Pump-to-driver alignment instructions – Goulds Pumps 3296 EZMAG - IOM User Manual

Page 25

Installation

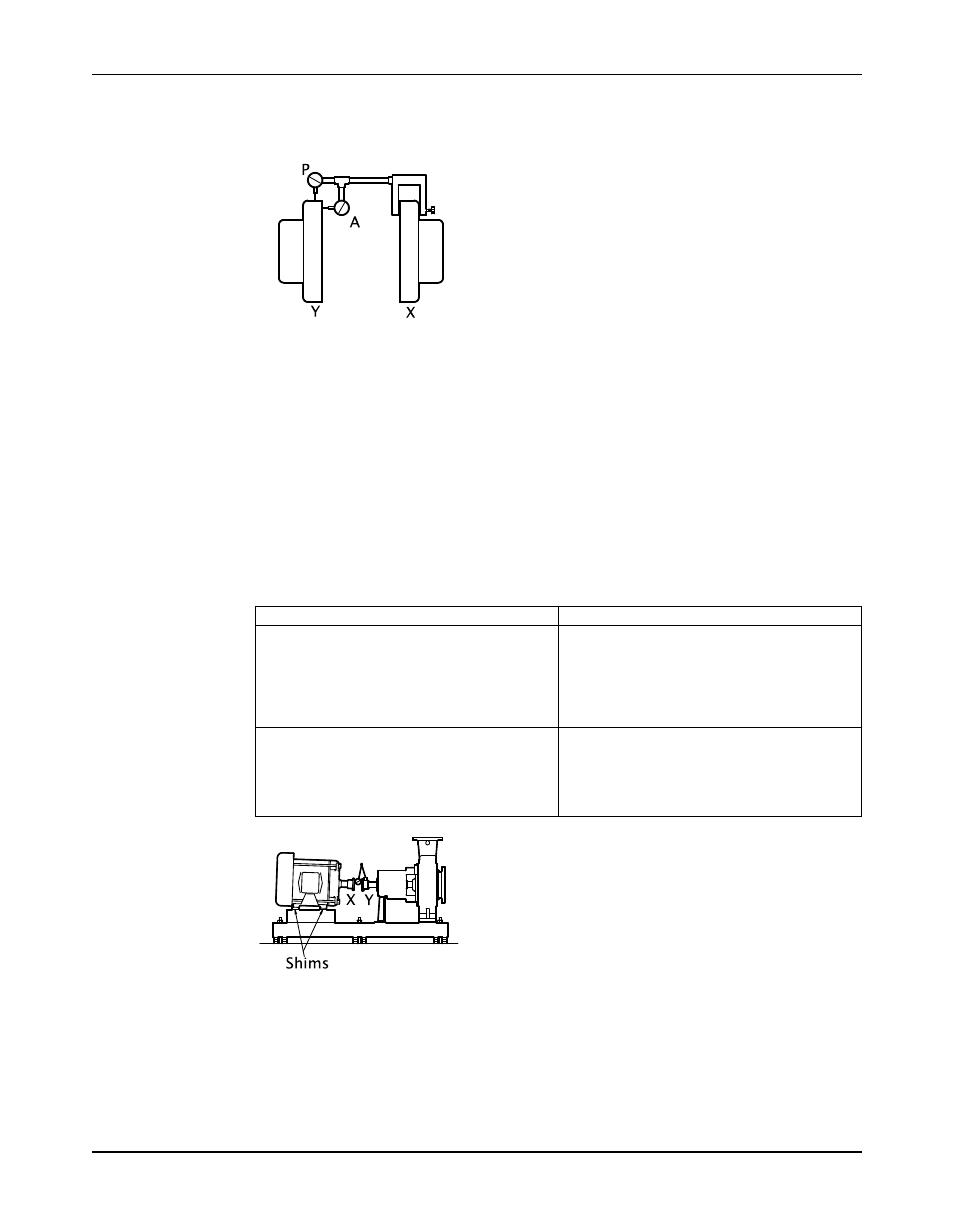

b) Attach the other indicator (A) so that the indicator rod comes into contact with the inner

end of the driver coupling half.

This indicator is used to measure angular misalignment.

2. Rotate the pump coupling half (X) in order to check that the indicators are in contact with

the driver coupling half (Y) but do not bottom out.

3. Adjust the indicators if necessary.

Pump-to-driver alignment instructions

Perform angular alignment for a vertical correction

Before you start this procedure, make sure that the dial indicators are properly attached for

measurement.

1. Set the angular alignment indicator to zero at the top-center position (12 o’clock) of the

driver coupling half (Y).

2. Rotate the indicator to the bottom-center position (6 o’clock).

3. Record the indicator reading.

When the reading value is...

Then...

Negative

The coupling halves are farther apart at the

bottom than at the top. Perform one of these

steps:

• Add shims in order to raise the feet of the

driver at the shaft end.

• Remove shims in order to lower the feet of the

driver at the other end.

Positive

The coupling halves are closer at the bottom than

at the top. Perform one of these steps:

• Remove shims in order to lower the feet of the

driver at the shaft end.

• Add shims in order to raise the feet of the

driver at the other end.

Figure 5: Side view of an incorrect vertical alignment

4. Repeat the previous steps until the permitted reading value is achieved.

Perform angular alignment for a horizontal correction

Before you start this procedure, make sure that the dial indicators are properly attached for

measurement.

Model 3296 EZMAG Installation, Operation, and Maintenance Manual

23