Goulds Pumps 3296 EZMAG - IOM User Manual

Page 71

Maintenance

b) Mount the impeller (101) onto the shaft.

c) Insert the impeller nut O-ring (412A) into the groove on the rear side of the impeller nut

(304).

d) Secure the driven magnet assembly with a strap wrench and tighten the impeller nut to

the appropriate torque value.

See

NOTICE:

Check that you can rotate the backplate freely by hand. When you raise the backplate,

make sure that the axial play is approximately 0.040 in. (1.02 mm) in order to ensure

proper assembly. The axial play of the plain bearings is automatically set during

assembly.

10. Place the containment shell gasket (540N) and containment shell (750) onto the backplate

(444).

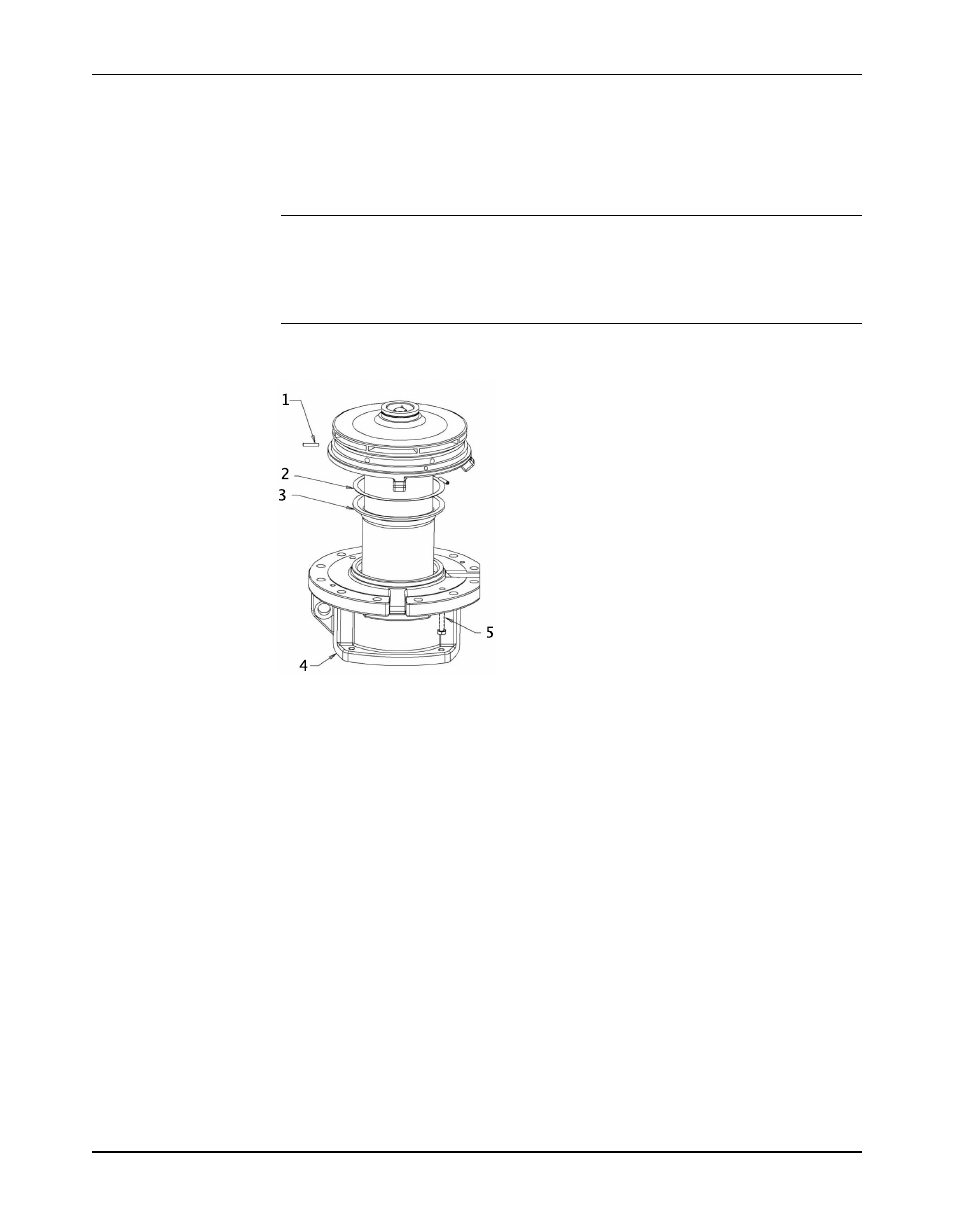

1. Adapter-to-backplate setscrew (222E, 6 in. S-group, 3 x 4-7, and 3 x 4-8G)

2. Containment shell gasket (540N)

3. Containment shell (750)

4. Frame adapter (108)

5. Adapter-to-backplate hex screw (370V)

11. Screw the three setscrews (222E for the 6 in. S-group, 3 x 4-7, and 3 x 4-8G pumps) or two

connection screws (370V for M-group pumps) of the adapter (108) into the backplate and

tighten.

This holds the containment shell in place.

Model 3296 EZMAG Installation, Operation, and Maintenance Manual

69