Alignment troubleshooting – Goulds Pumps 3296 EZMAG - IOM User Manual

Page 75

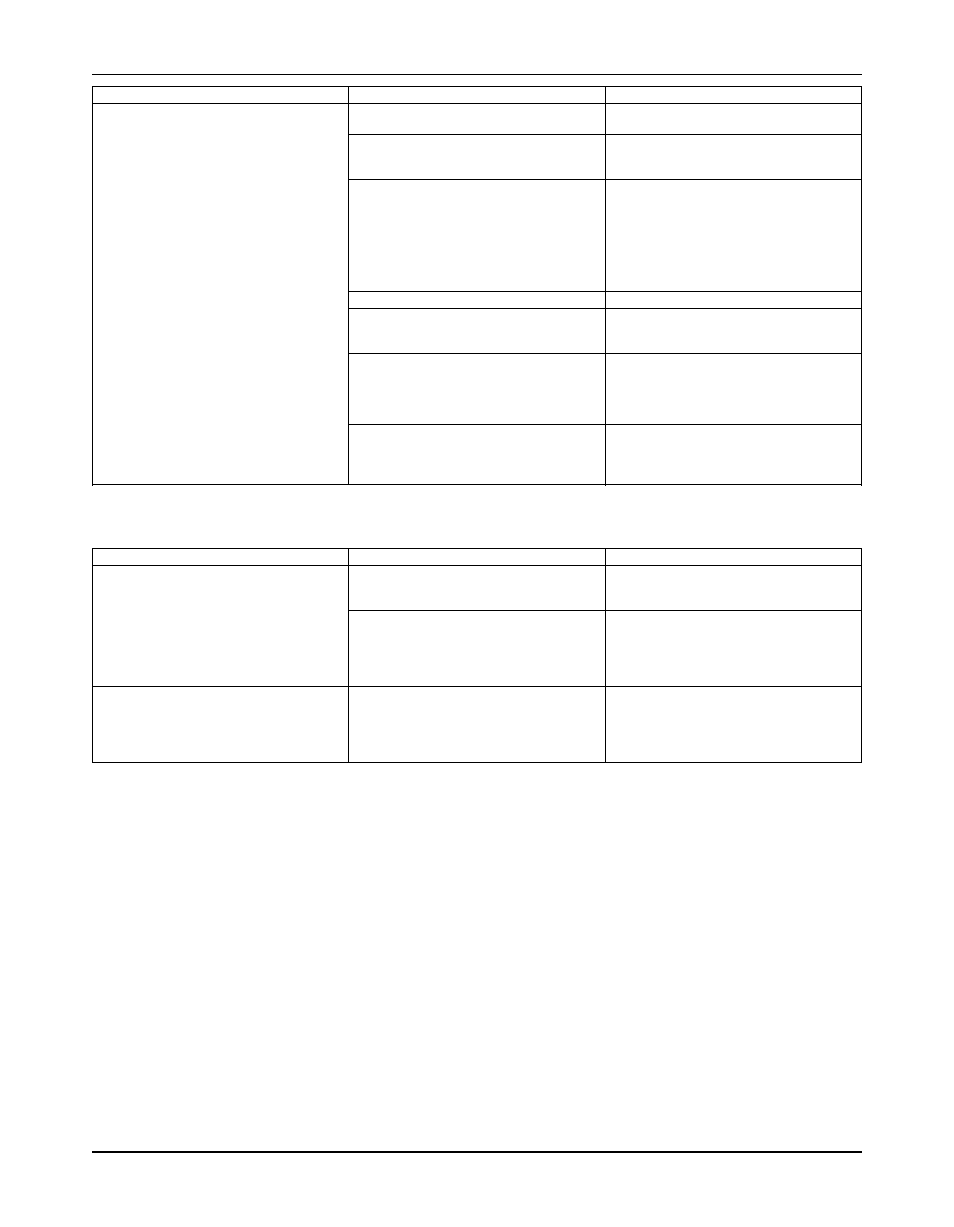

Troubleshooting

Symptom

Cause

Remedy

The condition monitoring device shuts

The sleeve and thrust bearings are dam-

Replace as required.

down the pump.

aged.

There is a plugged recirculation circuit.

Disassemble and remove the blockage.

Then determine and correct the cause of

the blockage.

There is recirculation liquid vaporization.

Correct all of these as necessary:

• Check the actual liquid temperature

versus the design temperature.

• Check the actual NPSH available

versus the design.

• Check the minimum flow require-

ment for the pump size.

The containment shell is damaged.

Replace as required.

The magnets are de-coupling.

Check the temperature and viscosity of

the pumped fluid. Check the magnets with

a breakaway torque test.

The pump is running dry.

• Check the control device for proper

operation.

• Check the suction line for blockage.

• Reprime the pump.

There is excessive motor power.

The system head is lower than the rating

and pumps too much liquid.

Check the rotating parts for binding and

wear. The liquid is heavier than expected.

Alignment troubleshooting

Symptom

Cause

Remedy

Horizontal (side-to-side) alignment cannot The driver feet are bolt-bound.

Loosen the pump's hold-down bolts, and

be obtained (angular or parallel).

slide the pump and driver until you

achieve horizontal alignment.

The baseplate is not leveled properly and 1. Determine which corners of the base-

is probably twisted.

plate are high or low.

2.

Remove or add shims at the appropri-

ate corners.

3.

Realign the pump and driver.

Vertical (top-to-bottom) alignment cannot The baseplate is not leveled properly and 1. Determine if the center of the base-

be obtained (angular or parallel).

is probably bowed.

plate should be raised or lowered.

2.

Level screws equally at the center of

the baseplate.

3.

Realign the pump and driver.

Model 3296 EZMAG Installation, Operation, and Maintenance Manual

73