Goulds Pumps 3296 EZMAG - IOM User Manual

Page 92

Other Relevant Documentation or Manuals

• Broken or damaged coupling

• Jammed impeller

• Bad bearings

• Rapid cycling

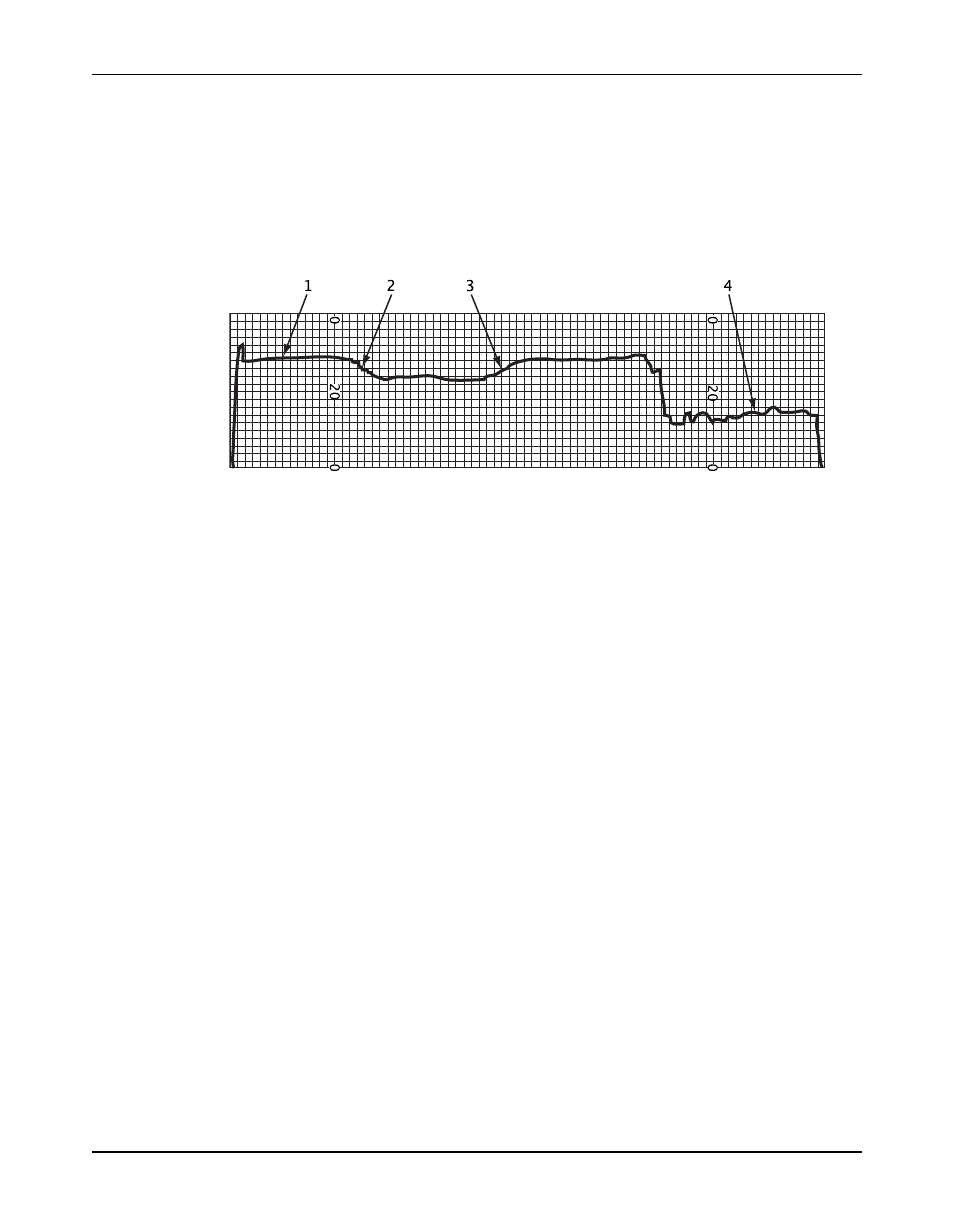

The power draw at each of these conditions can be simulated in a plant test or estimated

through calculations or interpolations from the pump performance curve. By defining these

dangerous power fluctuations, appropriate calibration of the power-monitoring unit prevents

avoidable pump failures. This figure shows a typical power evaluation recorded from a common

centrifugal pump electric motor.

1. The pump is in operation.

2. The valve is closing.

3. The valve is opening.

4. There is no fluid being pumped.

Figure 16: Typical power evaluation

Contact your ITT representative for assistance and power analysis for your specific system. For

further details and evaluation of power monitoring units, a comprehensive power monitor user

guide is available from ITT.

Calibration tips

Use these tips to assist you when you select and calibrate power monitors:

• Read your power monitor installation instructions and wiring diagram before you attempt to

calibrate the unit.

• Understand the recommended operating envelope of your pump provided by ITT.

• Understand the requirements and limitations of your system.

• Understand the full range of your operating duty, including power requirements at the rated

minimum and maximum flow conditions.

• Identify potential failures that would be characteristic of your specific process and pump

type.

• Understand the power scope and torque scope of the selected electric motor.

• When feasible, further define your operating range to run as close to best efficiency point

(BEP) as practical.

• Select either a single trip unit or dual trip unit as practical for your specific system. A dual

trip unit is recommended for the 3296 EZMAG. Always use a low setting in order to protect

against dry run. A high setting detects if an upset condition has occurred. This results in

bearing damage.

• Set a low-power trip point at the required power draw when operation is at the

recommended minimum flow of the manufacturer or higher, but less that the normal

operating point.

• Set a high-power trip point at the required power draw when operation is at the

recommended maximum flow of the manufacturer or lower, or at the flow rate that will

prevent cavitation.

90

Model 3296 EZMAG Installation, Operation, and Maintenance Manual