Goulds Pumps 3296 EZMAG - IOM User Manual

Page 64

Maintenance

NOTICE:

There are several methods you can use to install bearings. The recommended method is to

use an induction heater that heats and demagnetizes the bearings.

Only use original spare parts to replace any worn or faulty components. The use of

unsuitable spare parts may cause malfunctions, damage, and injuries as well as void the

guarantee.

Do not use a flame to heat bearings. This will damage the bearing surfaces. Do not heat the

bearings above 275°F (135°C).

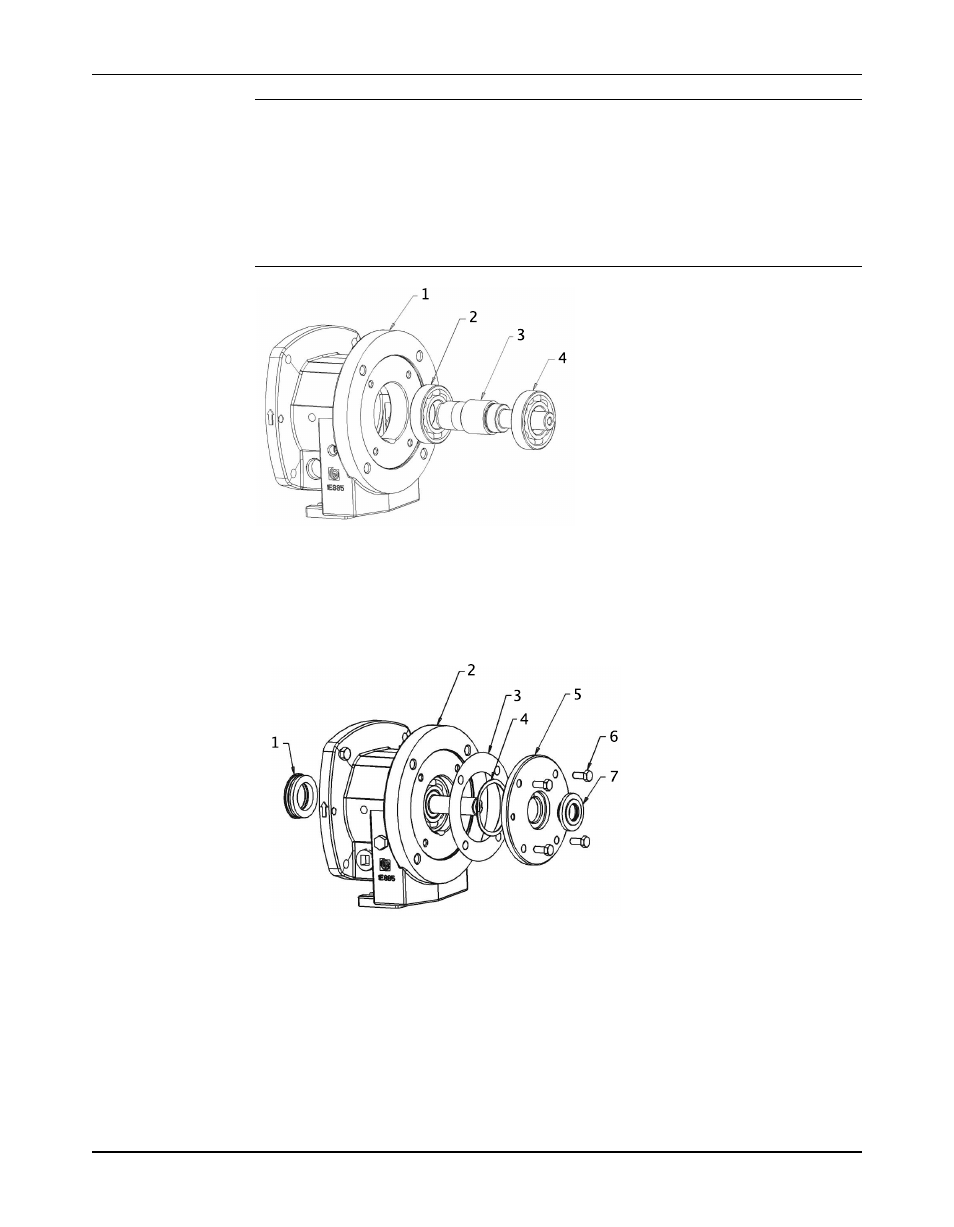

1. Bearing frame (228)

2. Ball bearing (112)

3. Drive shaft (122B)

4. Ball bearing (112)

2. Install the pre-assembled drive shaft in the bearing frame (228) from the motor side.

3. Insert the wave washer (529).

1. Labyrinth oil seal (333)

2. Bearing frame (228)

3. End cover gasket (360A)

4. Wave washer (529)

5. Frame end cover (109A)

6. End cover hex screw (370C)

7. Labyrinth oil seal (332A)

Figure 10: Bearing frame cover and seals

62

Model 3296 EZMAG Installation, Operation, and Maintenance Manual

- 3100 - IOM (52 pages)

- 3171 - IOM (60 pages)

- 3180-86 - IOM (158 pages)

- 3189 - IOM (32 pages)

- 3196 - IOM (148 pages)

- 3196 i-FRAME - IOM (152 pages)

- 3198 i-FRAME - IOM (126 pages)

- 3296M - IOM (92 pages)

- 3298 - IOM (120 pages)

- 3311 - IOM (44 pages)

- 3316 - IOM (36 pages)

- 3335 - IOM (40 pages)

- 3355 - IOM (66 pages)

- 3393 - IOM (124 pages)

- 3408 - IOM (78 pages)

- 3408A - IOM (44 pages)

- 3409 - IOM (68 pages)

- 3410 - IOM (56 pages)

- 3420 - IOM (120 pages)

- 3498 - IOM (59 pages)

- 3500XD - IOM (44 pages)

- 3501 Mixer - IOM (48 pages)

- 3600 - IOM (110 pages)

- 3610 - IOM (98 pages)

- 3620 - IOM (98 pages)

- 3640 - IOM (98 pages)

- 3642 - IOM (12 pages)

- 3675 - IOM (12 pages)

- 3700 - IOM (110 pages)

- 3755 - IOM (32 pages)

- 3796 i-FRAME - IOM (134 pages)

- 3910 11th ed. - IOM (80 pages)

- 3935 - IOM (24 pages)

- 3996 - IOM (52 pages)

- 4550 - IOM (36 pages)

- 5000 - IOM (24 pages)

- 5100 - IOM (28 pages)

- 5150 - IOM (28 pages)

- 7200CB - IOM (132 pages)

- ANSI FAMILY IOM (ATEX Compliant) (56 pages)

- ANSI FAMILY IOM (ATEX Compliant) (27 pages)

- ANSI FAMILY IOM (ATEX Compliant) (42 pages)

- ANSI FAMILY IOM (ATEX Compliant) (45 pages)

- Pump Safety (9 pages)