Goulds Pumps 3296 EZMAG - IOM User Manual

Page 70

Maintenance

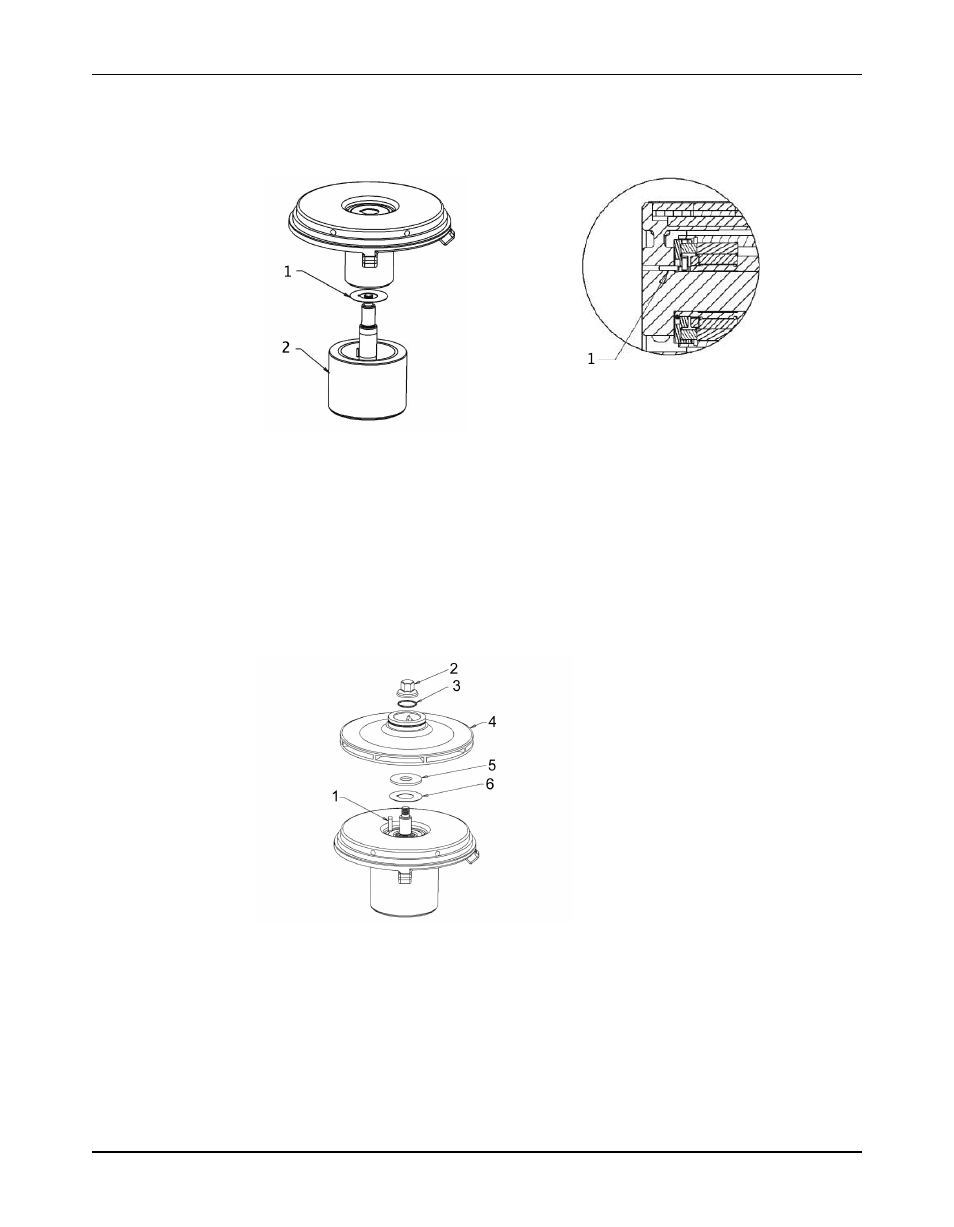

6. Mount the intermediate ring gasket (351X) onto the shaft of the driven magnet assembly

(740A).

Intermediate ring gasket mounting

Driven pin aligned with the slot in the

cartridge

1.

Driven carrier pin (445A)

1.

Intermediate ring spacer (351X)

2.

Driven carrier assembly (740A)

7. Place the driven magnet assembly (740A) on the workbench, and then mount the pre-

assembled bearing cartridge (849) and backplate (444) assembly onto the driven magnet

assembly from above. Make sure the driven carrier pin or key (445A) engages the carrier

groove in the bearing cartridge (849).

If the pin or key at the bottom of the shaft does not properly engage the slot in the bearing

cartridge, then the impeller key in step 9 will not fit.

You can turn the backplate slightly in order to help with alignment.

8. Mount the second intermediate ring gasket (351X) and distance washer (199) onto the

drive shaft.

1. Impeller key (178)

2. Impeller nut (304)

3. Impeller nut O-ring (412A)

4. Impeller (101)

5. Distance washer (199)

6. Intermediate ring spacer (351X)

9. Install the impeller:

a) Insert the impeller key (178) into the key-slot on the shaft.

If the impeller key does not fit into the keyway due to interference with the distance

washer, then go back to step 7 and re-assemble the bearing cartridge to the shaft.

68

Model 3296 EZMAG Installation, Operation, and Maintenance Manual