Minimum continuous recommended flow, Pump operation precautions – Goulds Pumps 3296 EZMAG - IOM User Manual

Page 48

Commissioning, Startup, Operation, and Shutdown

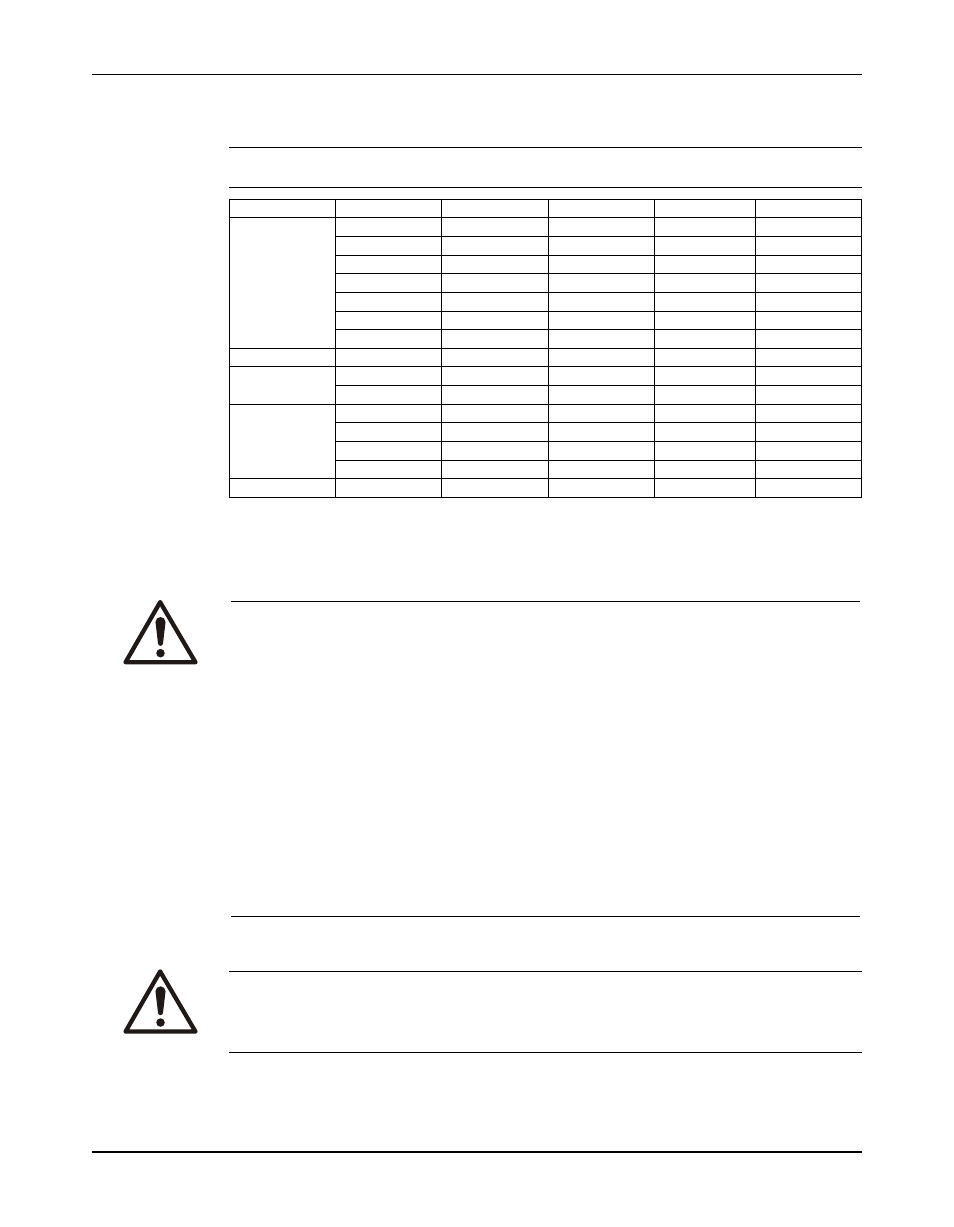

Minimum continuous recommended flow

Table 3: Minimum flow in GPM (m

3

/hr)

NOTICE:

These measurements are based on water with a Specific Gravity of 1.0 and a Specific Heat of 1.0.

Group

Size

3500 rpm

2900 rpm

1750 rpm

1450 rpm

S

1 x 1½ - 6

23 (5)

15 (4)

11 (3)

8 (2)

1 x 1½ - 6G

7.0 (1.6)

4.9 (1.1)

1.8 (0.4)

1.2 (0.27)

1½ x 3 - 6

30 (7)

25 (6)

15 (4)

13 (3)

2 x 3 - 6

56 (12.5)

47 (11)

28 (6)

23 (5)

1 x 1½ - 8

10 (2.5)

7 (2)

3 (1)

2 (1)

1 x 1½ - 8H

22 (5)

18 (4)

11 (2.5)

9 (2)

1½ x 3 - 8

34 (8)

29 (7)

17 (4)

14 (3)

S/M

2 x 3 - 8

74 (17)

61 (14)

37 (9)

20 (5)

M (8 in.)

3 x 4 - 7

157 (36)

127 (29)

78 (18)

64 (15)

3 x 4 - 8G

159 (36)

129 (30)

79 (18)

65 (15)

M (10 in.)

1 x 2 - 10

21 (5)

13 (3)

9 (2)

7 (2)

1½ x 3 - 10

41.5 (9)

35 (8)

21 (5)

17.5 (4)

2 x 3 - 10

78 (18)

65 (15)

38 (9)

31 (7)

3 x 4 - 10

173 (40)

144 (33)

86 (20)

72 (16)

M (13 in.)

1½ x 3 - 13

53 (12)

44 (10)

26 (6)

22 (5)

Pump operation precautions

General considerations

CAUTION:

• Vary the capacity with the regulating valve in the discharge line. Never throttle the flow from the

suction side since this can result in decreased performance, unexpected heat generation, and

equipment damage.

Do not overload the driver. Driver overload can result in unexpected heat generation and equipment

damage. The driver can overload in these circumstances:

• The specific gravity of the pumped fluid is greater than expected.

• The pumped fluid exceeds the rated flow rate.

• Do not operate pump past the maximum flow. For maximum flow refer to the pump performance

curve.

• Do not overload the driver. Driver overload can result in unexpected heat generation and equipment

damage. The driver can overload in these circumstances:

• The specific gravity of the pumped fluid is greater than expected.

• The pumped fluid exceeds the rated flow rate.

• Do not operate pump below hydraulic or thermal minimum flow. For hydraulic minimum flows refer

to technical manual and pump performance curve. To calculate thermal minimum flow, refer to HI

Centrifugal Pumps for Design and Application ANSI/HI 1.3-2000.

• Make sure to operate the pump at or near the rated conditions. Failure to do so can result in pump

damage from cavitation or recirculation.

Operation at reduced capacity

WARNING:

Never operate any pumping system with a blocked suction and discharge. Operation, even for a brief

period under these conditions, can cause confined pumped fluid to overheat, which results in a violent

explosion. You must take all necessary measures to avoid this condition. If pump becomes plugged shut

down and unplug prior to restarting pump.

46

Model 3296 EZMAG Installation, Operation, and Maintenance Manual