected

condensate

Drain

Louvre

Baffle

Bowl

;;;

;;;

;;;

;;;

;;;

;;;

;;;

yyy

yyy

yyy

yyy

yyy

yyy

yyy

Service indicator

Body

Element

Outer sock

Metal bowl

sight glass

Collected

condensate

Drain

Bowl

1.1

GENERAL OVERVIEW

Three main types of filters exist: The general

purpose filter for water and particles, the coalescing

oil removal filter for oil aerosols and the activated

carbon filter for the removal of oil vapors.

The general purpose filter is used for most

filter applications and is available from 1/8" to 2"

pipe sizes. Uses are main headers, branch lines,

tools, cylinders, valves and valve circuits, air

agitators etc. Oil removal filters are used where very

clean, oil-free air is required, such as for the supply

to fluidic devices, instrumentation, air gauging

equipment and air bearings.

Activated Carbon filters are used for

systems where the oil vapors in the air are not

acceptable; such as instrumentation and paint

spraying.

1.1.1

How Do General Purpose Filters Work?

The dirt and moisture-laden air enters the inlet port

and is directed into the louvers which centrifugally

separate the entrained liquids and dirt which fall to

the bottom of the bowl. Near the bottom of the bowl

a baffle creates a quiet zone, preventing the

turbulent air re-entraining the contaminants. The air,

now free of water droplets and large dirt particles,

passes through the filter element which removes

small dirt particles. Solid particles eventually plug

the element necessitating replacement.

1.1.2

How Do Oil Removal Filters Work?

Air enters the filter and passes through the

element from inside to outside, where oil aerosols

impinge on the borosilicate micro-fibers and are

coalesced into larger drops. The drops are carried

through the element until they reach the outer

porous sock. The outer sock, because of its cellular

construction, retains these liquids and allows them

to drain by gravity to the bottom of the bowl.

Solid partilces are retained in the element

and cause the pressure drop to slowly increase

throught the working life of the element. When the

pressure drop across the element reaches 10 psid,

the service life indicator on top of the filter will

show more red than green and the element should

be replaced.

1.1.3

How do Vapor removal Filters Work?

Carbon filters are used to remove oil vapors and

odors. The activated carbon has a porous structure

which results in a large surface area. The oil vapors

are attracted and adhere to this surface. There is

usually a small sintered medium included in an

activated carbon element to prevent the carbon

particles from migrating downstream. The carbon

filter reduces the maximum oil content of air leaving

the filter to 0.003ppm at 70°F, i.e. To ISO 8573 class

1.7.1. If protected upstream by general and oil

removal filters life is between 400 and 1000 hours.

1.1.4 Why use a Pre-Filter?

A pre-filter is simply a general purpose filter placed

upstream of a higher grade filter to remove the

majority of the water and larger particle

contaminants and thus lengthen the life of the higher

grade filter element.

A 5 micron pre-filter should always be used

ahead of an oil removal filter.

An oil removal (coalescing) filter must be

used ahead of a vapor removal adsorbing filter.

1.2

AIR QUALITY

1.2.1

What is ISO 8573?

(See ALE-1-G for specification)

This is an international standard on air quality. It

covers compressed air for general industrial use.

The air quality is specified using a 3 digit

code expressing the remaining content of a specific

contaminant after the filter (or dryer).

1.2.2

Air Classes for Norgren Filters:

Particulate filters condition compressed air to

different degrees, dependent on the micron rating of

the filter. The finer filter, 5 µm, will achieve ISO 8573

class 3.7. or class 3. Applying a 40 µm filter will

result in ISO 8573 class 5.7. or class 5 air.

Coalescing filters improve the quality of

downstream air to ISO 8573 class 1.7.2, the particle

size is reduced down to 0.01µm, with a remaining

oil content of less than 0.01ppm. Coalescing filters

cannot remove oil which is in the vapor state in the

supply air. One way to remove vapor is to reduce the

temperature of the air flow allowing the vapor to

condense, alternatively remove the vapor chemically

using an activated carbon filter.