Suction-piping checklist – Goulds Pumps 3296 EZMAG - IOM User Manual

Page 30

Installation

Checklist

Check

Explanation/comment

Checked

Check that all piping is supported This helps to prevent:

independently of, and lined up

• Strain on the pump

naturally with, the pump flange.

• Misalignment between the pump and the drive unit

• Wear on the pump bearings, seal, and shafting

Keep the piping as short as pos-

This helps to minimize friction losses.

sible.

Check that only necessary fittings This helps to minimize friction losses.

are used.

Do not connect the piping to the

—

pump until:

• The grout for the baseplate or

sub-base becomes hard.

• The hold-down bolts for the

pump and the driver are tight-

ened.

Make sure that all the piping joints This prevents air from entering the piping system or

and fittings are airtight.

leaks that occur during operation.

If the pump handles corrosive

fluids, make sure that the piping

allows you to flush out the liquid

before you remove the pump.

If the pump handles liquids at

This helps to prevent misalignment due to linear expan-

elevated temperatures, make

sion of the piping.

sure that the expansion loops and

joints are properly installed.

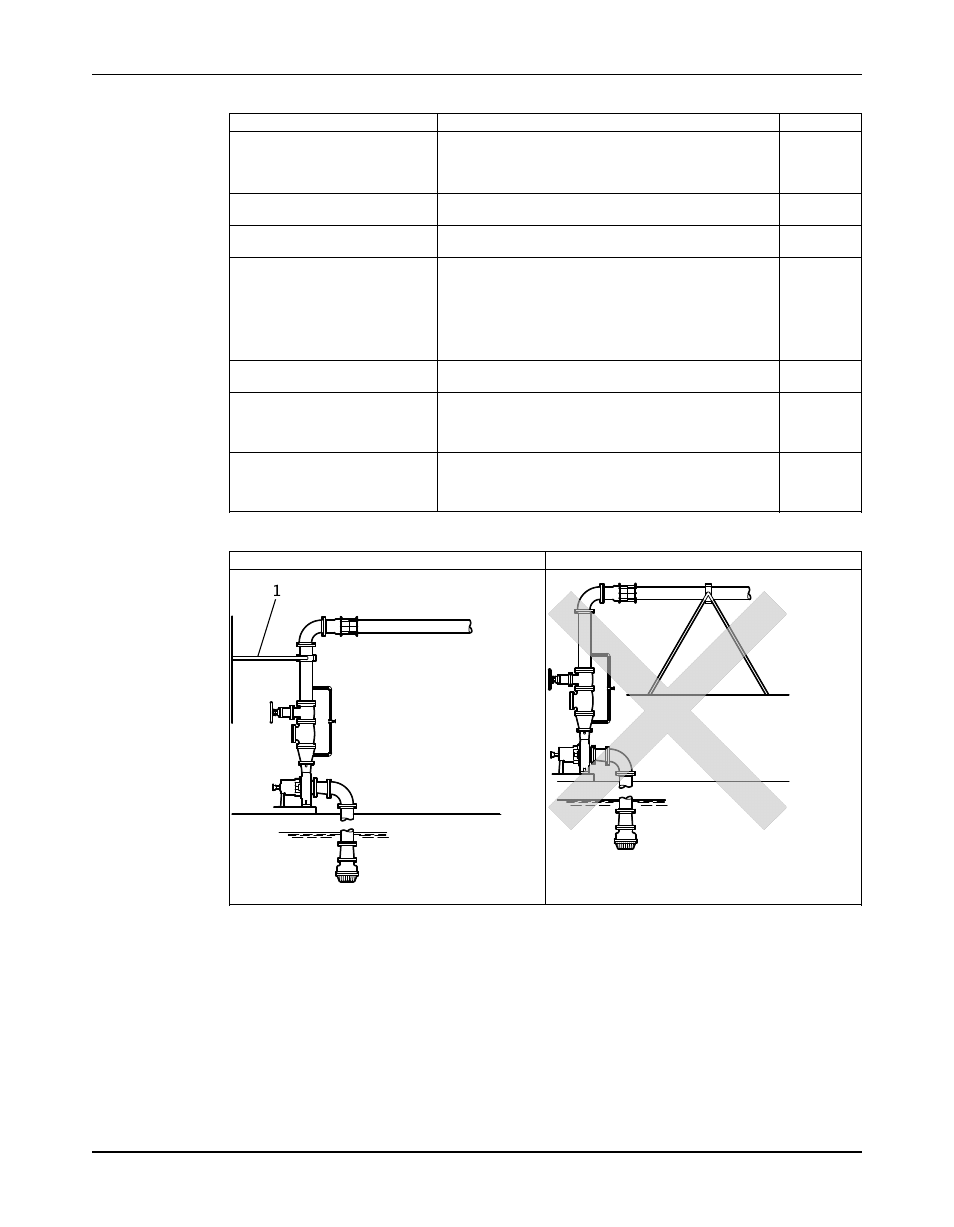

Example: Installation for expansion

Correct

Incorrect

1.

Expansion loop/joint

Suction-piping checklist

Performance curve reference

Net positive suction head available (NPSH

A

) must always exceed NPSH required (NPSH

R

) as

shown on the published performance curve of the pump.

Refer to the Hydraulic Institute for NPSH and pipe friction values needed in order to evaluate

suction piping.

28

Model 3296 EZMAG Installation, Operation, and Maintenance Manual